Manufacturing method of piezoelectric actuator

A technology for piezoelectric actuators, manufacturing methods, application in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, etc. direction, which can solve problems such as poor driving of piezoelectric actuators and inability to maintain insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

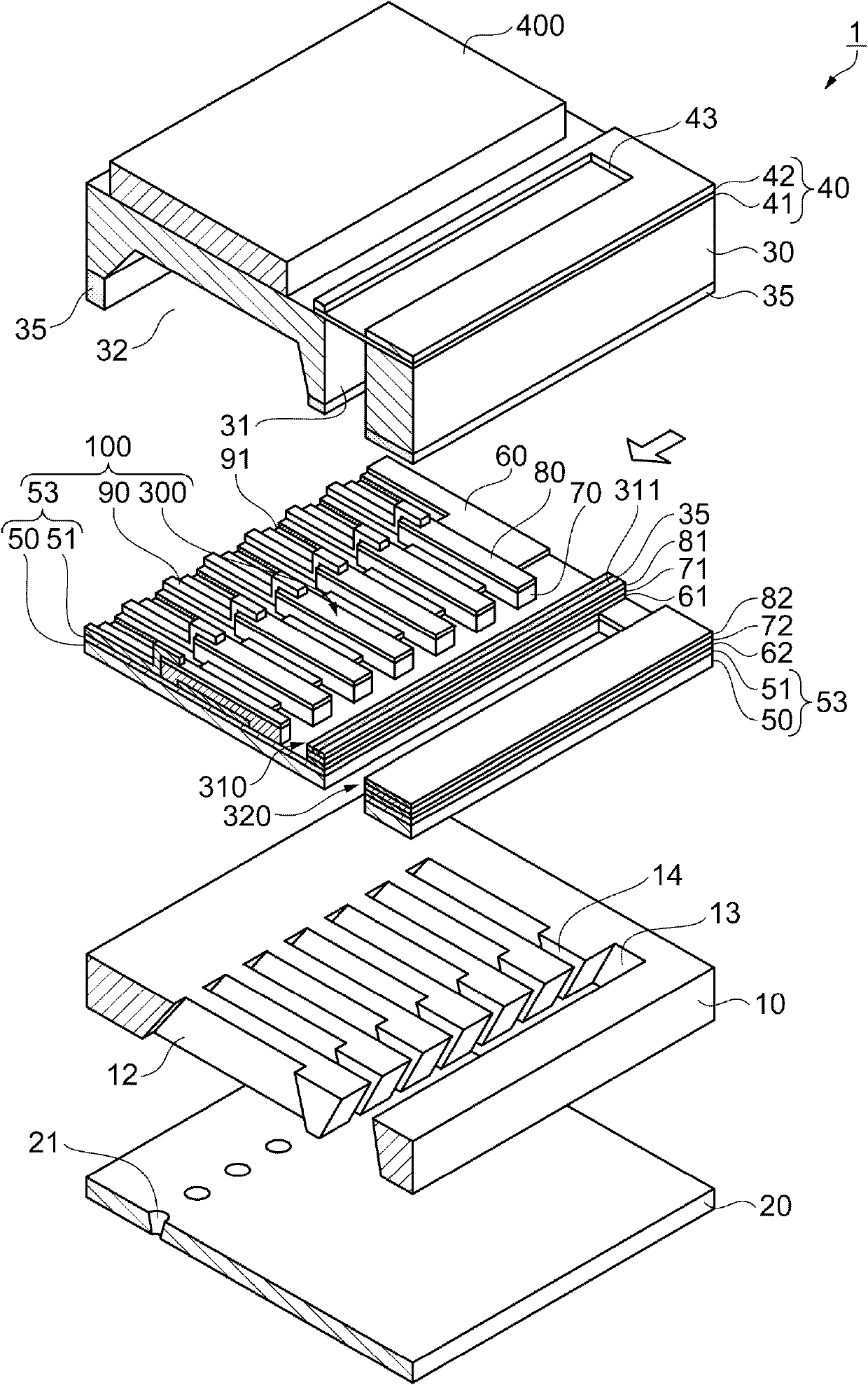

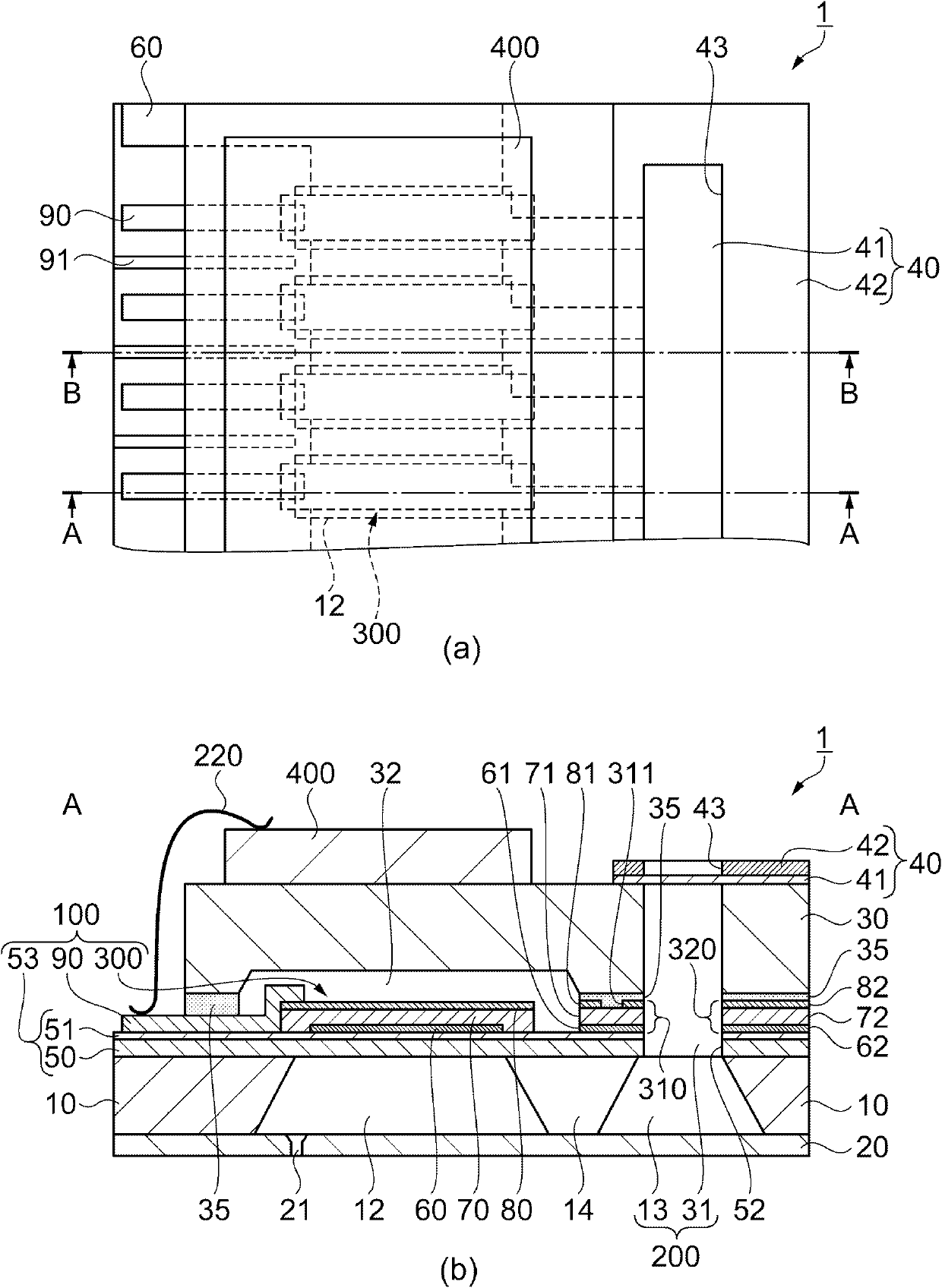

[0035] Embodiments will be described in detail below with reference to the drawings.

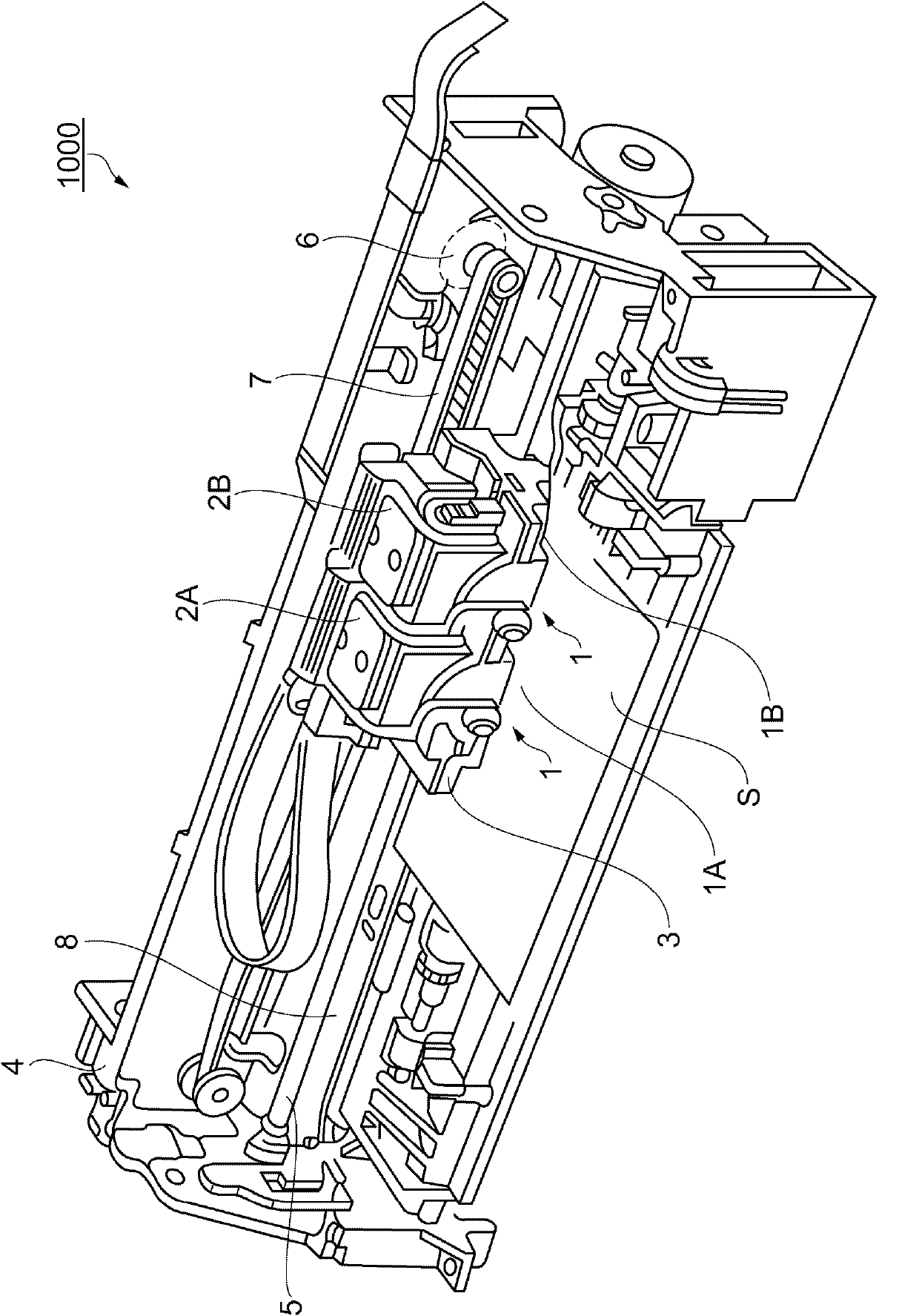

[0036] figure 1 It is a schematic diagram showing an example of an ink jet recording device 1000 as a liquid ejecting device, which includes an ink jet recording head 1 as a liquid ejecting head, and the recording head 1 includes a piezoelectric actuator.

[0037] Such as figure 1 As shown, an ink jet recording apparatus 1000 includes recording head units 1A and 1B.

[0038] In the recording head units 1A and 1B, cartridges 2A and 2B constituting an ink supply mechanism are detachably provided. A carriage 3 on which the recording head units 1A and 1B are mounted is provided on a carriage shaft 5 attached to the apparatus main body 4 so as to be able to move in the axial direction.

[0039] The recording head units 1A and 1B eject, for example, a black ink composition and a color ink composition, respectively. The driving force of the drive motor 6 is transmitted to the carriage 3 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com