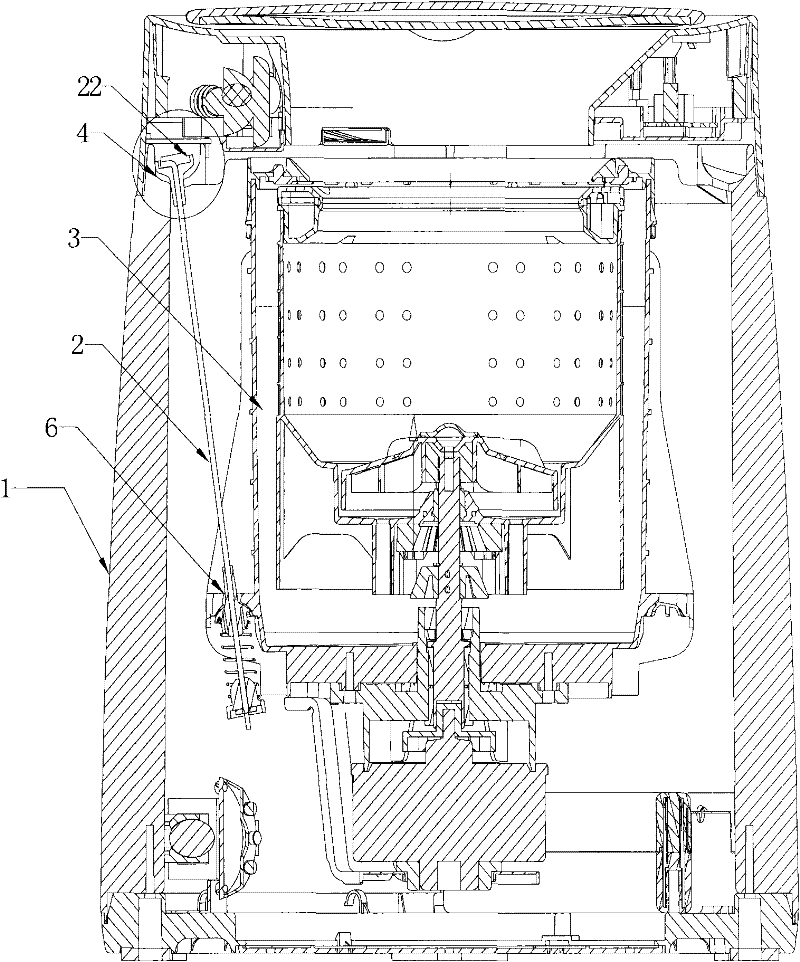

Anti-drop device for shock-absorbing hanging rod of small buoyancy-type washing machine

An anti-off device and washing machine technology, which is applied in the field of washing machines, can solve the problems affecting the normal operation of the washing machine and the hanger protruding out, and achieve the effect of convenient installation and maintenance, stable shielding plate, and anti-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

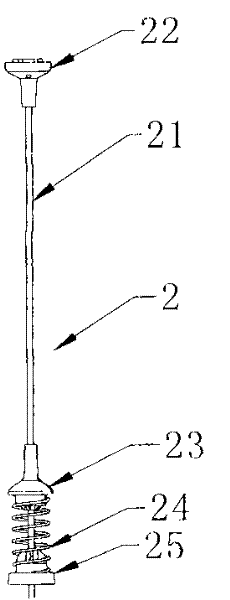

Method used

Image

Examples

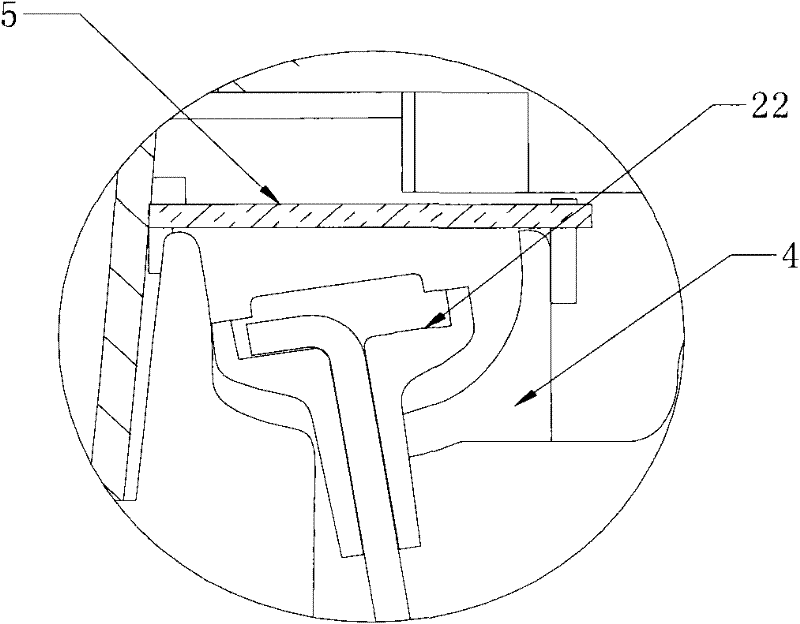

Embodiment 1

[0023] like Figure 5 As shown, another engaging structure of the shielding plate 5 is as follows: a protrusion protruding from the outside of the casing is arranged on the shielding plate, and a boss close to the hanging seat is arranged on the box body at the position of the hanging seat, and the boss is opposite to the hanging seat. One side is provided with an inwardly concave notch, the height of the bottom of the notch is on the same water level as the baffle plate, the high bottoms on both sides of the notch are lower than the height of the baffle plate, when the bump on the baffle plate turns to the position of the notch, press down to cover The plate makes the protrusion 52 snap into the gap to complete the positioning of the shielding plate. The structure of this solution is simple, and the existing structure on the box body can be used to realize the blocking purpose of the upper ball seat, and no corresponding engaging parts need to be added.

Embodiment 2

[0025] The content of the technical solution is the same as that of the first embodiment, except that the circular shield is replaced by a rectangular slat-shaped shield. Due to the reduced size of this solution, the operation is more utilized.

Embodiment 3

[0027] A fixing hole is arranged on the side opposite to the shaft hole 53 on the shielding plate 5, and a fixing column is arranged on the box body 1. The top of the fixing column is threaded. Align the fixing hole with the fixing rod and pass it on the fixing post, and then use the nut to fix the shielding plate on the fixing post. After the upper ball seat is installed in the hanging seat like this, the shielding plate has just formed a stable shielding surface. This solution adapts to different box structures, and utilizes the elasticity of the baffle plate and the characteristics of nut fixing, so that the top of the fixing column can face up or down, which is convenient and adapts to local conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com