Anti-sticking material device with hole-punching and hole-flanging functions

An anti-sticking material and hole-turning technology, which is applied in the field of stamping dies, can solve the problems such as waste sticking to the mouth of the turning-hole, no concave die, and inability to remove, etc., and achieves the effect of improving the yield rate, convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific implementation methods.

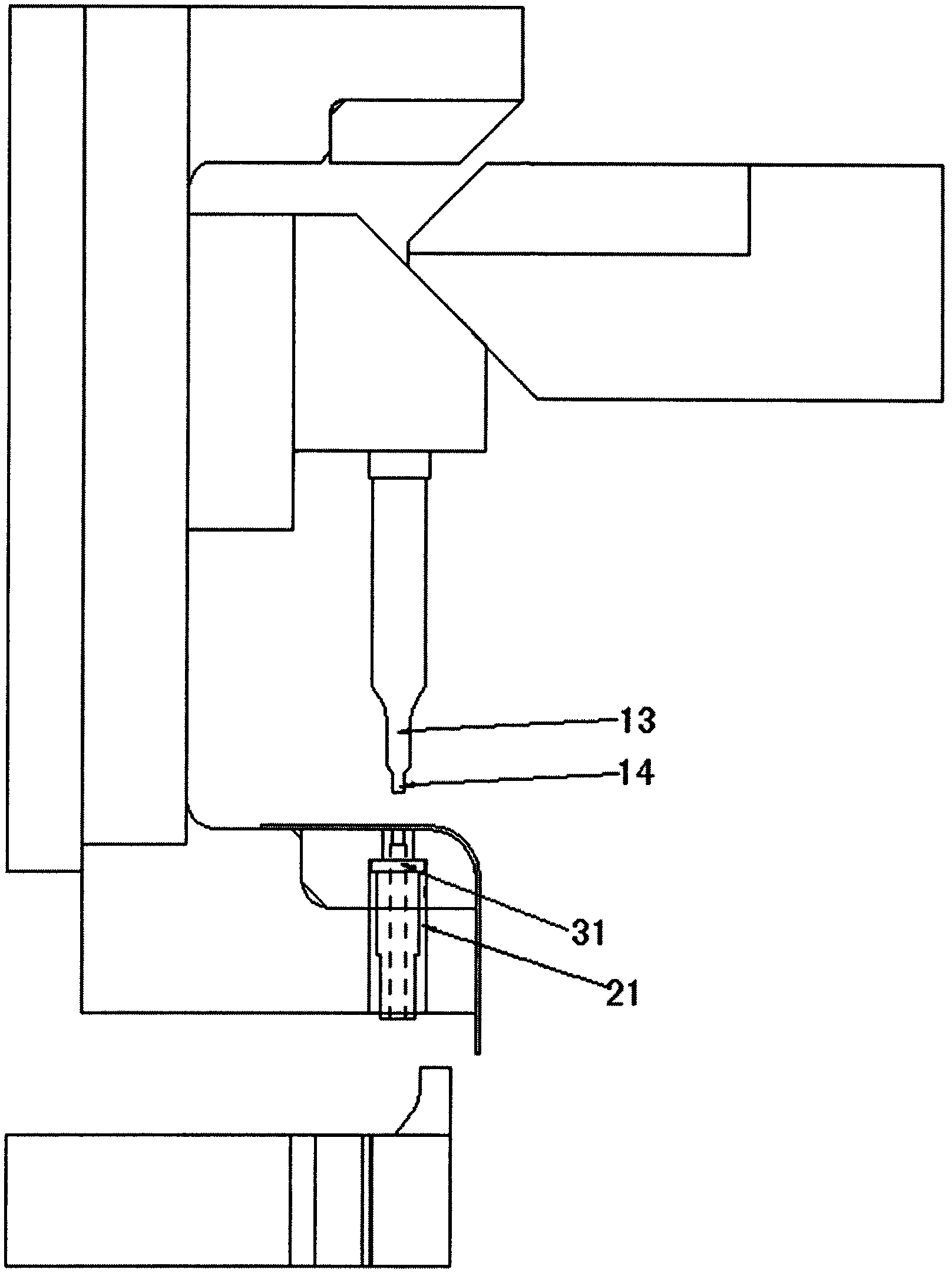

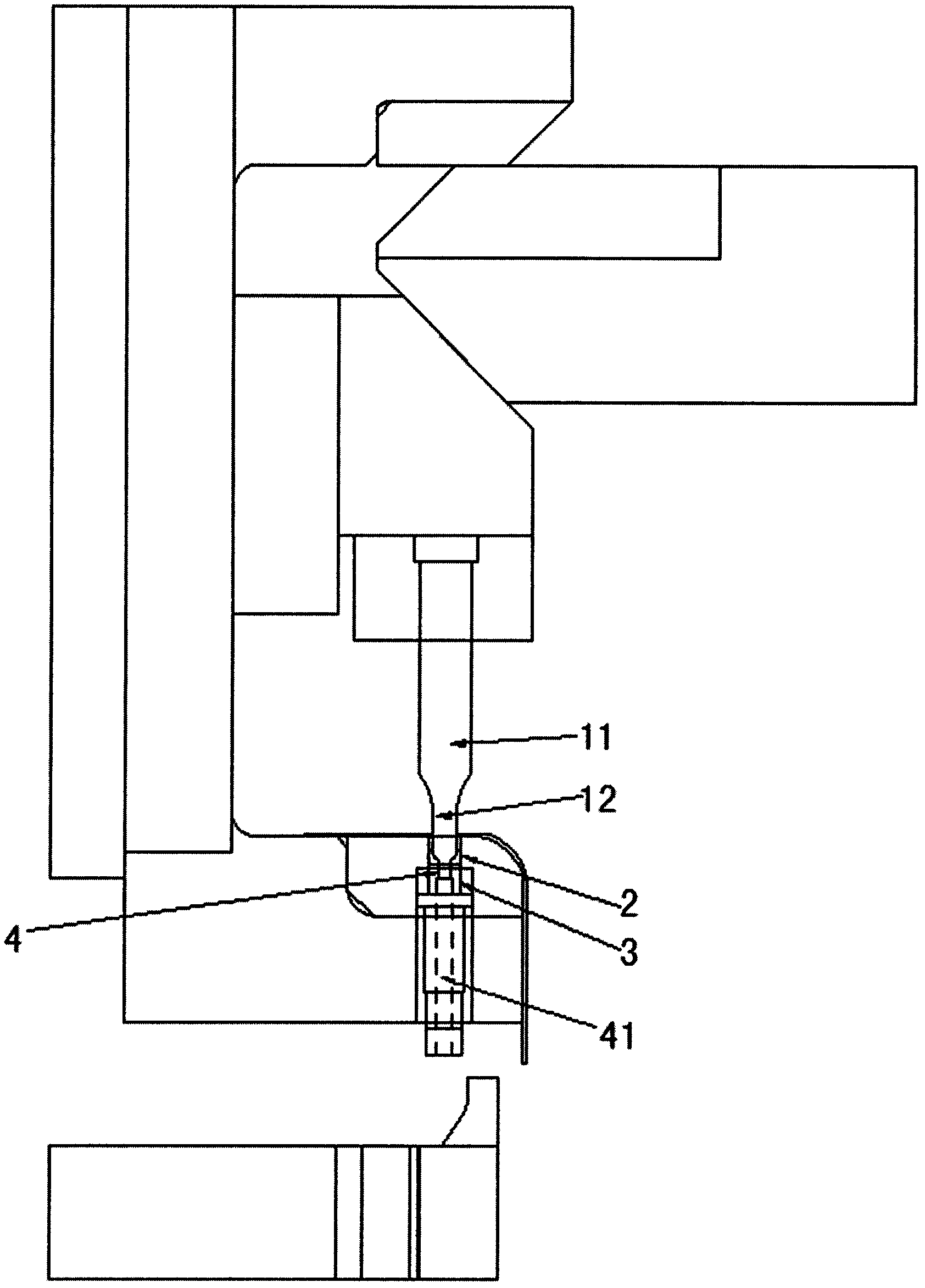

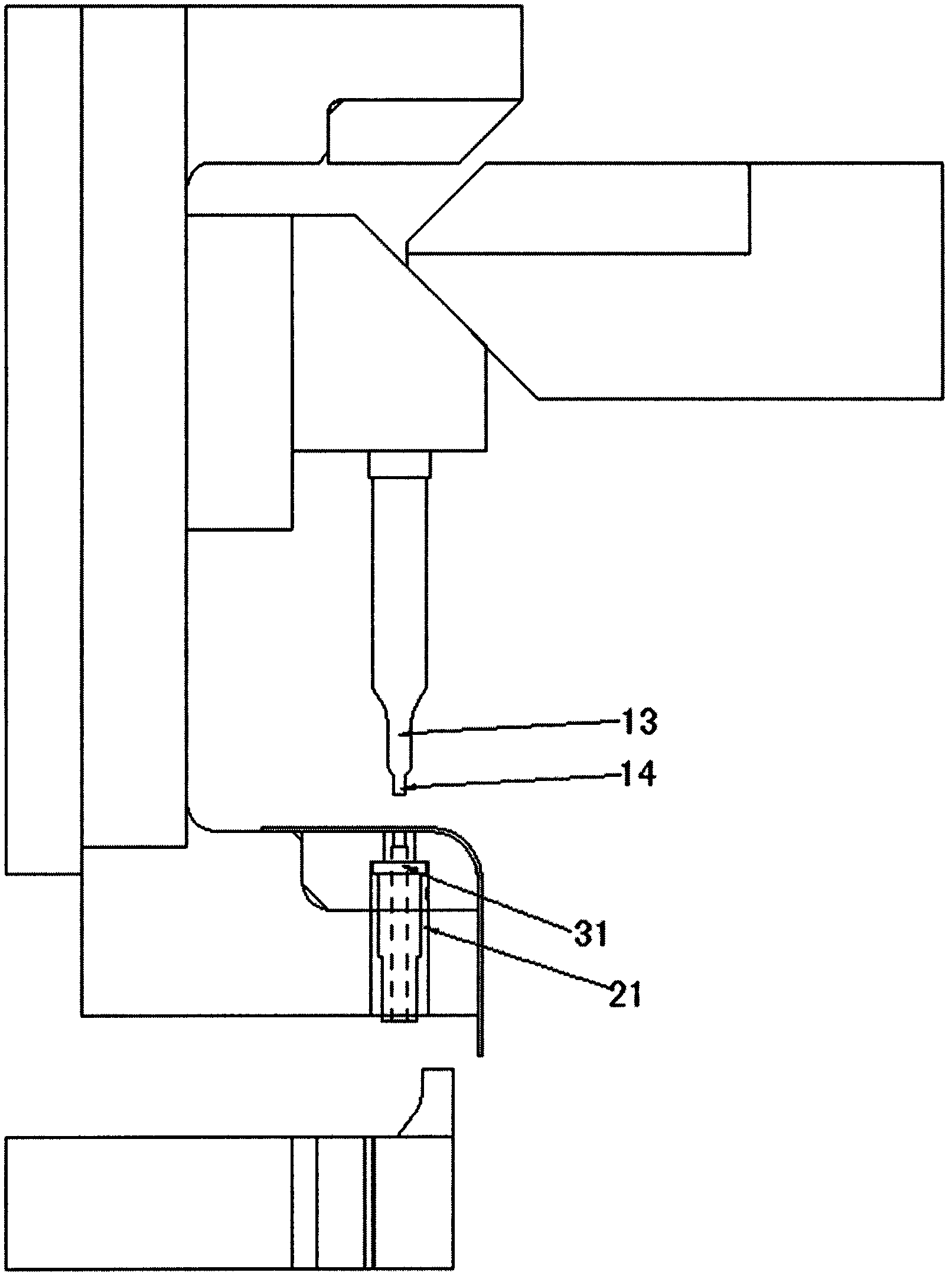

[0014] As shown in the figure, a punching and turning hole anti-sticking material device includes a punch, a die, turning the hole and removing the block 3,

[0015] Described punch comprises cutter bar 11 and the cutter head 12 that is connected with cutter bar 11, and described cutter head 12 comprises the front portion cutter head 13 that is used for punching and is used for the main body part 14 of turning hole, and the cylinder of main body part 14 The diameter of the body part is greater than the diameter of the front part cutter head 13 cylindrical parts, the transition connection part of the front part cutter head 13 and the main body part 14 is an outwardly convex arc shape, and the transition connection part of the cutter bar 11 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com