Patents

Literature

61results about How to "Prevent radial rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

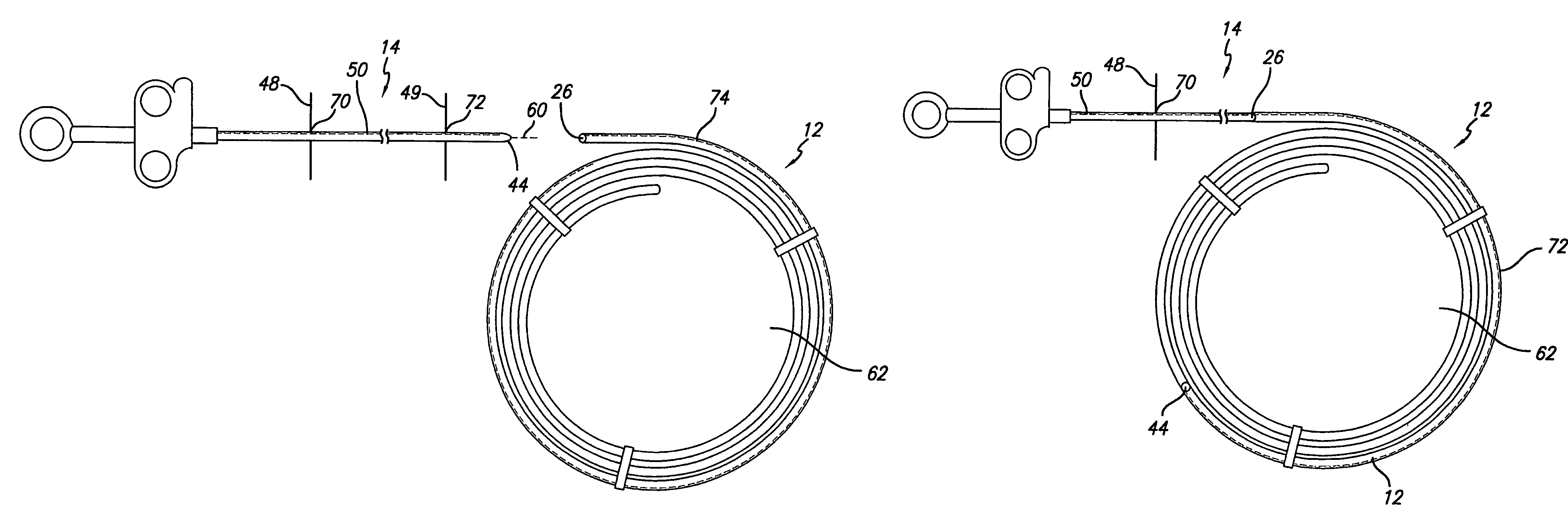

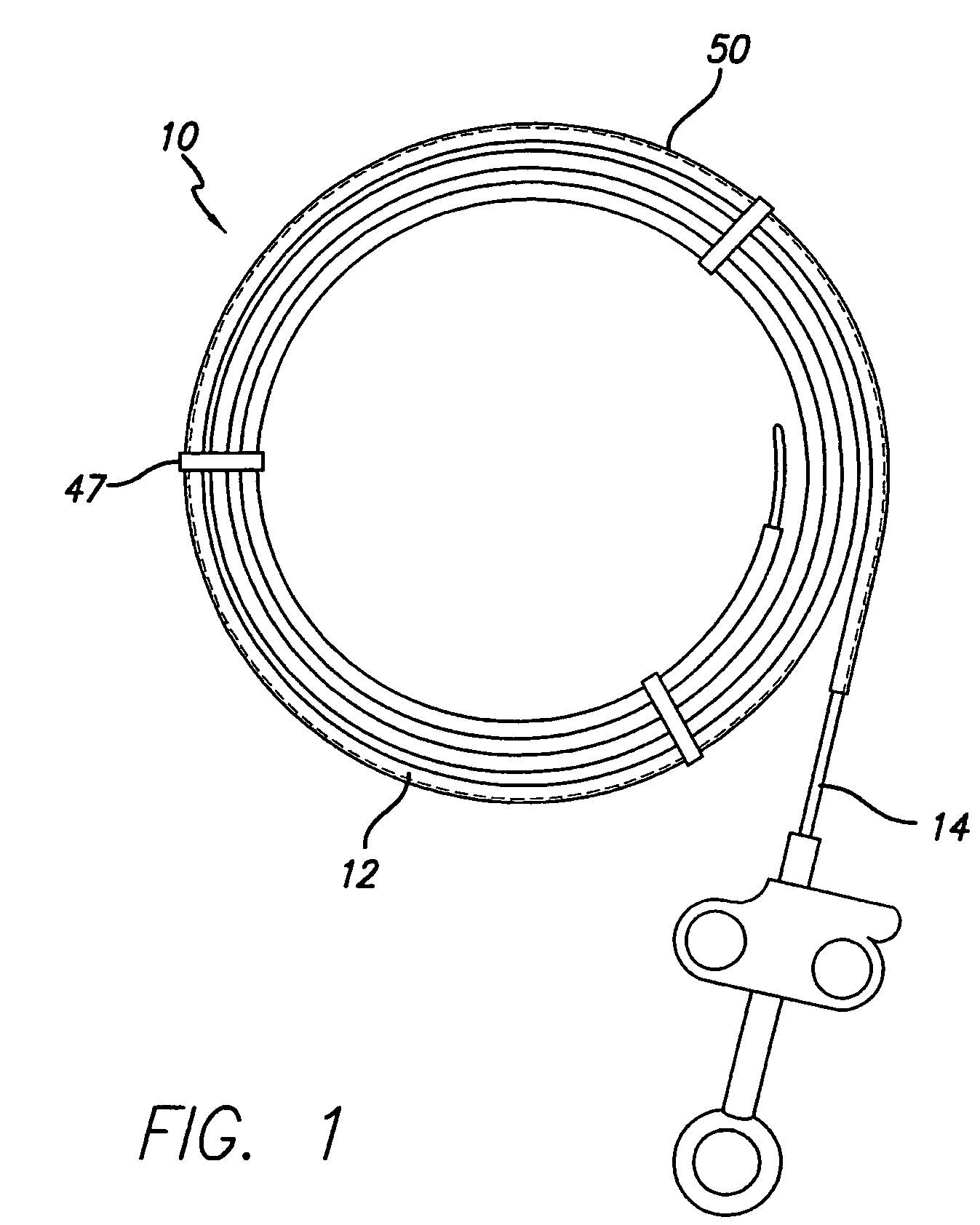

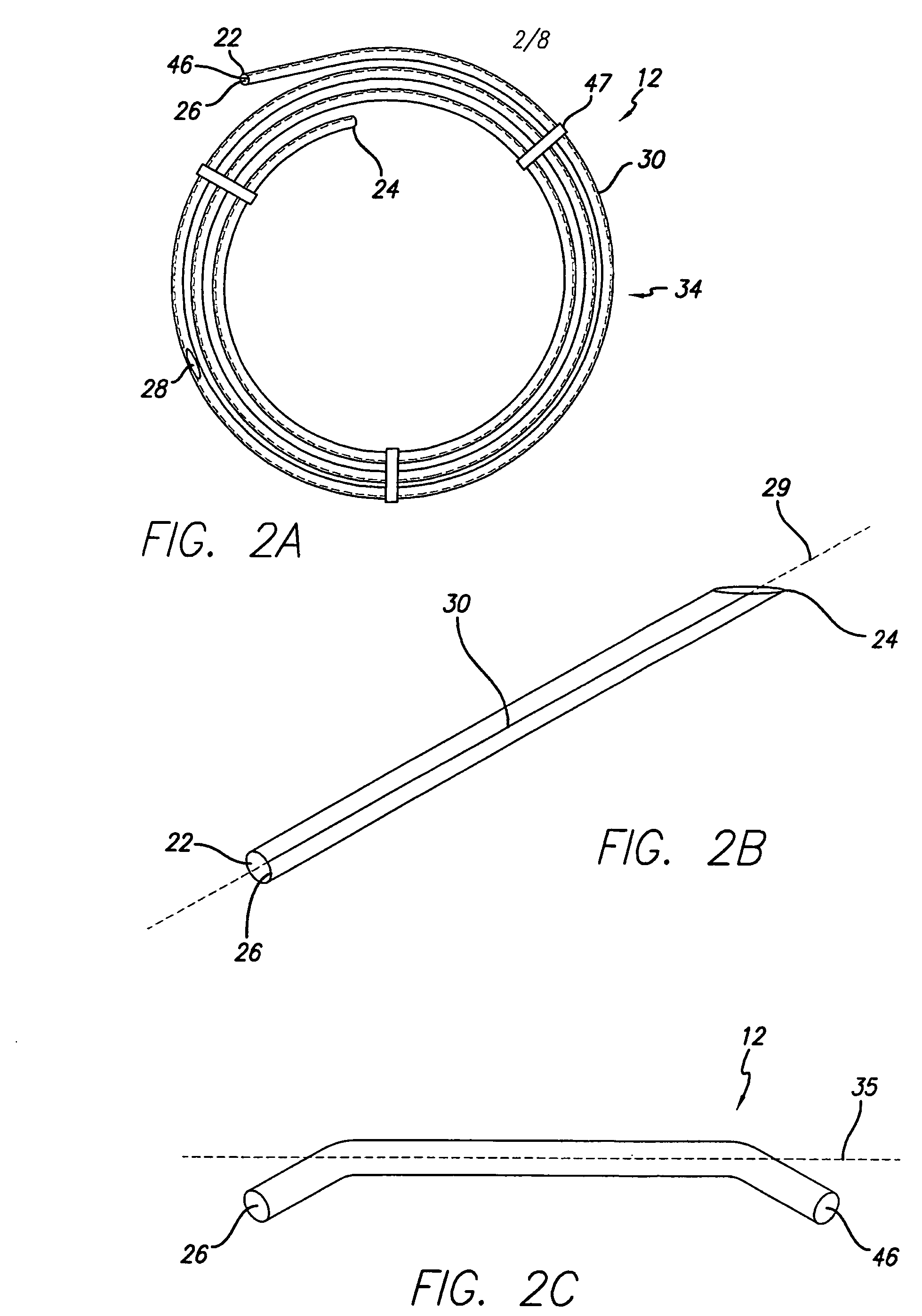

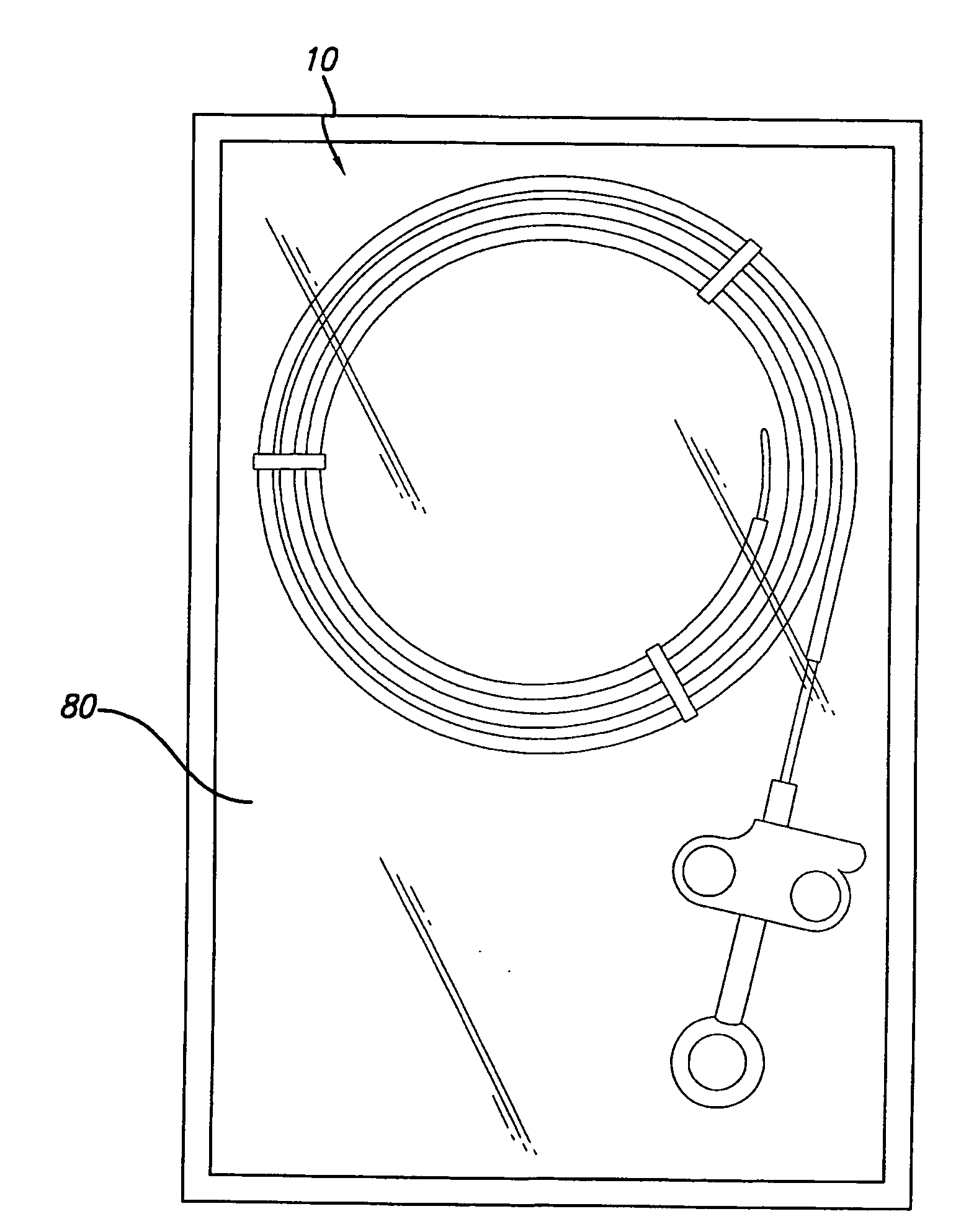

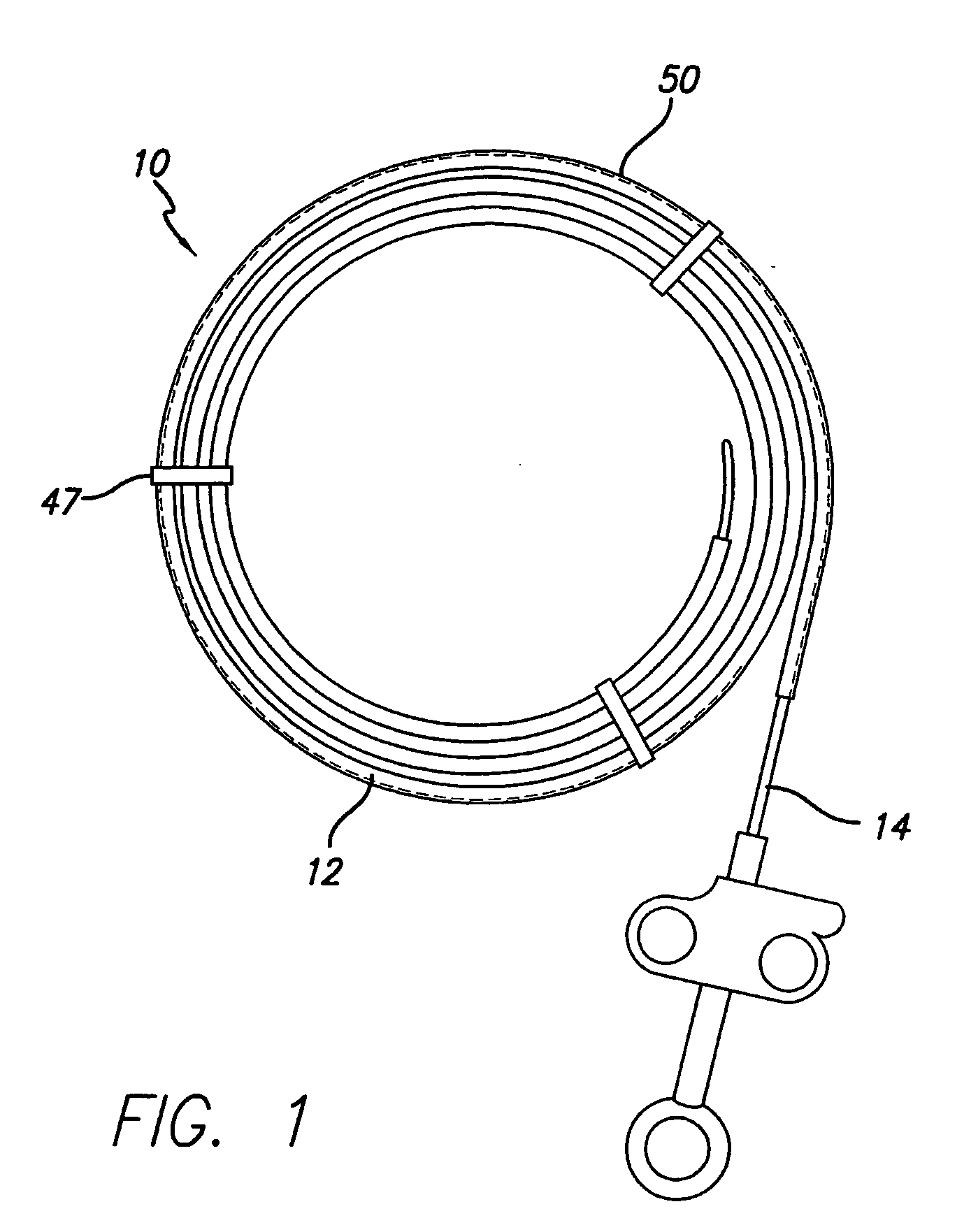

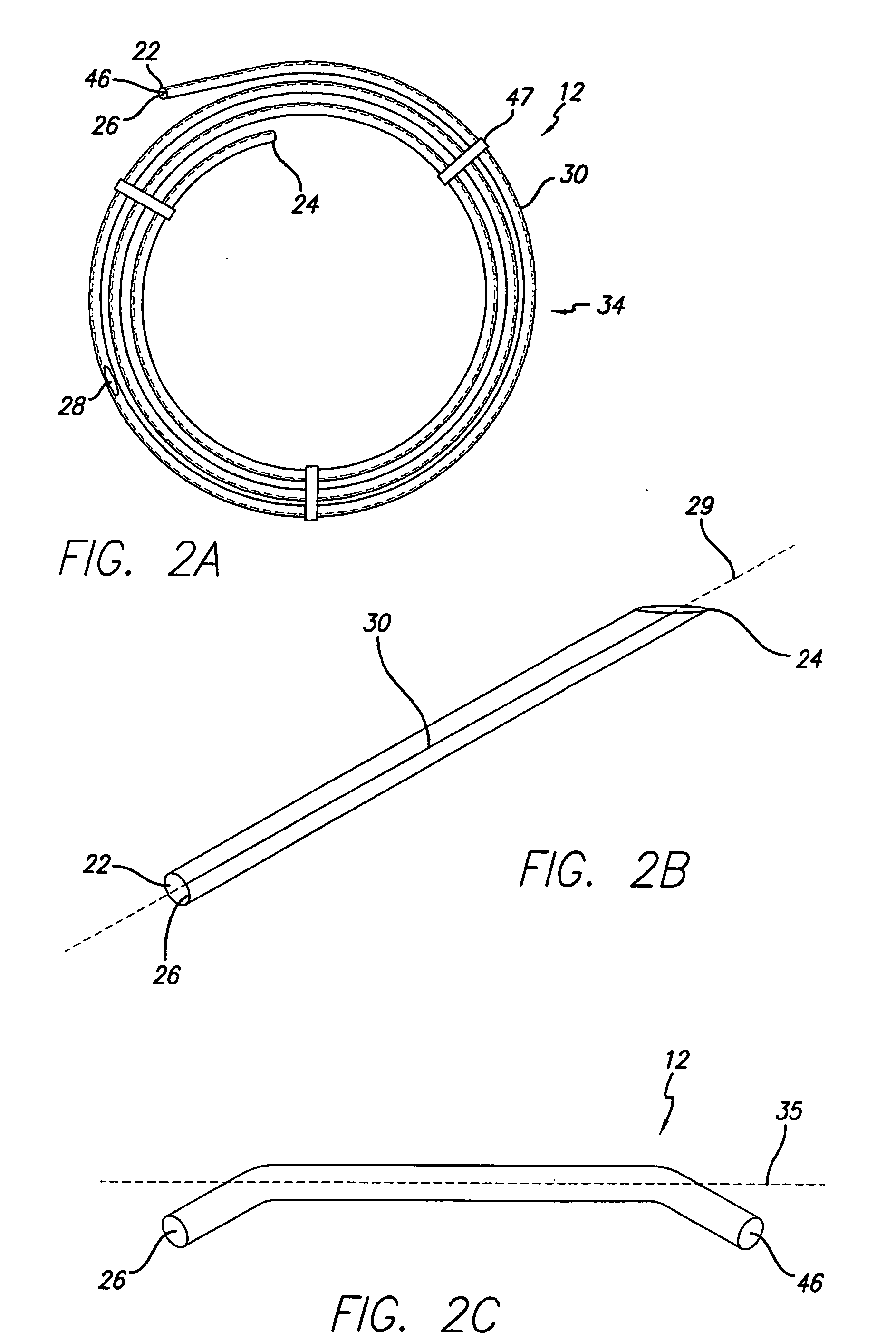

Medical device packaging assembly and method for medical device orientation

ActiveUS7640714B2Prevent radial rotationDispensing apparatusPackage sterilisationMedical deviceBiomedical engineering

Methods of packaging a medical device to orient at least a portion of the medical device and a medical device packaging assembly are provided. A method includes providing an elongate holder having a lumen extending through at least a portion of the holder and providing the medical device including an elongate shaft where the shaft includes a first cross-sectional area having a rotational orientation and a second cross-sectional area having a second rotational orientation. The method further includes aligning the first and second areas so that the first and second rotational orientations are aligned along a longitudinal region of the shaft and inserting at least a portion of the medical device into the lumen of the holder Radial rotation of the first area with respect to the second area is substantially prevented.

Owner:COOK MEDICAL TECH LLC

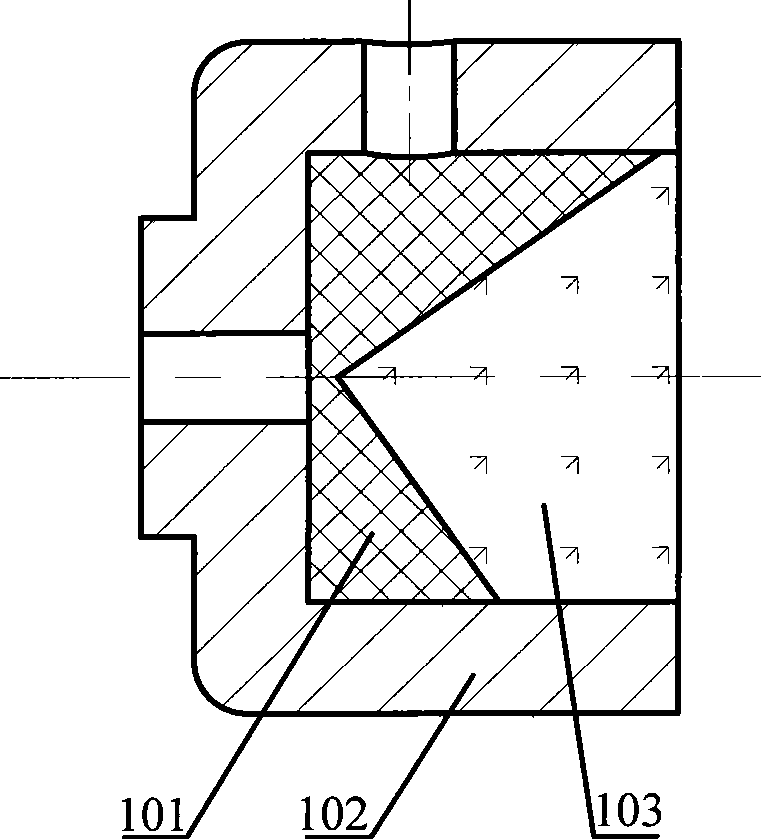

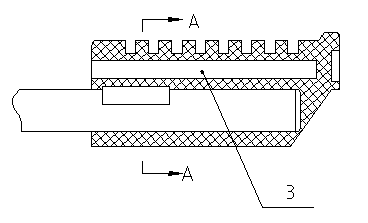

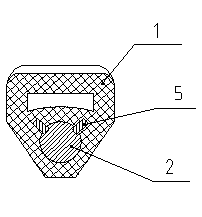

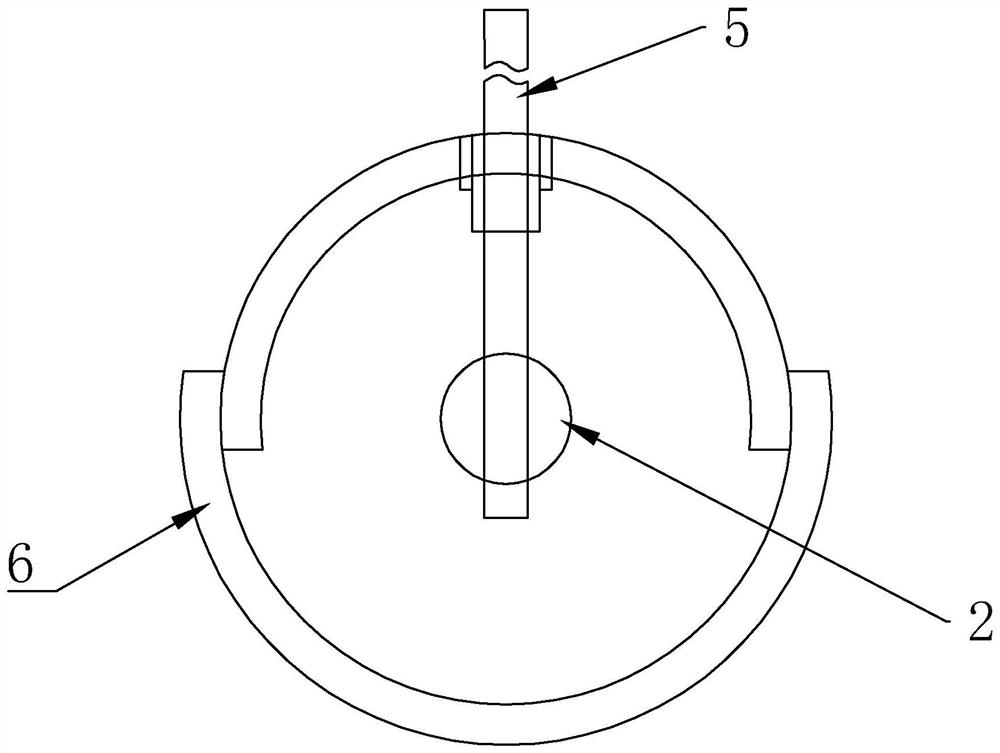

Pyramid prism fixing device and method

The invention discloses a fixing device and a fixing method for a prism of corner cube. The fixing device comprises a clamp, an apron, a base, a lock nut and a holding screw. A hollow hole with a circum-circle diameter less than a bottom diameter of the prism of corner cube is arranged in the clamp and is used for placing the prism of corner cube. A hollow hole with an opening containing inner screw threads is arranged in the base and is used