Die for producing small-sized bending part

A technology of bending parts and molds, which is applied in the field of molds for the production of small bending parts. It can solve the problems of reduced production efficiency, difficult control of size, and unsmooth demoulding of products, so as to improve production efficiency, demould without deformation, and demould easily. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

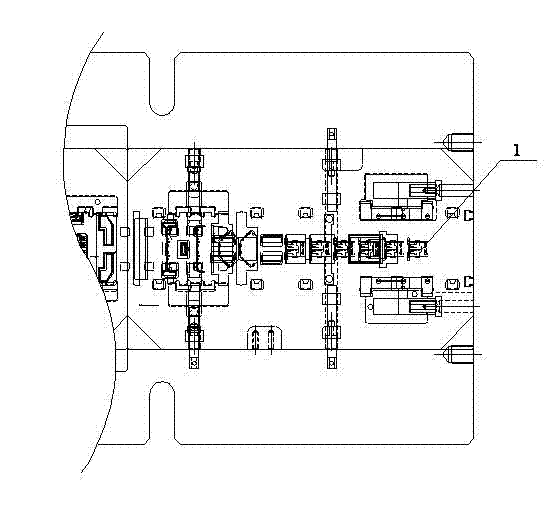

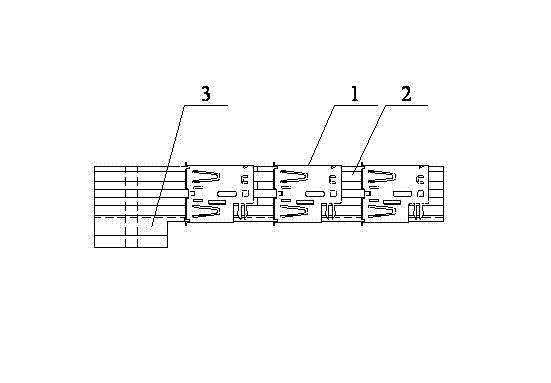

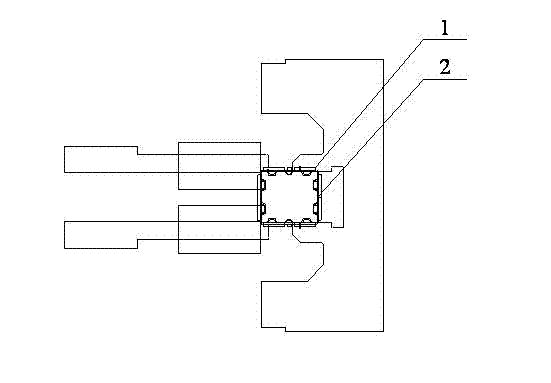

[0015] combine Figure 1 to Figure 3 A mold for producing small-sized curved parts according to the present invention is widely used in electronic and instrument products by adopting continuous stamping process to manufacture curved parts such as USB interface housings. The punch consists of the upper die base, the upper backing plate for the punch, the punch fixing plate and the punch used for stamping from top to bottom. The punch is fixed on the corresponding position of the punch fixing plate according to the stamping process sequence. The die is fixedly connected from top to bottom by the lower backing plate, lower die base and die feet, and the die parts that match the punches on the punch are fixed on the corresponding positions of the lower backing plate in accordance with the stamping process sequence. Both punch and die are installed on the punching machine.

[0016] The strip-shaped thin steel strip is located between the punch and the die of the mold. The punch o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com