Stayed prestressed orthogonal space tube truss steel grid structure and manufacturing method thereof

A technology of orthogonal space and production method, applied in the direction of truss structure, truss beam, joist, etc., can solve the problem of increasing the cost of enclosure materials, and achieve the effect of less steel consumption and lower project cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

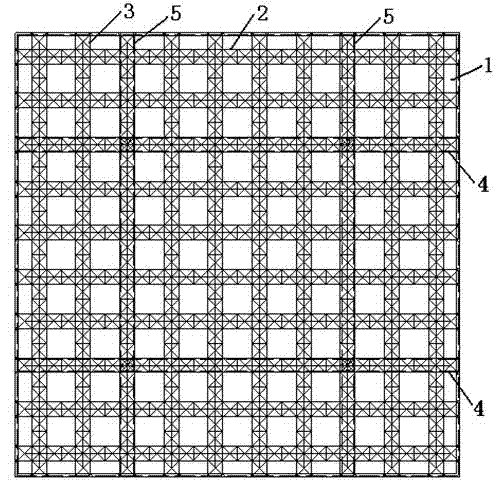

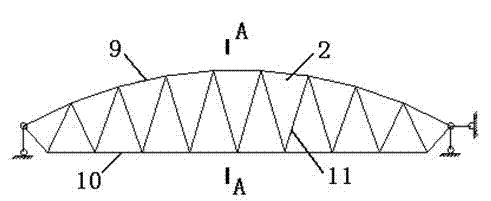

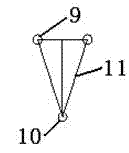

[0028] Example 1. Such as figure 1 , 2 As shown, the grid 1 is formed by a number of x-direction space pipe trusses 2 arranged along the x direction and several y-direction space pipe trusses 3 arranged along the y direction; There are two x-directed prestressed spatial tube trusses 4 along the x direction, and there are two y-directed prestressed spatial tube trusses 5 along the y direction. The two x-directed prestressed spatial tube trusses 4 and the two y-directed prestressed spatial tube The trusses 5 are orthogonal to each other; the prestressed steel cable 6 is arranged on the x-direction prestressed space pipe truss 4 and the y-direction prestressed space pipe truss 5, and the x-direction prestressed space pipe truss 4 and the y-direction prestressed space pipe truss 5. The intersection point of the lower chord is provided with a cable steering support frame 7. There are two support nodes 8 at both ends of the upper chord of each x-direction prestressed space pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com