for placing the prism of corner cube and the clamp. The inner hole diameter of the lock nut is slightly less than the circum-circle diameter at the bottom of the prism of corner cube. The gap between the whole length of the hollow hole of the base and the length of the assembled prism of corner cube and clamp is less than the inner screw thread length of the base. The lock nut matches with the base through the inner and exterior screw threads and tightly locks the prism of corner cube in axial direction. The holding screw is screwed in the screw holes in the exterior wall of the base to tightly hold the clamp and prevent the clamp from rotating in the axial direction. The fixing device and a fixing method fully make use of the three orthogonal seamed edges of the prism of corner cube, adopts the three contact styles containing point contact, line contact and surface contact to realize the precisely-fixed prism of corner cube, and has the advantages of simple structure, convenient installation and detachable installation.

Owner:王利强 +1

Medical device packaging assembly and method for medical device orientation

ActiveUS20090288368A1Prevent radial rotationDispensing apparatusPackage sterilisationMedical deviceBiomedical engineering

Methods of packaging a medical device to orient at least a portion of the medical device and a medical device packaging assembly are provided. A method includes providing an elongate holder having a lumen extending through at least a portion of the holder and providing the medical device including an elongate shaft where the shaft includes a first cross-sectional area having a rotational orientation and a second cross-sectional area having a second rotational orientation. The method further includes aligning the first and second areas so that the first and second rotational orientations are aligned along a longitudinal region of the shaft and inserting at least a portion of the medical device into the lumen of the holder Radial rotation of the first area with respect to the second area is substantially prevented.

