Uvioresistant BOPP (Biaxially Oriented Polypropylene) film and preparation process thereof

A technology of polypropylene film and biaxial stretching, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., which can solve the problem of not being able to protect the printed matter in the film product from ultraviolet damage, low transparency of the film, and limited application and other issues to achieve low cost, prevent degradation, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

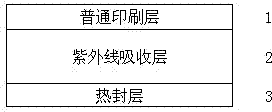

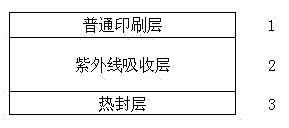

[0025] The heat-sealing layer and the ordinary printing layer add additives according to the existing formula, that is, the components of the ordinary printing layer are 3% anti-blocking masterbatch and 97% homopolypropylene by weight percentage, and the components of the heat-sealing layer are by weight The percentages are calculated as 3% anti-blocking masterbatch and 97% polypropylene copolymer or polypropylene copolymer.

[0026] The formula of the ultraviolet absorbing layer is calculated by weight percentage as 1% ultraviolet absorbing masterbatch, 2% antistatic masterbatch, and 97% homopolypropylene.

[0027] The UV absorbing masterbatch is a mixture of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole and copolymerized polypropylene, and the weight ratio of the two is 3.5-4.0 : 6.5-6.0.

[0028] According to the following production process for production:

[0029] a. UV-absorbing layered raw material homopolypropylene, antistatic masterbatch, and UV-ab...

Embodiment 2

[0035] Add additives to the heat-sealing layer and ordinary printing layer according to the existing formula. The formula of the ultraviolet absorbing layer is 2% ultraviolet absorbing masterbatch, 3% antistatic masterbatch, and 95% homopolypropylene.

[0036] The UV absorbing masterbatch is a mixture of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole and copolymerized polypropylene, and the weight ratio of the two is 3.5︰6.0 ; According to 4% of the weight of the UV-absorbing masterbatch, add a UV stabilizer, that is, a hindered amine light stabilizer.

[0037] According to the following production process for production:

[0038] a. UV-absorbing layered raw material homopolypropylene, antistatic masterbatch, and UV-absorbing masterbatch are sent to the main extruder to be heated into a molten state after drying and proportioning; heat-sealing layer raw material binary copolymerized polypropylene and anti-blocking masterbatch The common printing layer raw mat...

Embodiment 3

[0046] Add additives to the heat-sealing layer and ordinary printing layer according to the existing formula. The formula of the ultraviolet absorbing layer is 3% ultraviolet absorbing masterbatch, 2% antistatic masterbatch, and 95% homopolypropylene. The UV absorbing masterbatch is a mixture of 2-(2'-hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole and copolymerized polypropylene, the weight ratio of the two is 4.0︰6.5 ; According to 5% of the weight of the UV-absorbing masterbatch, add a UV stabilizer, that is, a hindered amine light stabilizer.

[0047] According to the following production process for production:

[0048] a. UV-absorbing layered raw material homopolypropylene, antistatic masterbatch, and UV-absorbing masterbatch are sent to the main extruder to be heated into a molten state after drying and proportioning; heat-sealing layer raw material binary copolymerized polypropylene and anti-blocking masterbatch The common printing layer raw material, copoly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap