An automatic grinding and cutting equipment for engine rocker shaft

A rocker shaft and engine technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of high labor intensity and low processing efficiency of rocker shafts, and achieve low labor intensity and automation. High and efficient work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

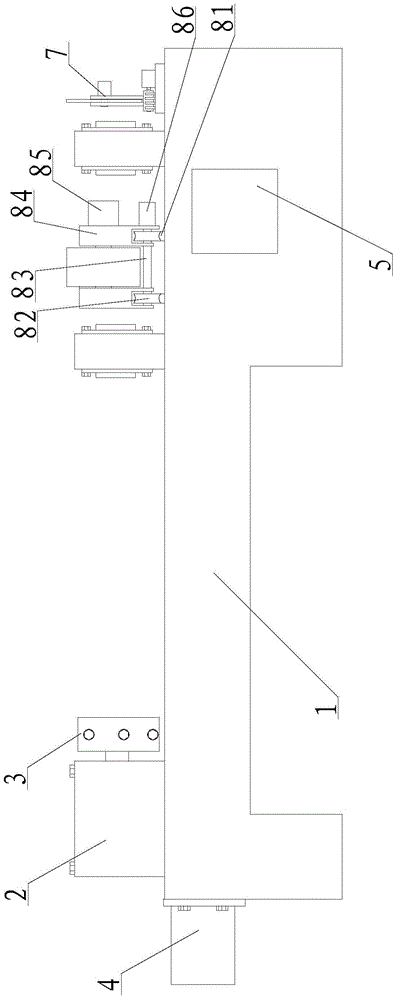

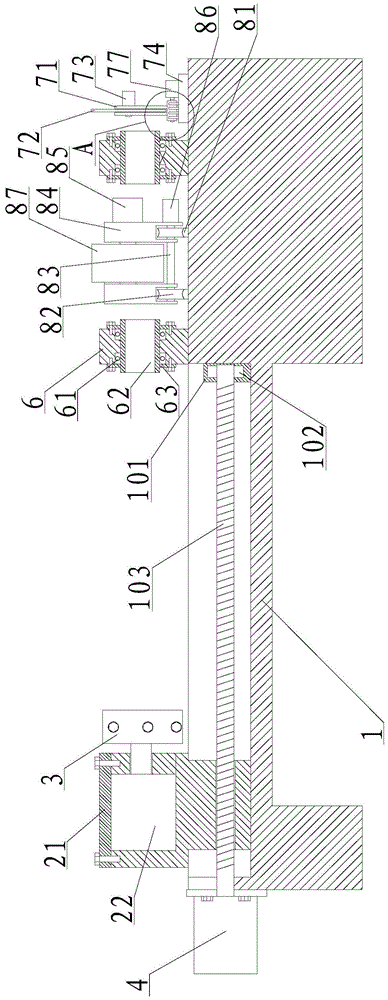

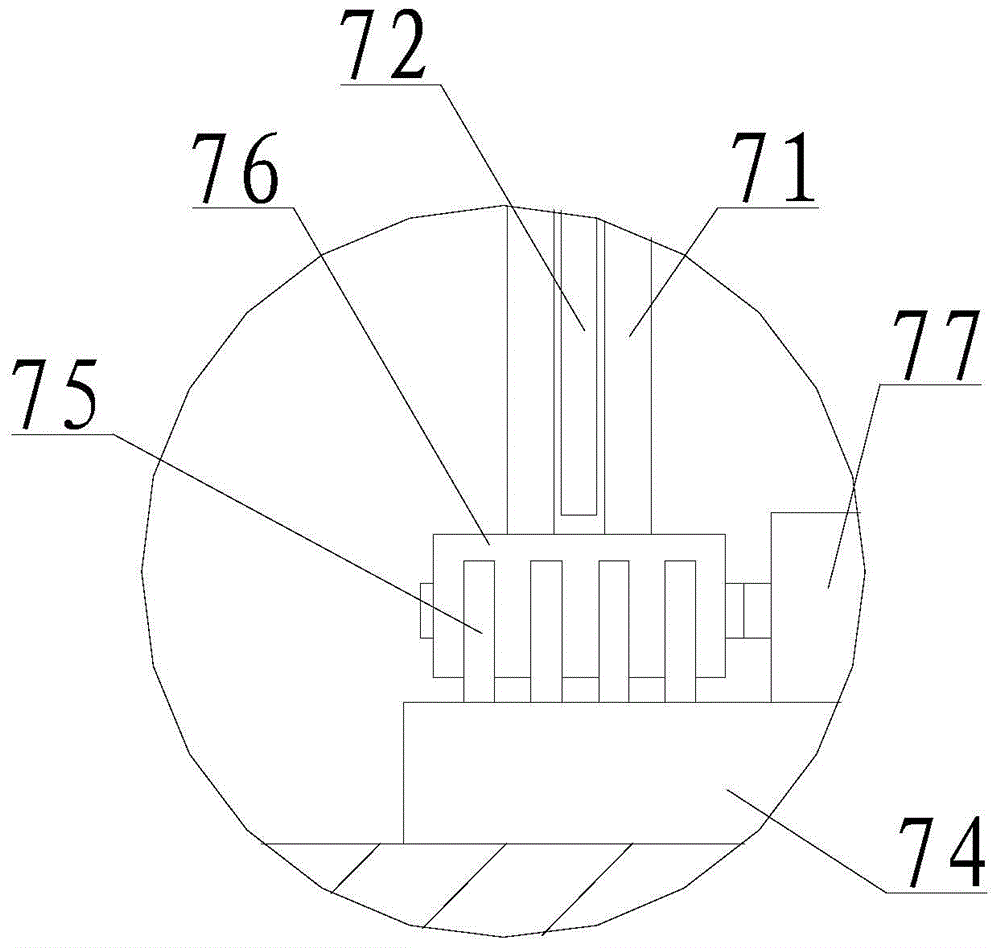

[0026] refer to figure 1 , figure 2 , image 3 with Figure 4 , the present invention is an automatic grinding and intercepting equipment of engine rocker arm shaft, including worktable 1, feeding table 2, lead screw 103, clamping claw plate 3, feeding motor 4, control box 5, support seat 6, cutting device 7 and the derusting mechanism, the workbench 1 is equipped with a feeding table 2, and the feeding table 2 is equipped with a material transfer motor 22. The cover plate 21 is installed by bolts, the lower part of the feeding table 2 is provided with a displacement hole, the left side of the workbench 1 is fixed with a feed motor 4 by bolts, and the feed motor 4 is connected with the lead screw 103, and several supports are arranged on the workbench 1 seat 6, two bearings 61 are installed on the support seat 6, the side of the bearing 61 is fixed with a bearing cover plate 63 through screw thread, the rotating cylinder 62 is sleeved in the bearing 61, and the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com