Owner:COOK MEDICAL TECH LLC

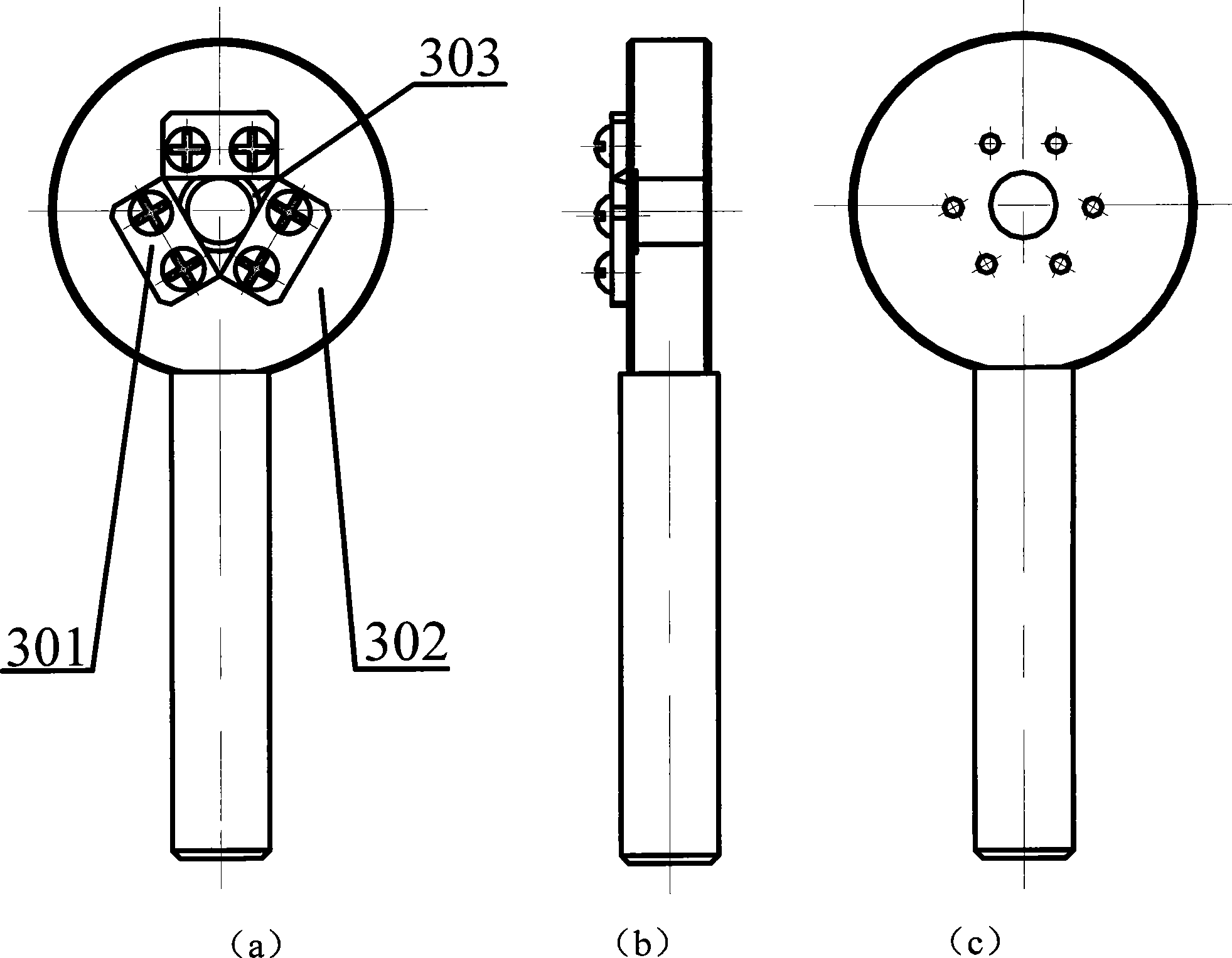

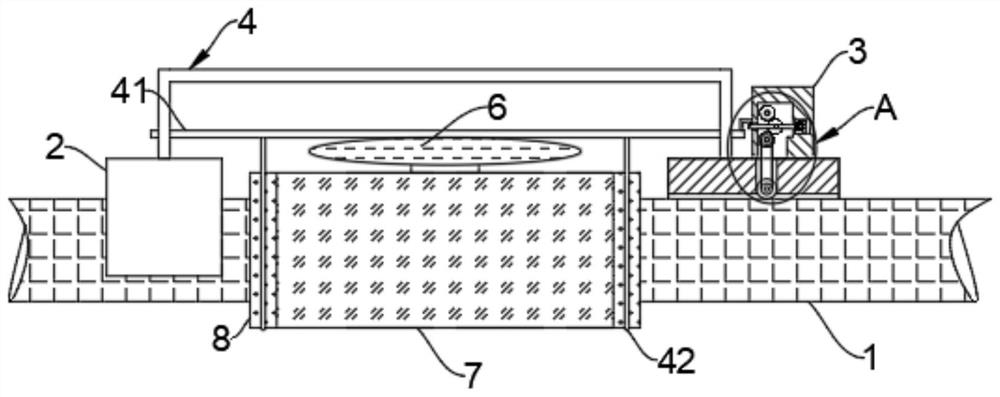

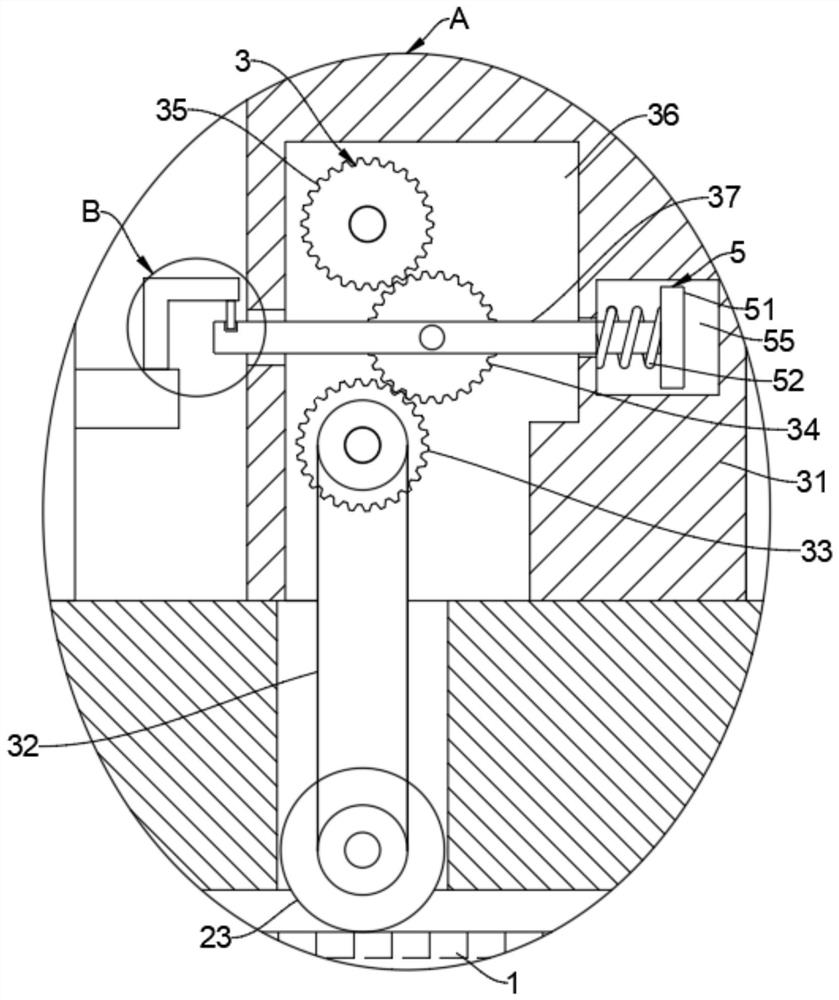

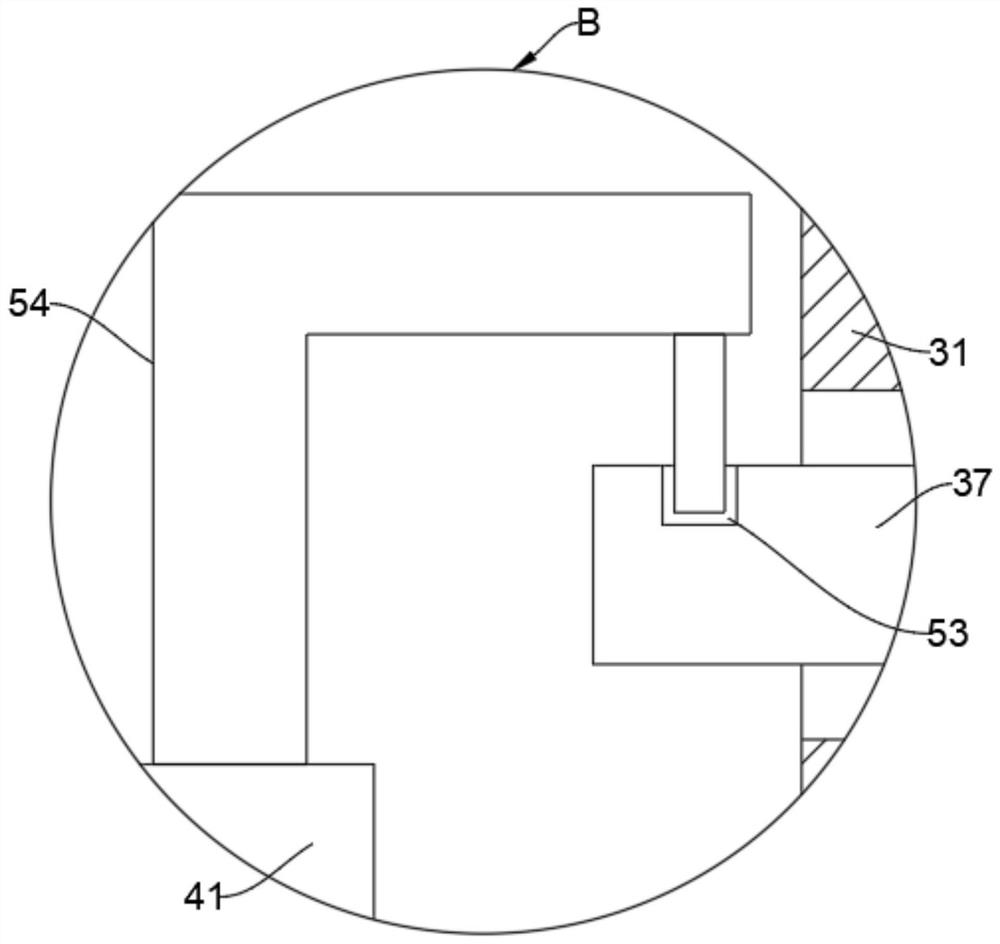

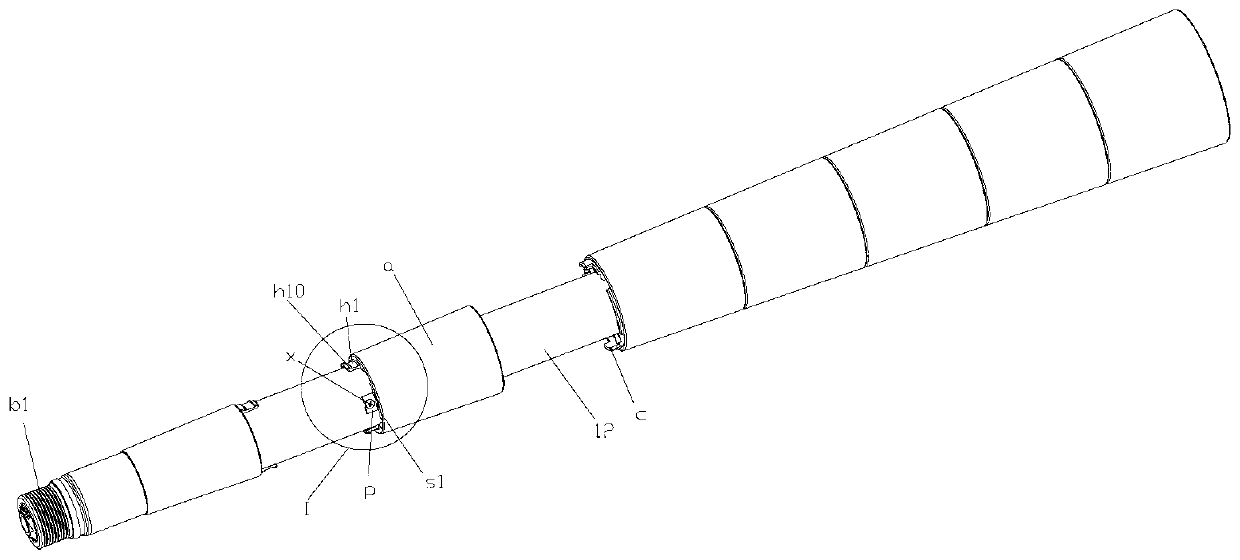

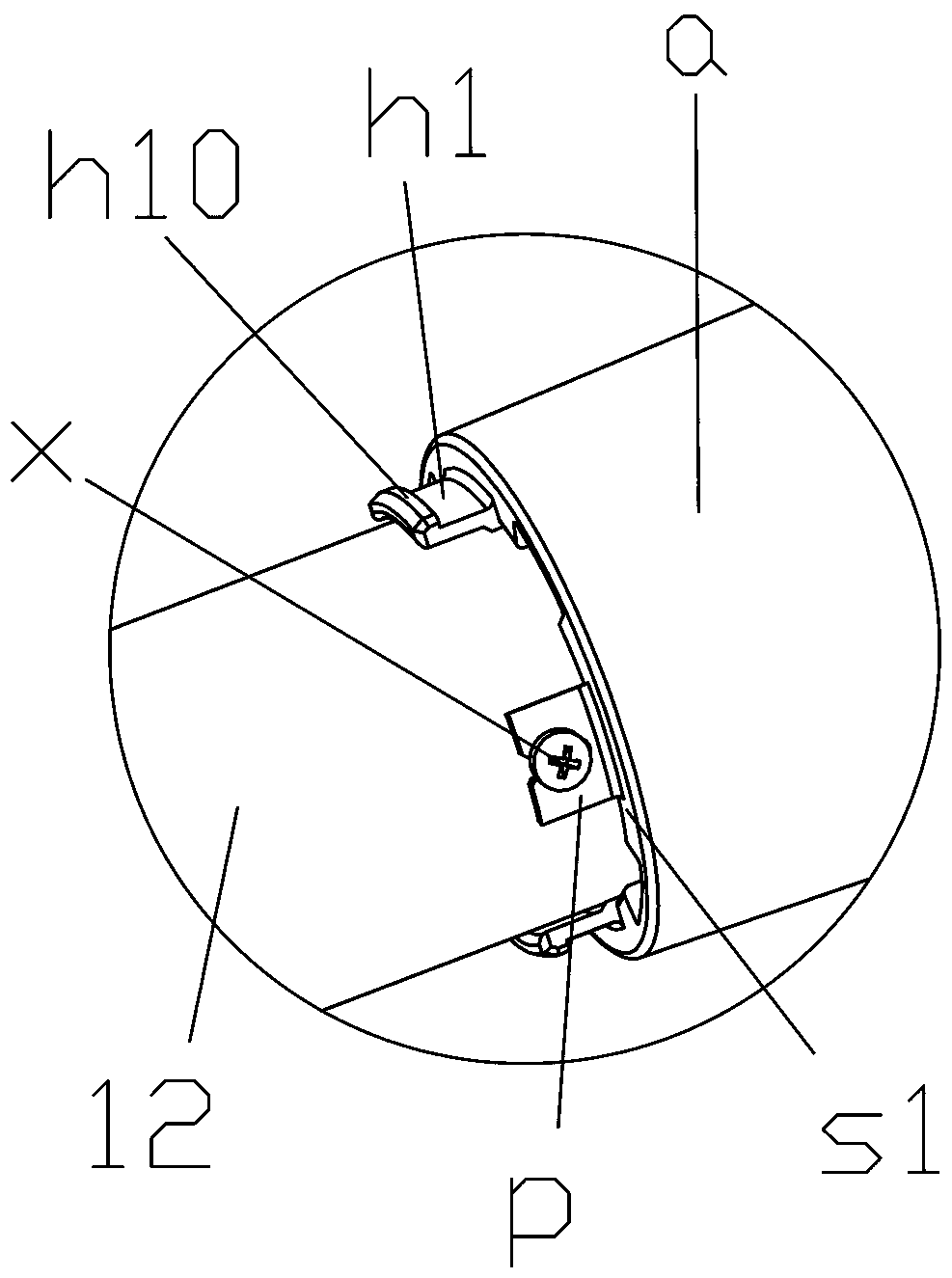

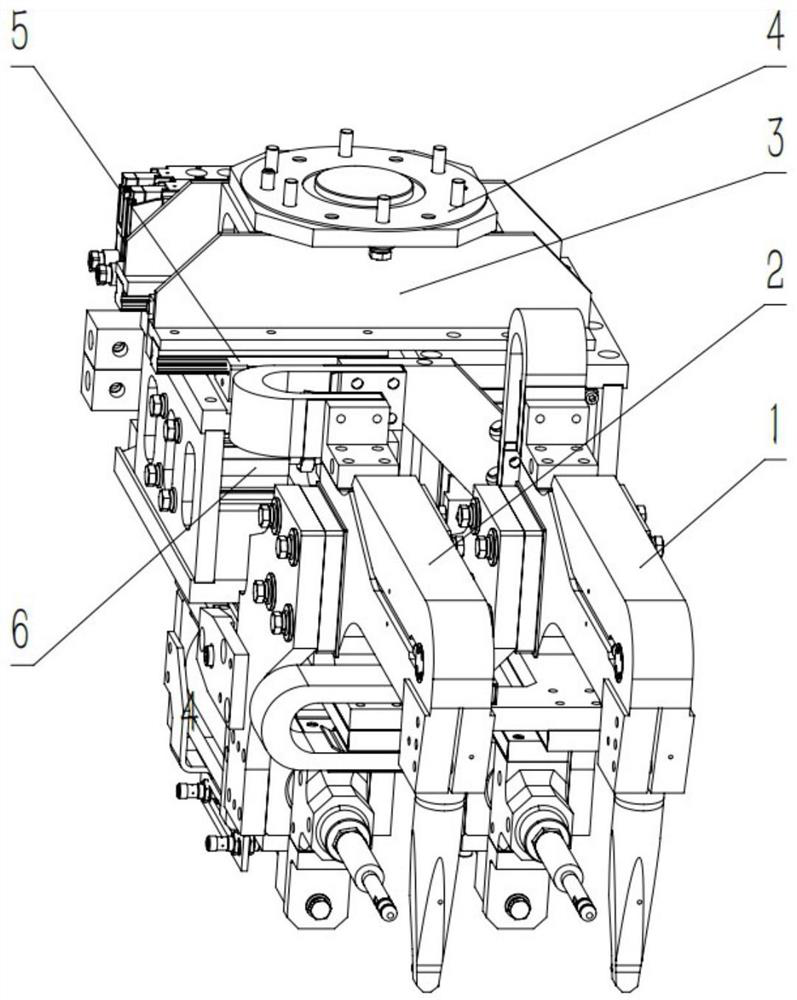

Underwater natural gas pipeline leakage automatic plugging robot and using method thereof

ActiveCN111795253APlay a limiting rolePrevent radial rotationPipe elementsManipulatorClassical mechanicsMechanical engineering

The invention belongs to the field of natural gas transportation, and particularly relates to an underwater natural gas pipeline leakage automatic plugging robot and a using method thereof. The underwater natural gas pipeline leakage automatic plugging robot comprises two supporting mechanisms connected with a pipeline, one of the supporting mechanisms is provided with a driving mechanism, a connecting piece is fixedly connected between the two supporting mechanisms, sliding rods are connected to the two ends of the connecting piece in a sliding mode, and limiting mechanisms matched with the sliding rods are arranged on the driving mechanisms. By arranging a supporting cylinder, a protective film, a stretching, an air bag and other structures, when the device has a pipeline gas leakage position, gas can penetrate through the supporting cylinder to enter the air bag to enable the air bag to expand, the air bag expands to drive the sliding rods to move upwards, then the sliding rods pullthe pull rope, the protective film is tensioned by stretching, so that the protective film is tightly attached to the outer side of the pipeline, the two ends of the gas leakage position of the pipeline are blocked by the protective film, and then the gas leakage position of the pipeline is blocked in the supporting cylinder.

