Method for determining cycle performance of lithium ion battery

A lithium-ion battery and cycle performance technology, which is applied in the field of lithium-ion battery production and material selection, can solve the problems of structural changes in active materials, different service life of secondary batteries, and long time consumption, and achieve the effect of simplifying the judgment process and simple calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

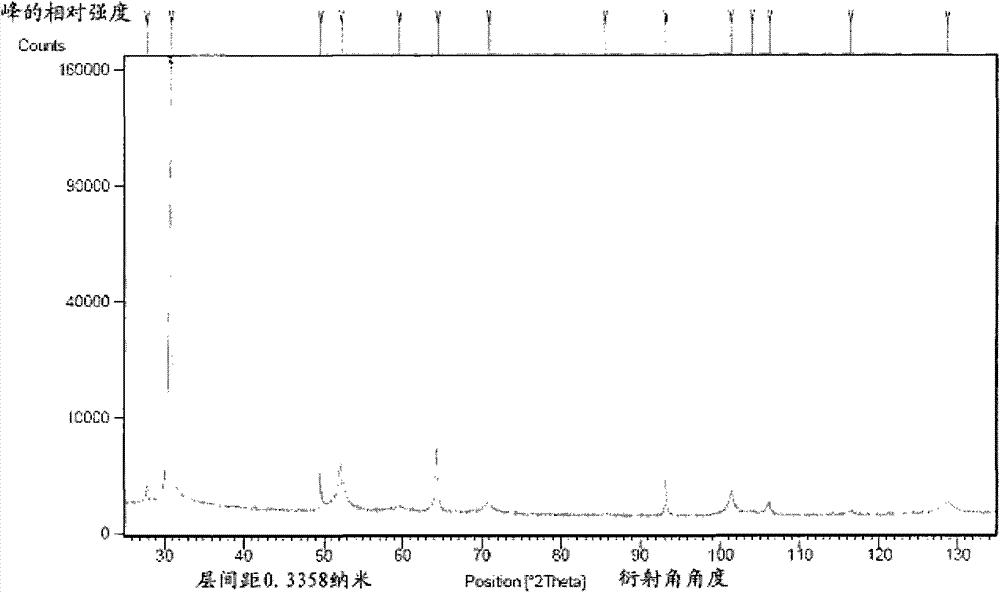

[0072] 1. To measure the XRD of the selected anode material, please refer to figure 1 The ray diffraction (XRD) test spectrum of negative electrode material shown, and draw interlayer spacing by interlayer spacing calculation formula (referring to formula 1-7), the interlayer spacing in embodiment one is 0.3358 nanometers, can be obtained by formula or by XRD directly calculated by the software;

[0073] 2. Weigh 100 grams of graphite, 2.5 grams of conductive agent, 1.5 grams of dispersant and 4 grams of thickener and dissolve them in a certain amount of water, and then apply them as required. After baking, the negative electrode sheet A required for the experiment is obtained. ;

[0074] 3. Weigh a certain amount of metal lithium sheet in proportion, remove the oxide layer on the surface as the counter electrode B, and assemble it with the pole piece A to form a half-cell for cycle performance testing. The cycle performance curve is as follows Figure 5 shown.

Embodiment 2

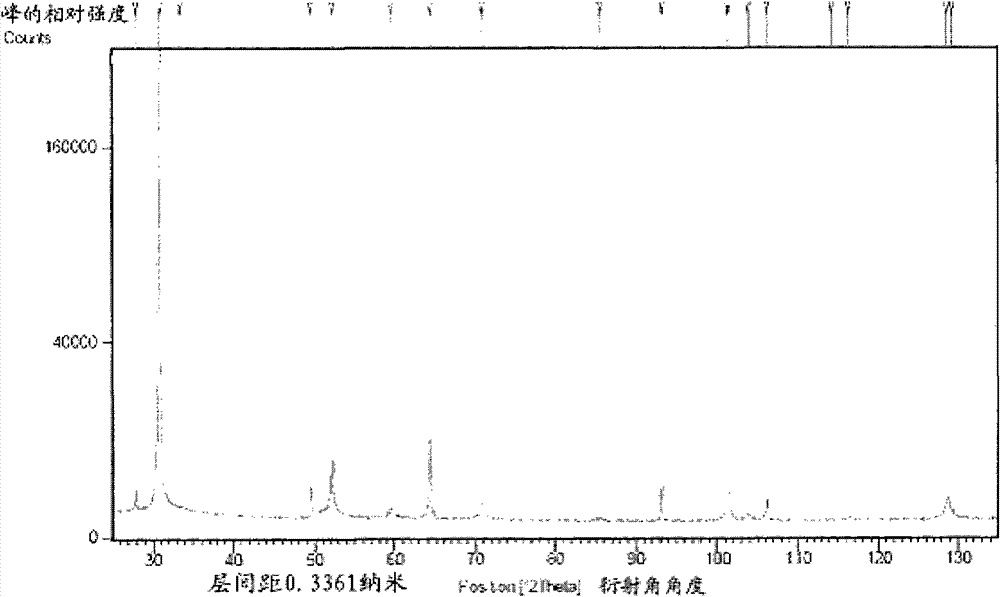

[0076] 1. To measure the XRD of the selected anode material, please refer to figure 2 The ray diffraction (XRD) test spectrum of negative electrode material shown, and draw interlayer spacing by interlayer spacing calculation formula (referring to formula 1-7), the interlayer spacing among the embodiment two is 0.3361 nanometer, can be obtained by formula or by XRD directly calculated by the software;

[0077] 2. Weigh 100 grams of graphite, 2.5 grams of conductive agent, 1.5 grams of dispersant and 4 grams of thickener and dissolve them in a certain amount of water, and then apply them as required. After baking, the negative electrode sheet A required for the experiment is obtained. ;

[0078] 3. Weigh a certain amount of metal lithium sheet in proportion, remove the oxide layer on the surface as the counter electrode B, and assemble it with the pole piece A to form a half-cell for cycle performance testing. The cycle performance curve is as follows Figure 6 shown.

Embodiment 3

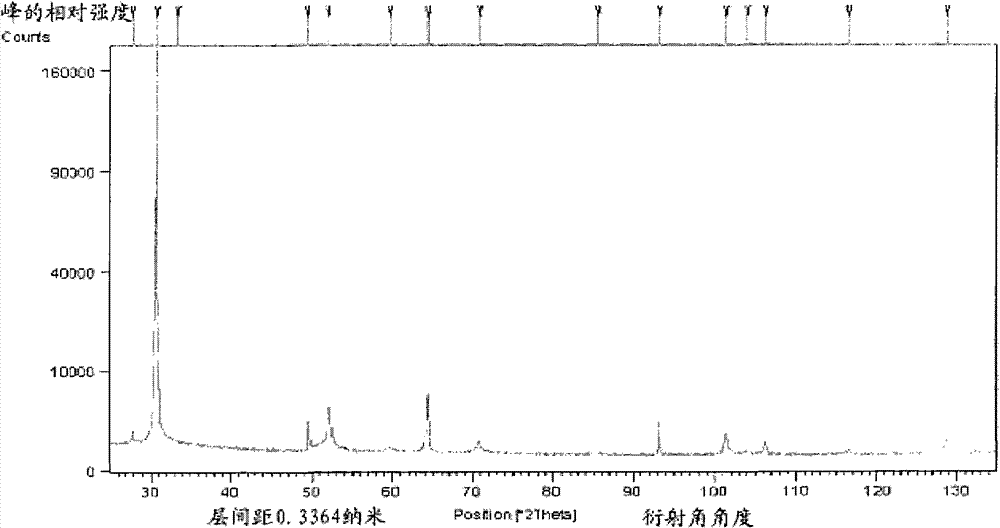

[0080] 1. To measure the XRD of the selected anode material, please refer to image 3 The ray diffraction (XRD) test pattern of negative electrode material shown, and draw interlayer spacing by interlayer spacing calculation formula (referring to formula 1-7), the interlayer spacing among the embodiment three is 0.3364 nanometers, can be obtained by formula or by XRD directly calculated by the software;

[0081] 2. Weigh 100 grams of graphite, 2.5 grams of conductive agent, 1.5 grams of dispersant and 4 grams of thickener and dissolve them in a certain amount of water, and then apply them as required. After baking, the negative electrode sheet A required for the experiment is obtained. ;

[0082] 3. Weigh a certain amount of metal lithium sheet in proportion, remove the oxide layer on the surface as the counter electrode B, and assemble it with the pole piece A to form a half-cell for cycle performance testing. The cycle performance curve is as follows Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com