Owner:重庆创御智能装备有限公司

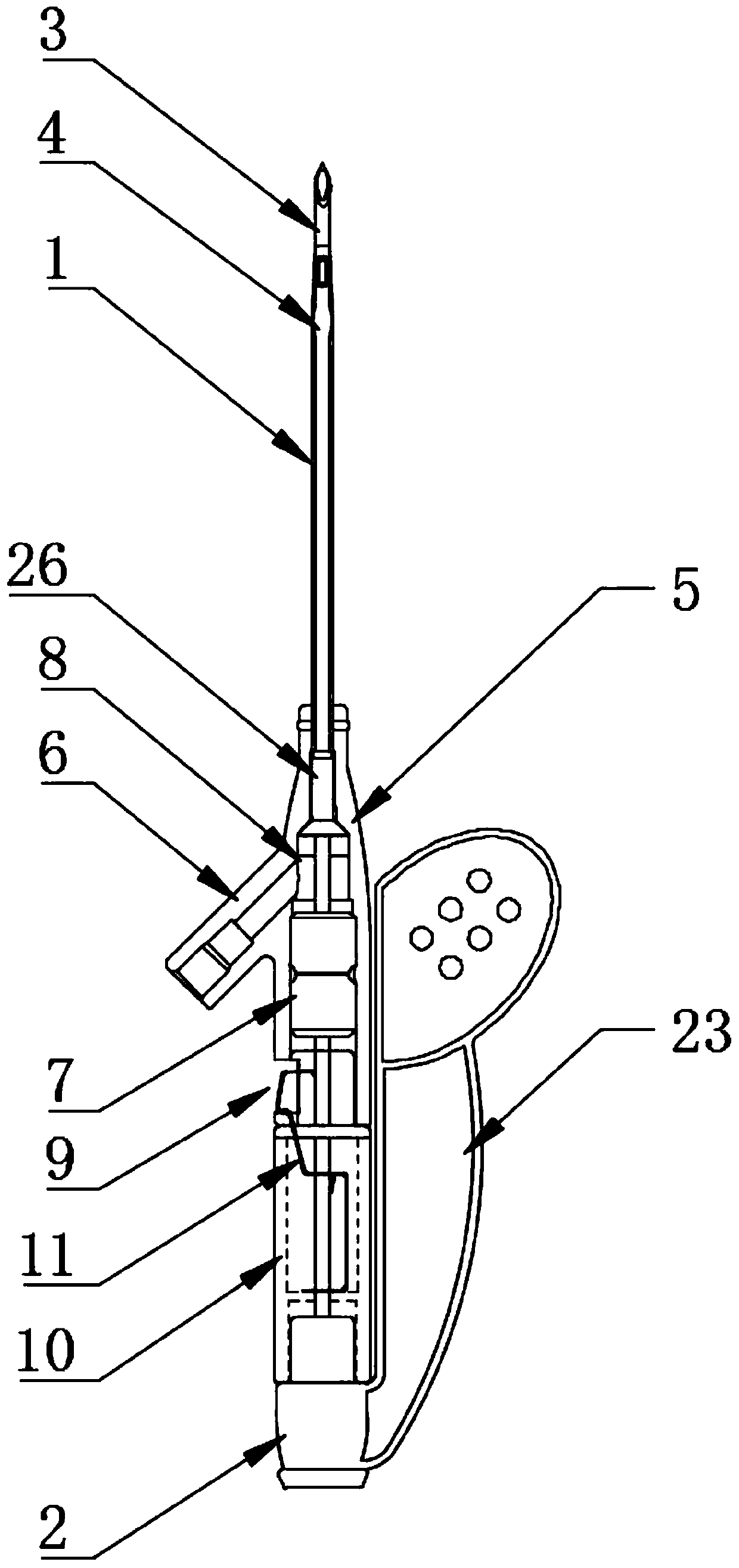

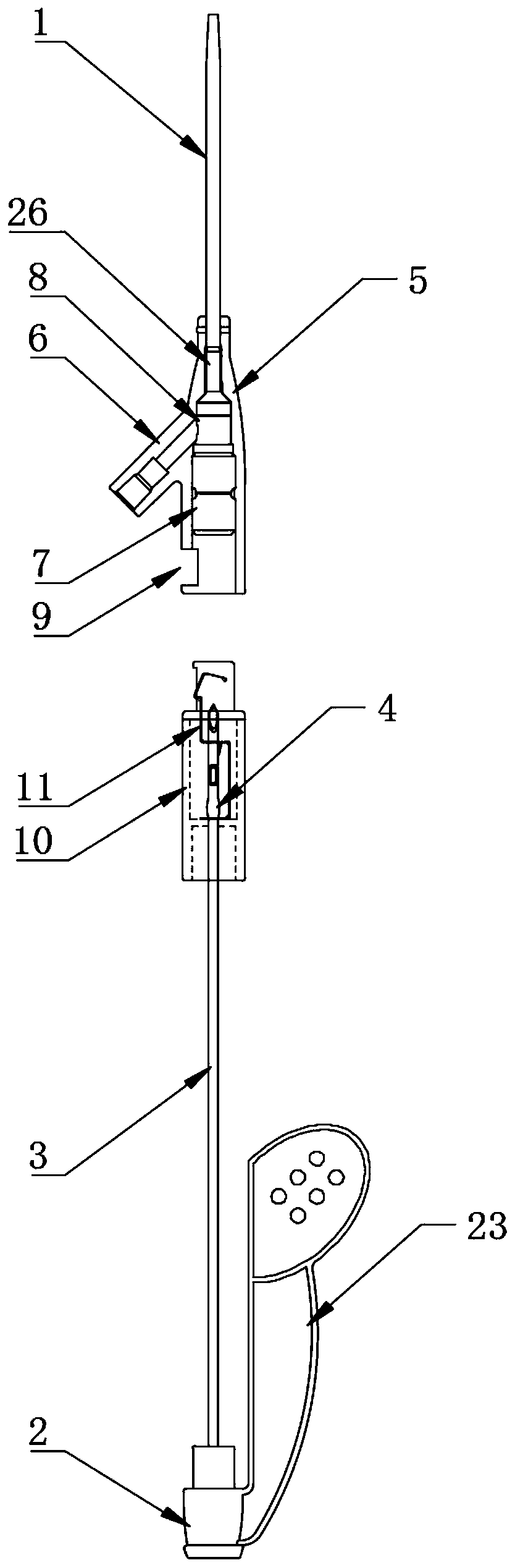

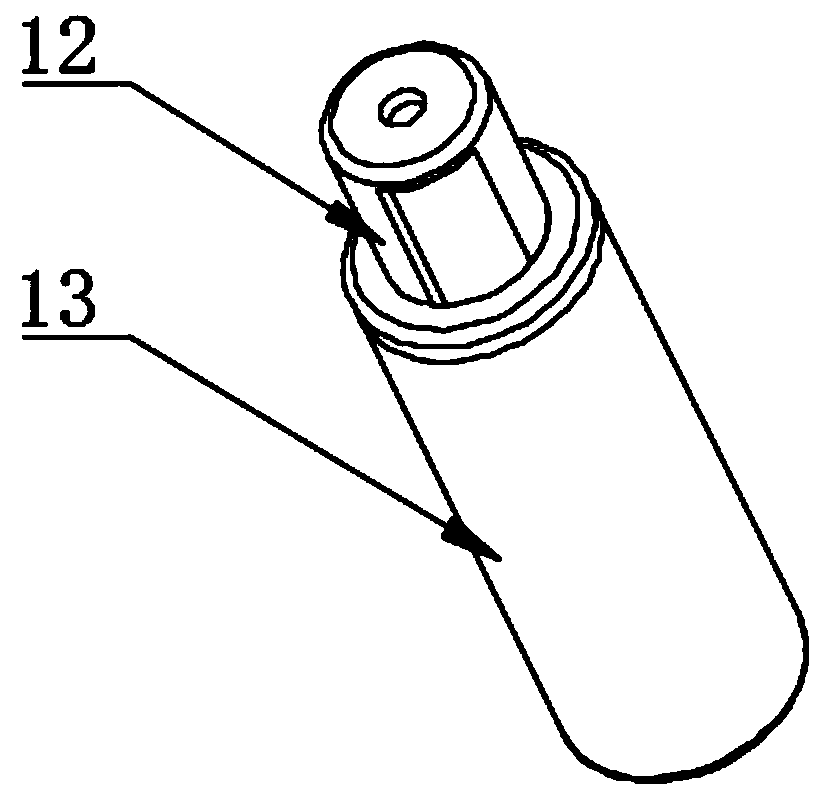

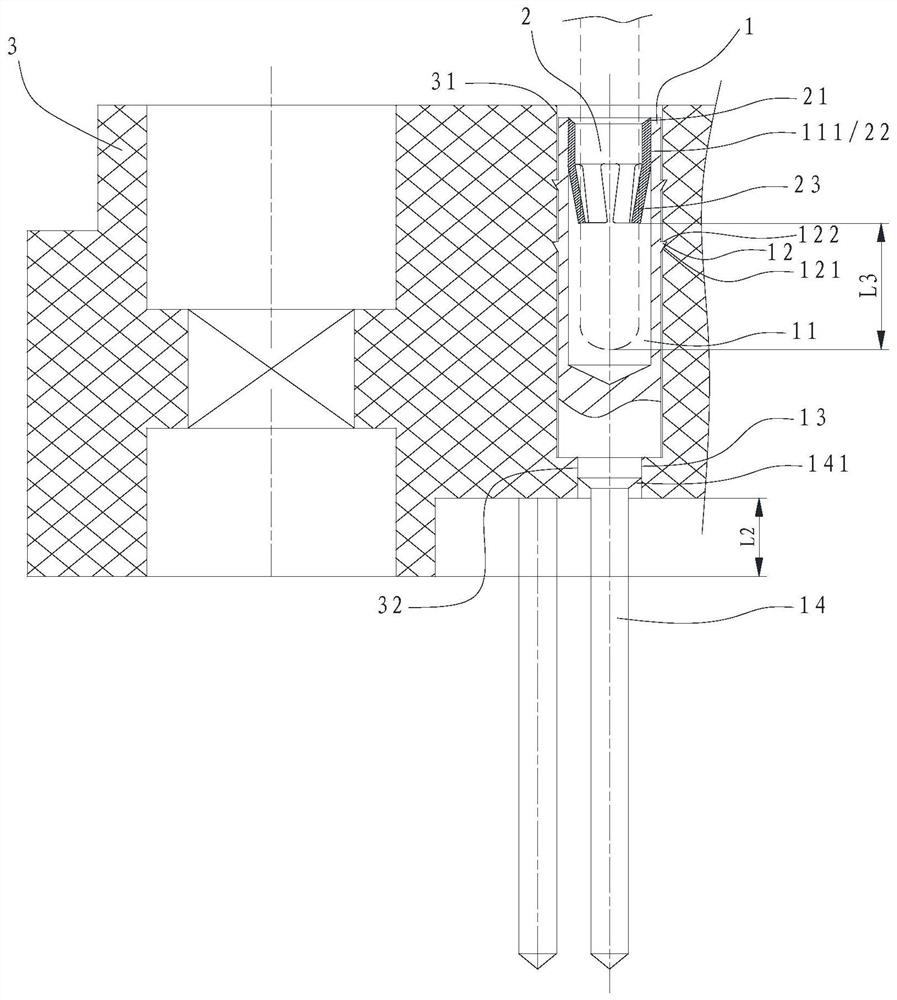

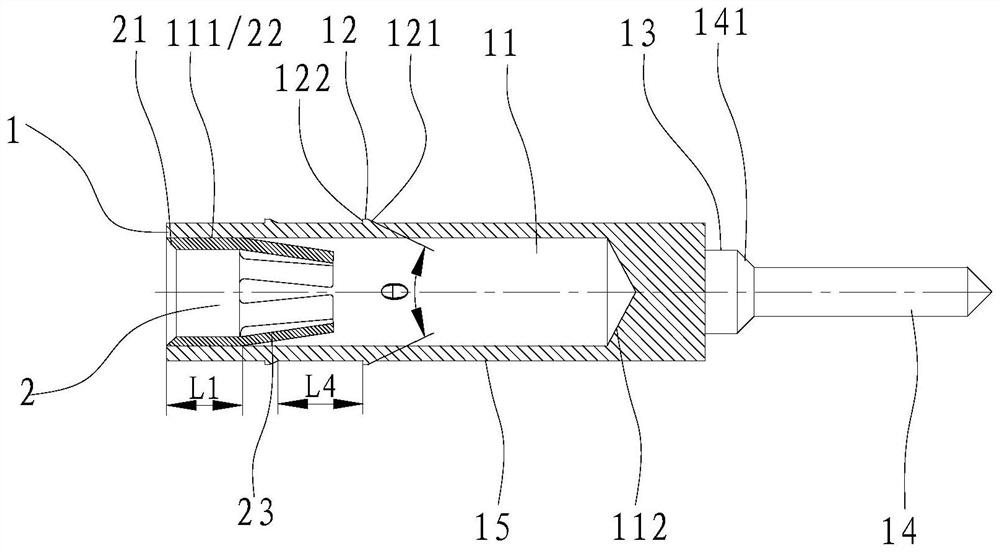

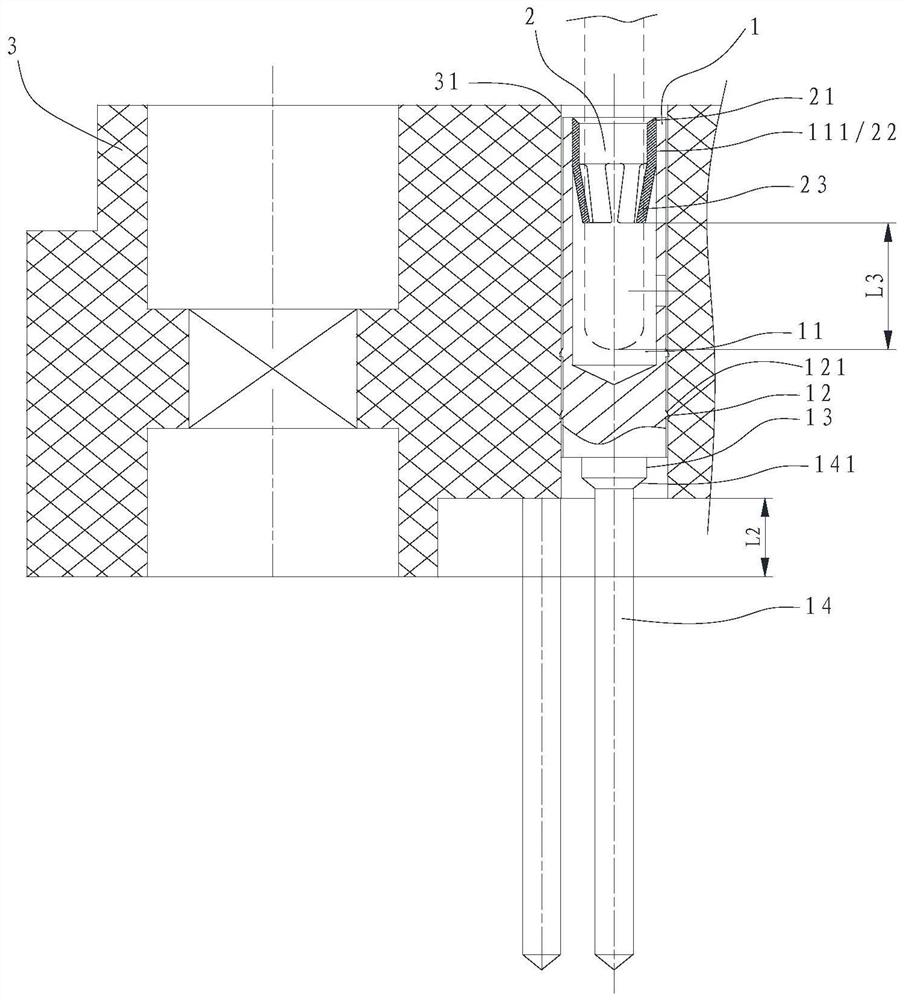

Anti-puncture remaining needle assembly

The invention provides an anti-puncture remaining needle assembly and belongs to the field of medical apparatus and instruments. The assembly comprises a puncture assembly, a hose holder, a hose and an anti-puncture assembly; a bulge with outer diameter larger than that of a steel needle is formed on the steel needle, and a notch is formed in the side edge of the hose holder; an elastic piece baseis a tubular base provided with an opening in the bottom, an elastic piece groove in the side part and an elastic piece baffle at the top, a partition is fixedly mounted in a sleeve, and steel needlepassing holes with outer diameter larger than outer diameter of the bulge are formed in the elastic piece baffle and the partition; a propping piece propped against the outer wall of the steel needleis fixed on an anti-puncture elastic piece, and the steel needle is enabled to lean against the inner side of the anti-puncture elastic piece; the elastic piece base is sleeved with the sleeve, and the anti-puncture elastic piece is mounted in the elastic piece groove and the sleeve; the elastic piece base is inserted into the hose holder, and the anti-puncture elastic piece bulges out of the elastic piece groove and is clamped at the notch in a hanging manner. The anti-puncture remaining needle assembly which can be used for storing and protecting the steel needle during needle withdrawal issimple in structure, convenient to mount and good in anti-puncture effect.

Owner:JIANGSU SUYUN MEDICAL MATERIALS

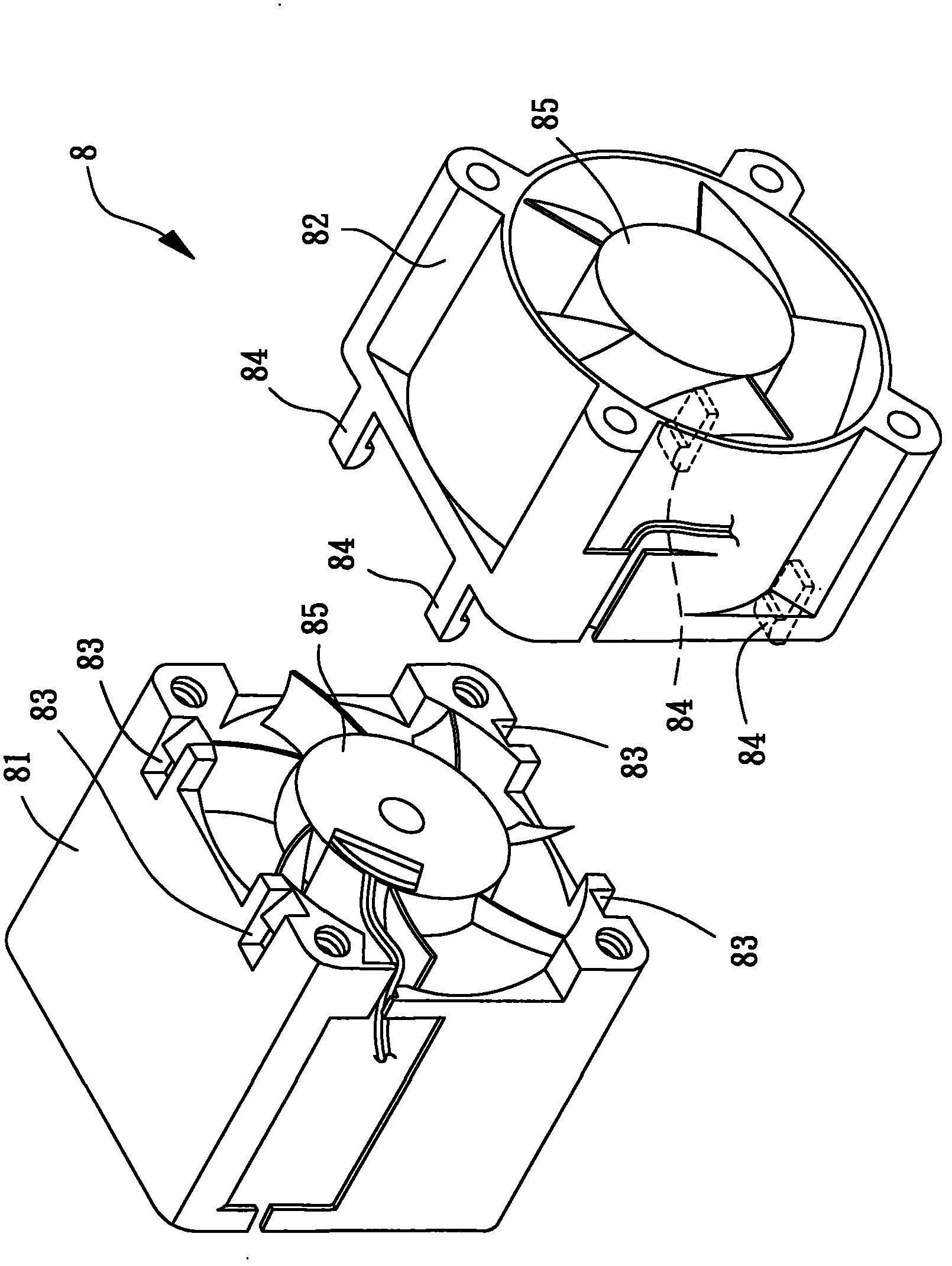

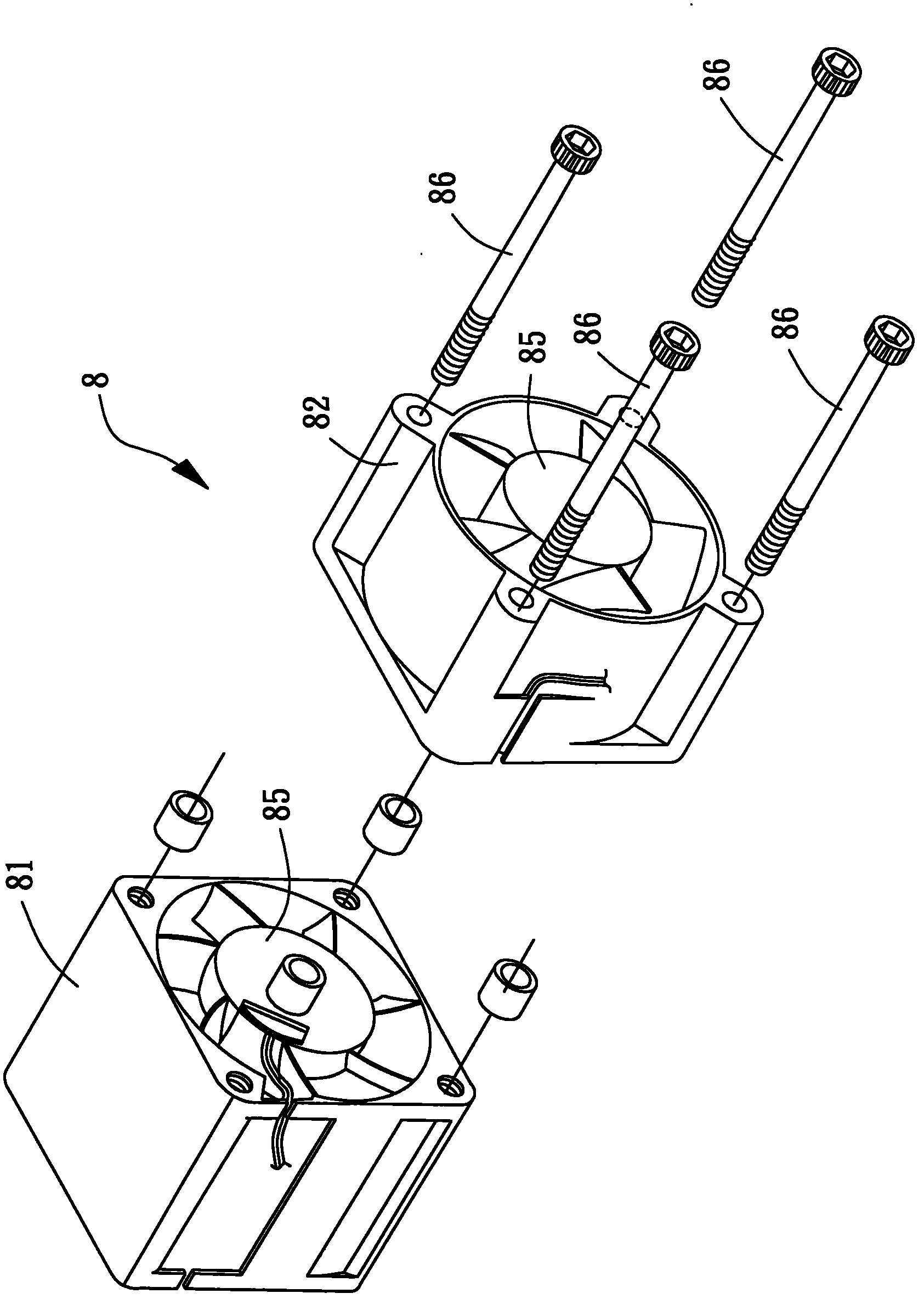

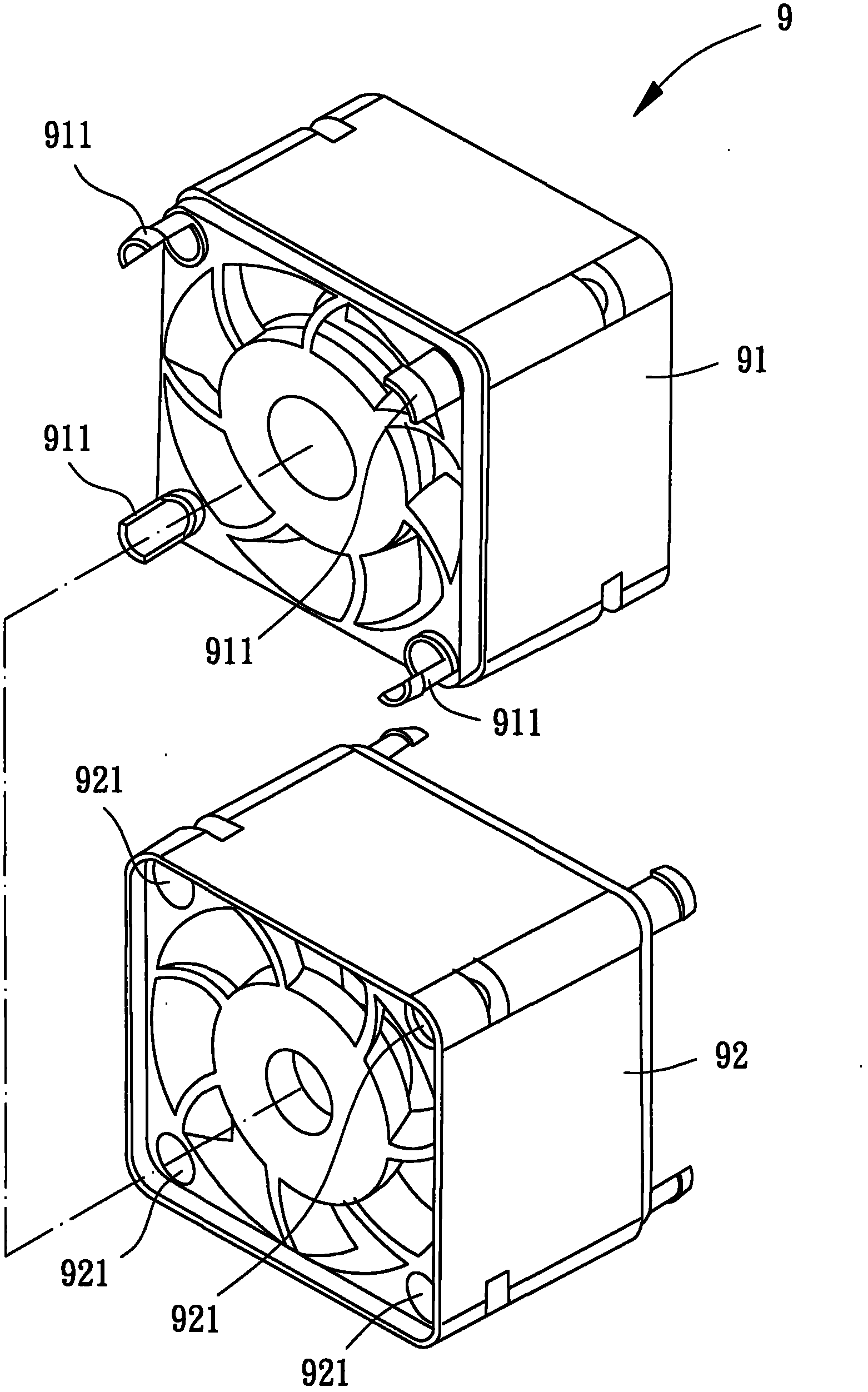

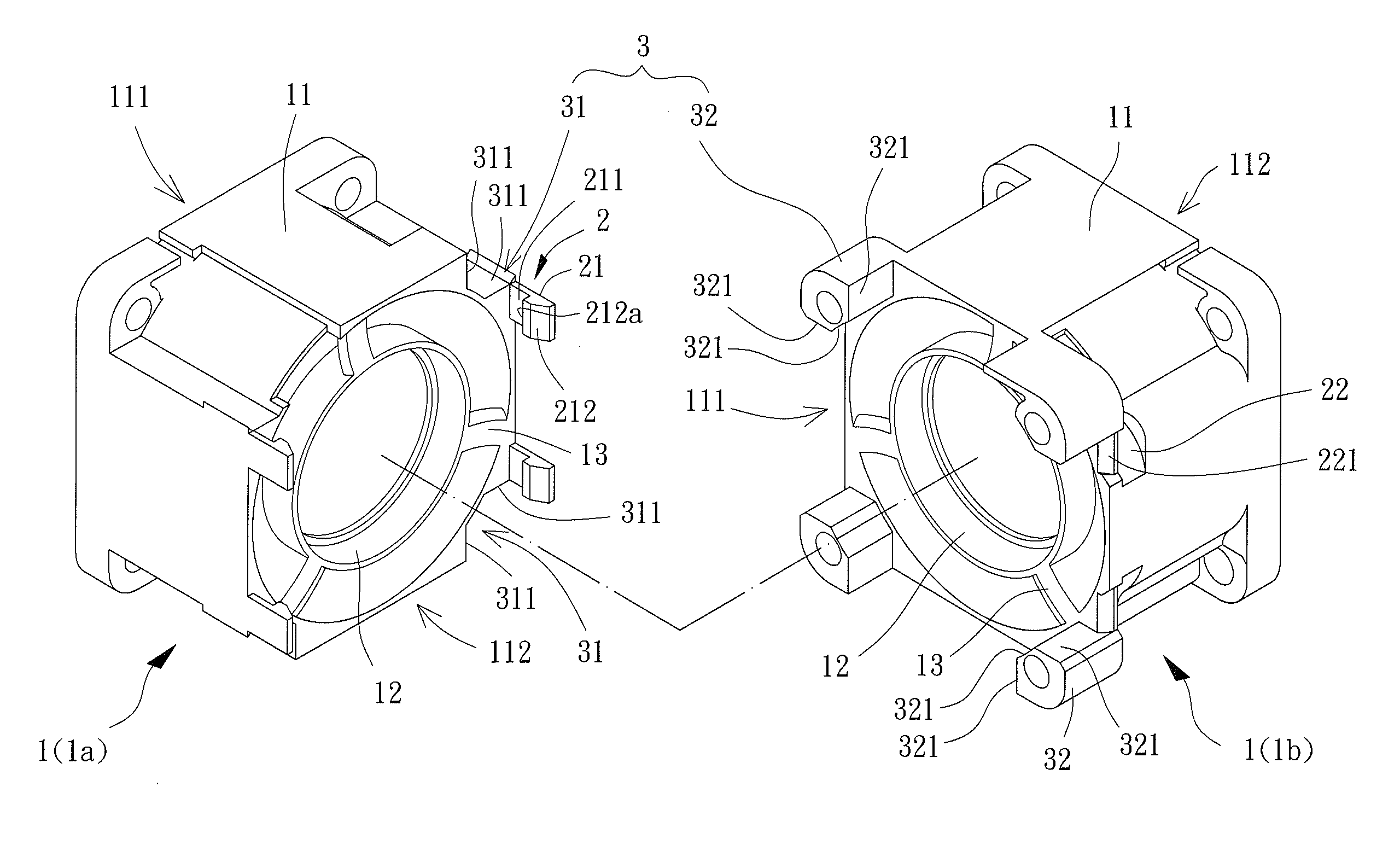

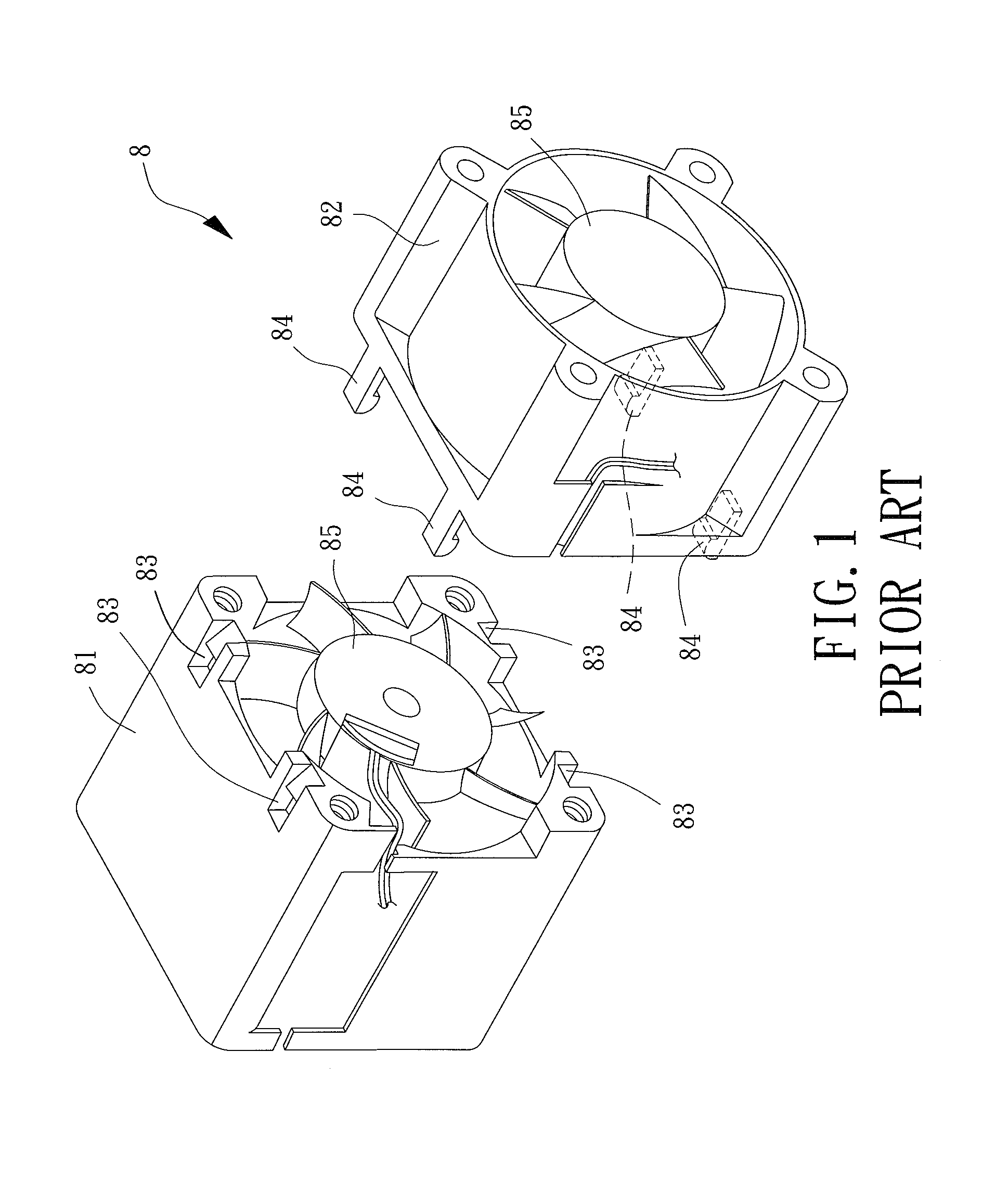

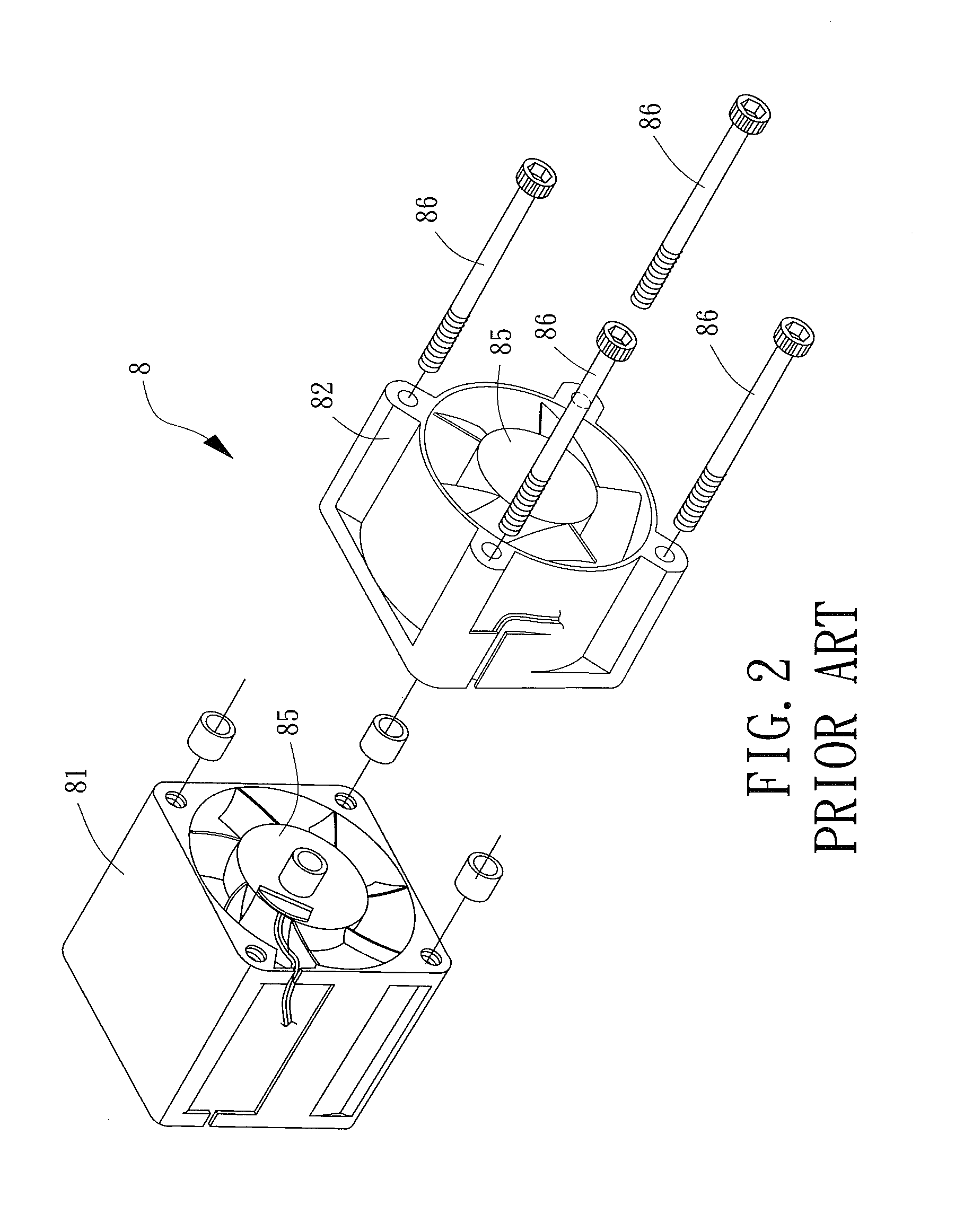

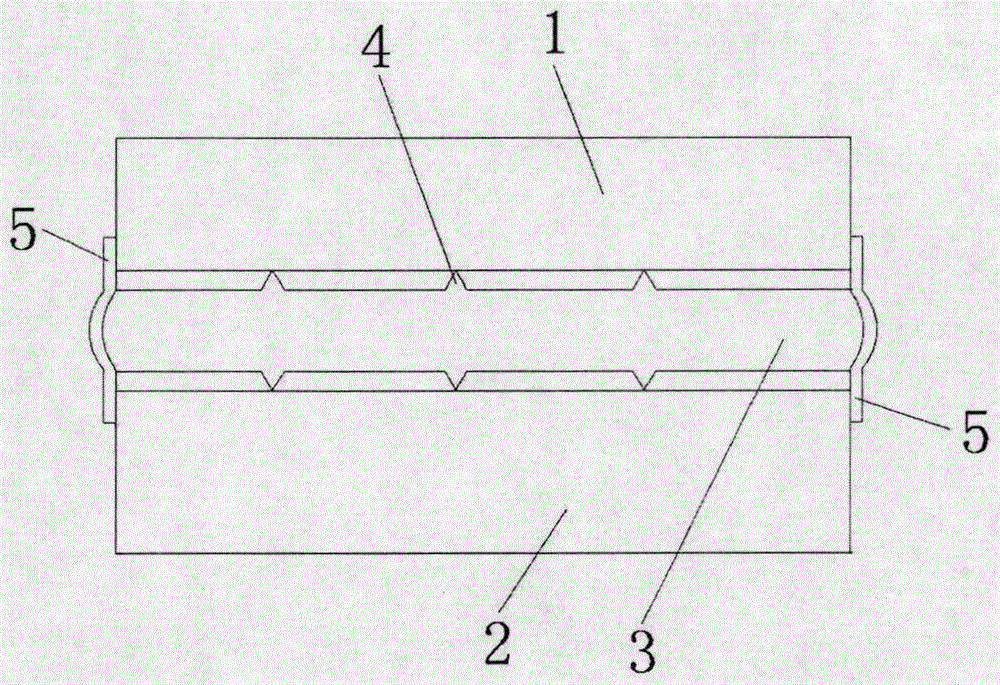

Tandem fan frame module

The invention discloses a tandem fan frame module. The tandem fan frame module comprises a plurality of fan frames, a tandem buckle assembly and a radial auxiliary anti-rotating assembly, wherein the plurality of fan frames are arranged in series; the tandem buckle assembly is arranged in each fan frame and combining the fan frames; and the radial auxiliary anti-rotating assembly is arranged in each fan frame and comprises at least one limiting piece and at least one stopping piece, wherein the limiting piece and the stopping piece are respectively arranged on the jointed part of the two adjacent fan frames, and the limiting piece is propped against the stopping piece. Therefore, by matching the radial auxiliary anti-rotating assembly, the radial anti-rotating function of each fan frame is enhanced, and the integral structural strength is further promoted.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

Series-connected fan frame module

ActiveUS8684688B2Improve structural strengthPrevent radial rotationPropellersPump componentsEngineeringPosition fixing

A series-connected fan frame module includes a plurality of frames, an engaging assembly and an anti-rotation assembly. The frames are arranged in series. The engaging assembly is arranged on each of the frames to couple the frames in series. The anti-rotation assembly is arranged on each of the frames and includes at least one position-fixing member and at least one blocking member arranged on portions of adjacent two of the frames where the adjacent two of the frames are coupled together. The at least one position-fixing member is engaged with the at least one blocking member to prevent relative radial rotation between the adjacent two of the frames.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

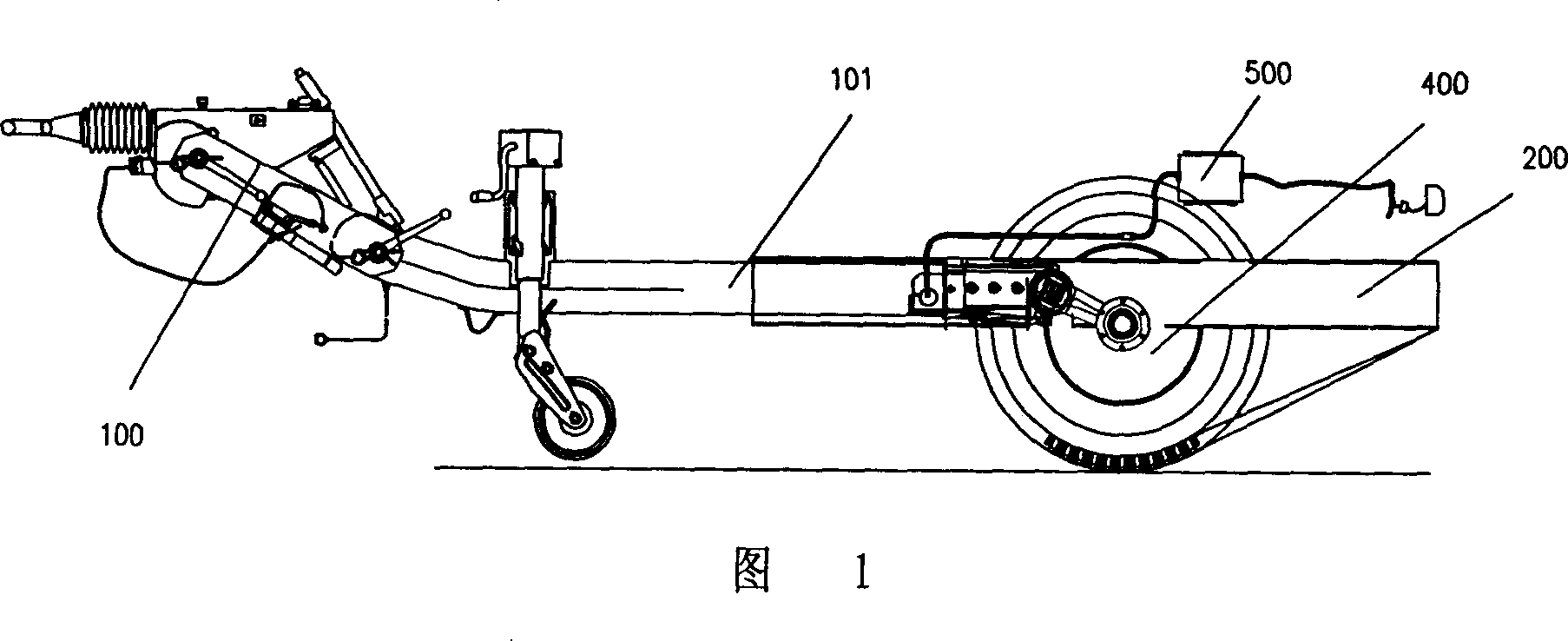

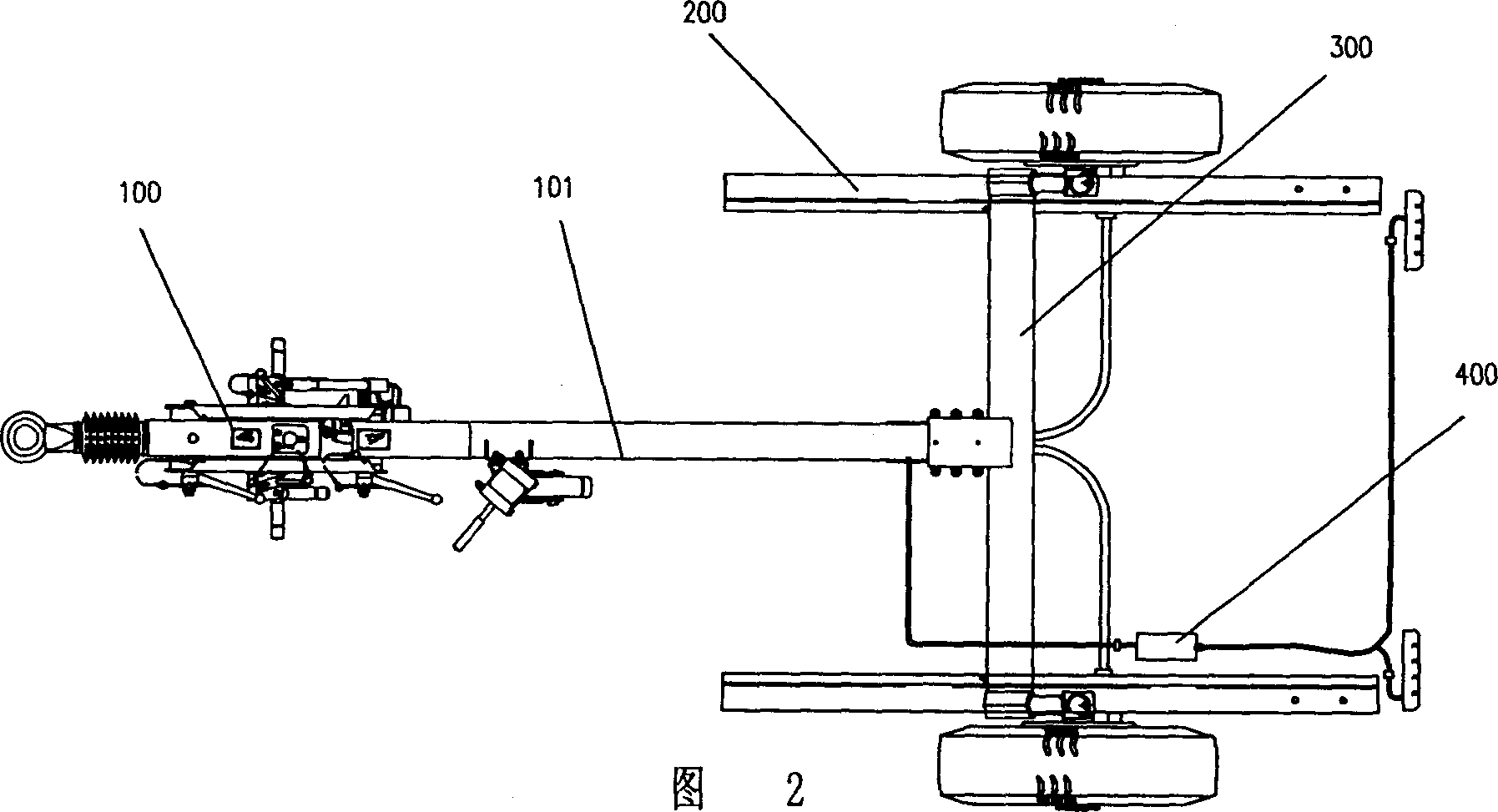

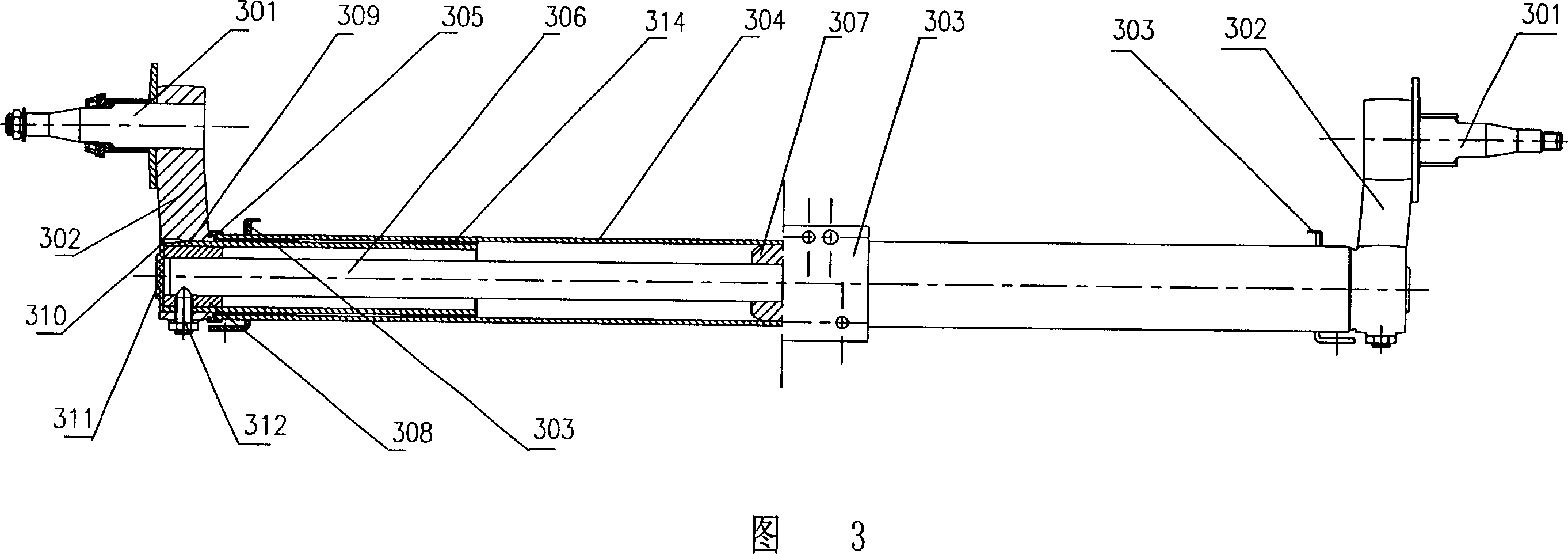

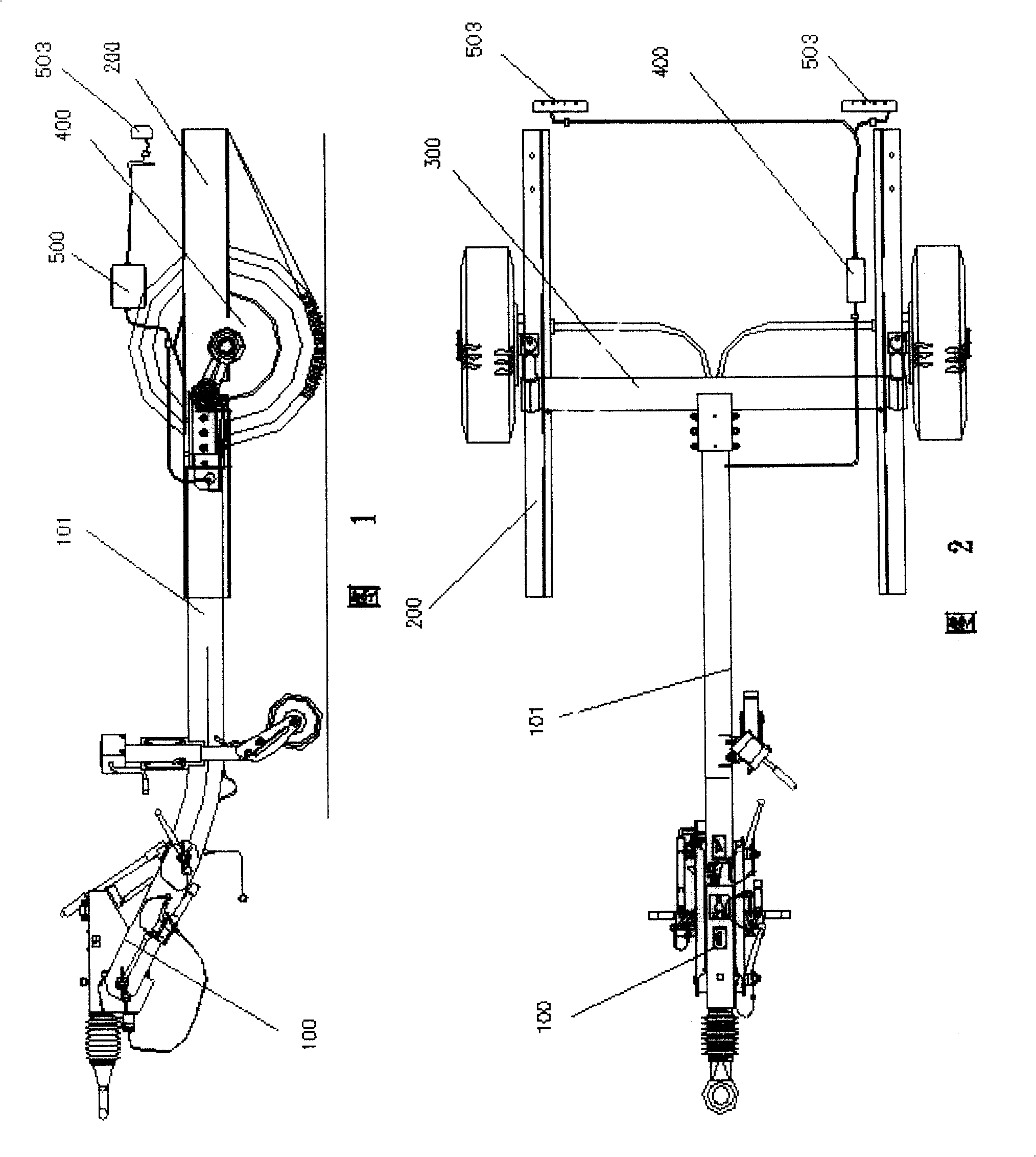

Trailer

InactiveCN1974302AFirmly connectedPrevent axial movementOptical signallingDrum brakesEngineeringBrake shoe

The trailer includes mainly one hauling machine, one auxiliary frame, one suspension device, one braking device and one tail lamp system. It features the suspension device with one nearly square torsion piece combination comprising elastic steel pieces; the braking device with one braking shoe assembly comprising one double layered rocker, two locating pins, one braking shoe plate and one braking friction sheet; the tail lamp system with at least one transition connector connected between one plug and one socket. The trailer has the advantages of capacity of being connected with different kinds of tractor, smooth running, etc.

Owner:北京军适机械有限公司

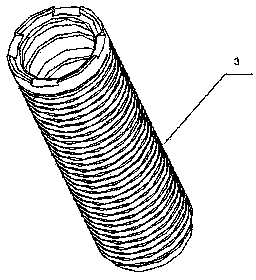

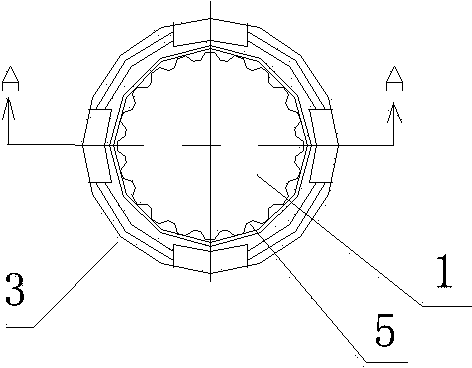

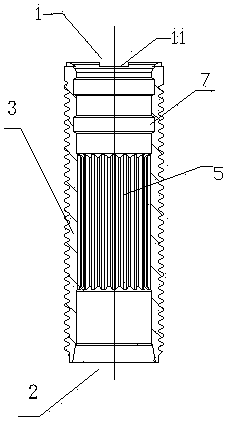

Hydraulic expanding sleeve type tool for gear tooth shape processing

InactiveCN105689813ARaise the swell size limitImprove applicabilityGear-cutting machinesGear teethEngineeringMachine tool

The invention discloses a hydraulic expanding sleeve type tool for gear tooth shape processing. One end of an expanding sleeve positioning basic body is fixed to a machine tool; the other end of the expanding sleeve positioning basic body is fixed to a gear positioning cover; one end, back to the expanding sleeve positioning basic body, of the gear positioning cover is provided with a gear positioning slot; the end part of the expanding sleeve positioning basic body passes through a slot bottom of the gear positioning slot, and is positioned in the gear positioning slot; one end, in the gear positioning slot, of the expanding sleeve positioning basic body is provided with an expanding sleeve in a sleeved manner; the expanding sleeve positioning basic body is fixed to one end of a hydraulic drawbar through a bolt; the other end of the hydraulic drawbar passes through a central through hole of the expanding sleeve positioning basic body, and is fixed to a hydraulic rod; the circumferential surface, which is in contact with the expanding sleeve, of the expanding sleeve positioning basic body is a slope surface A; the position, which corresponds to the slope surface A, of the expanding sleeve is provided with a slot; the slot wall of the slot is matched with the slope surface A; and the contact part of a gear and the expanding sleeve is positioned in the positioning slot. According to the invention, the hydraulic expanding sleeve type tool is used for fixing the gear, so that the gear can smoothly be subjected totooth shape processing.

Owner:江苏双环齿轮有限公司

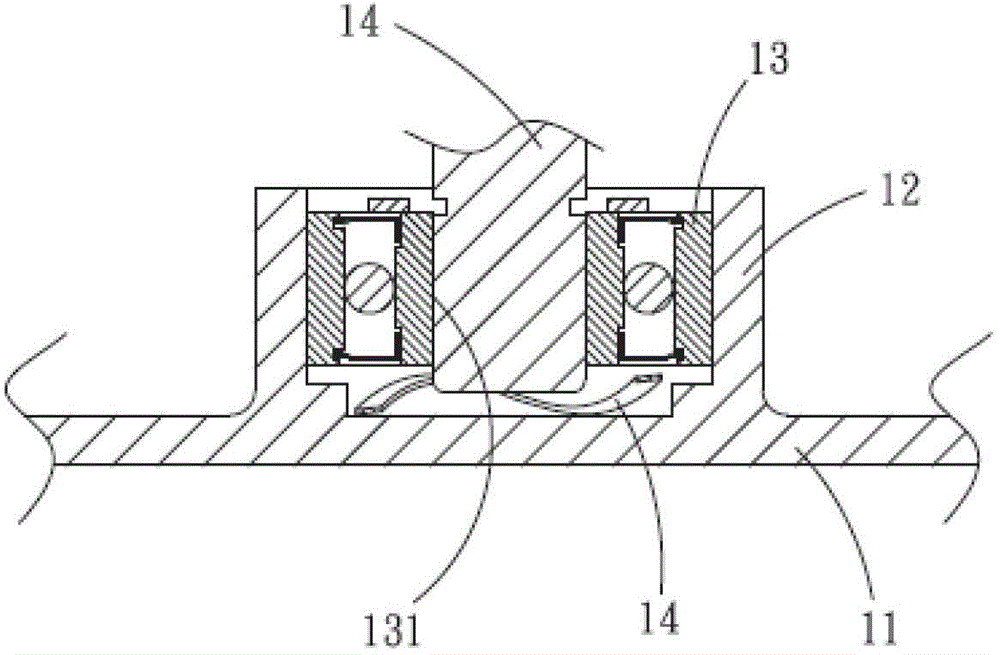

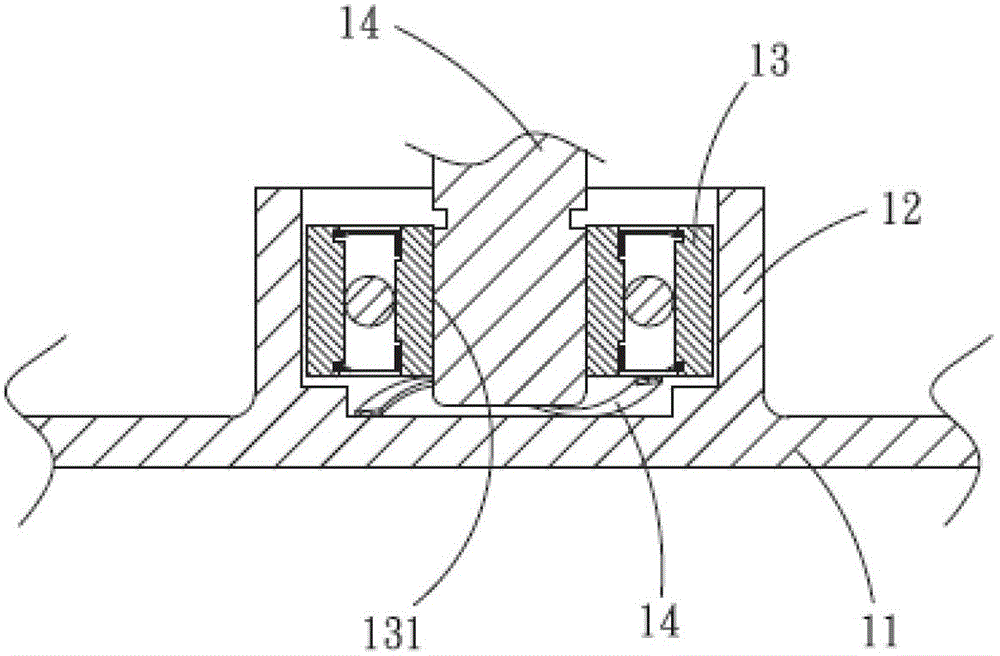

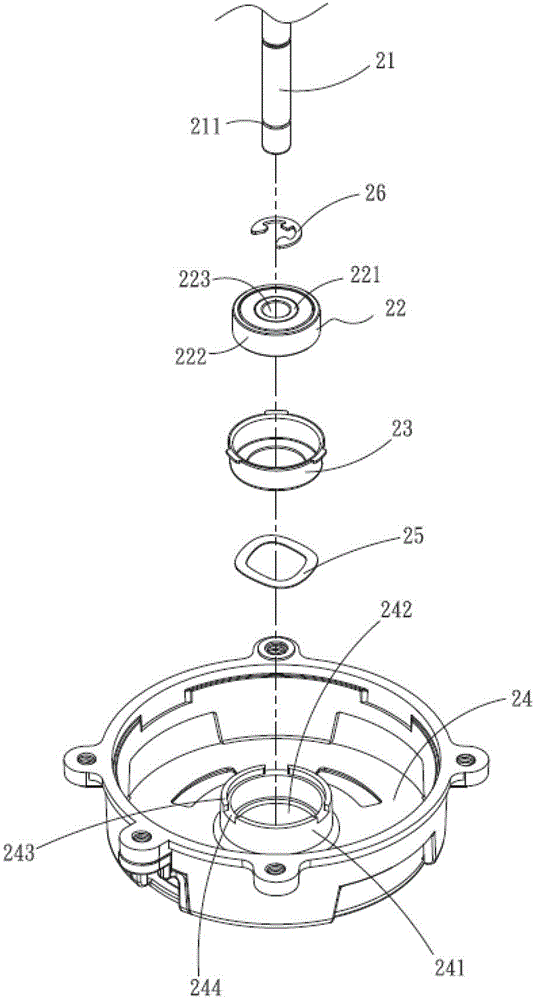

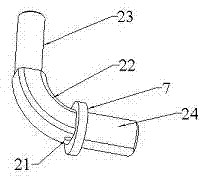

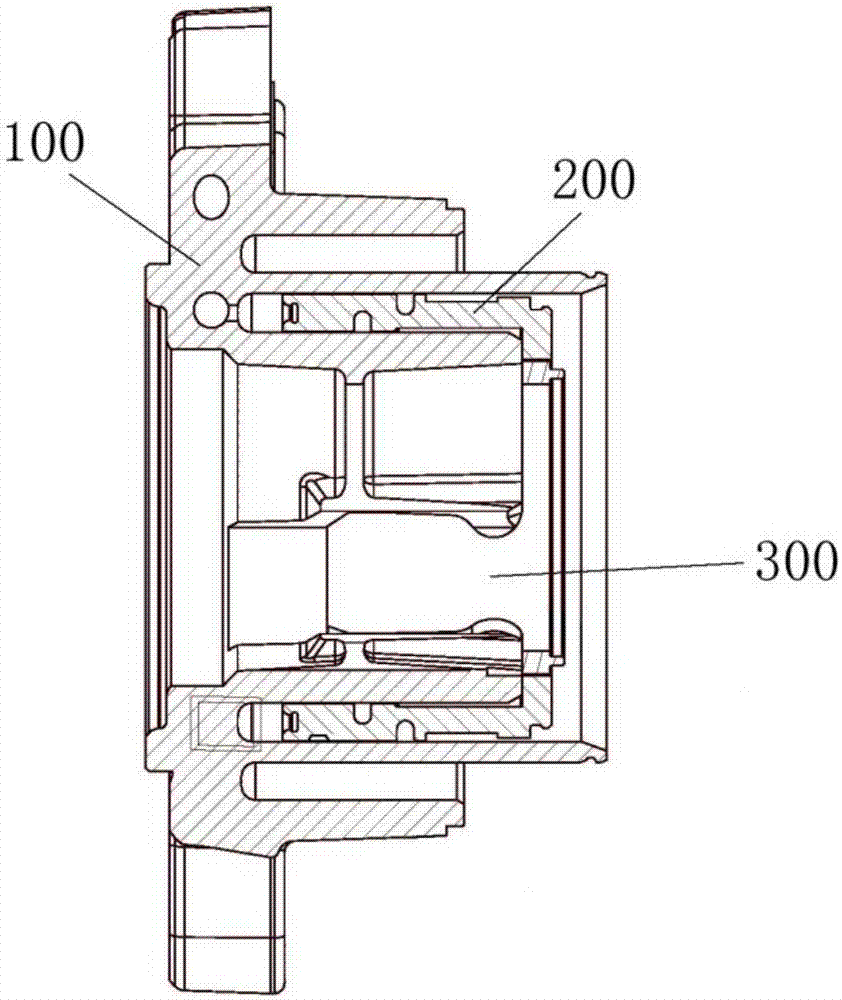

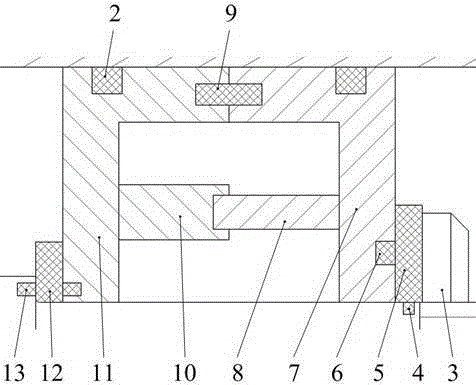

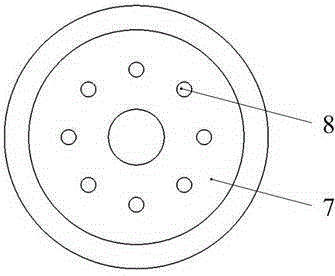

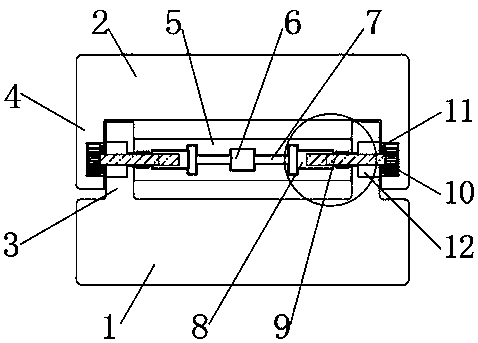

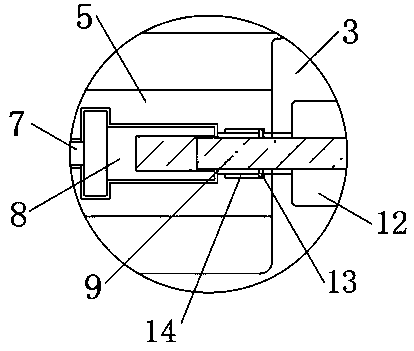

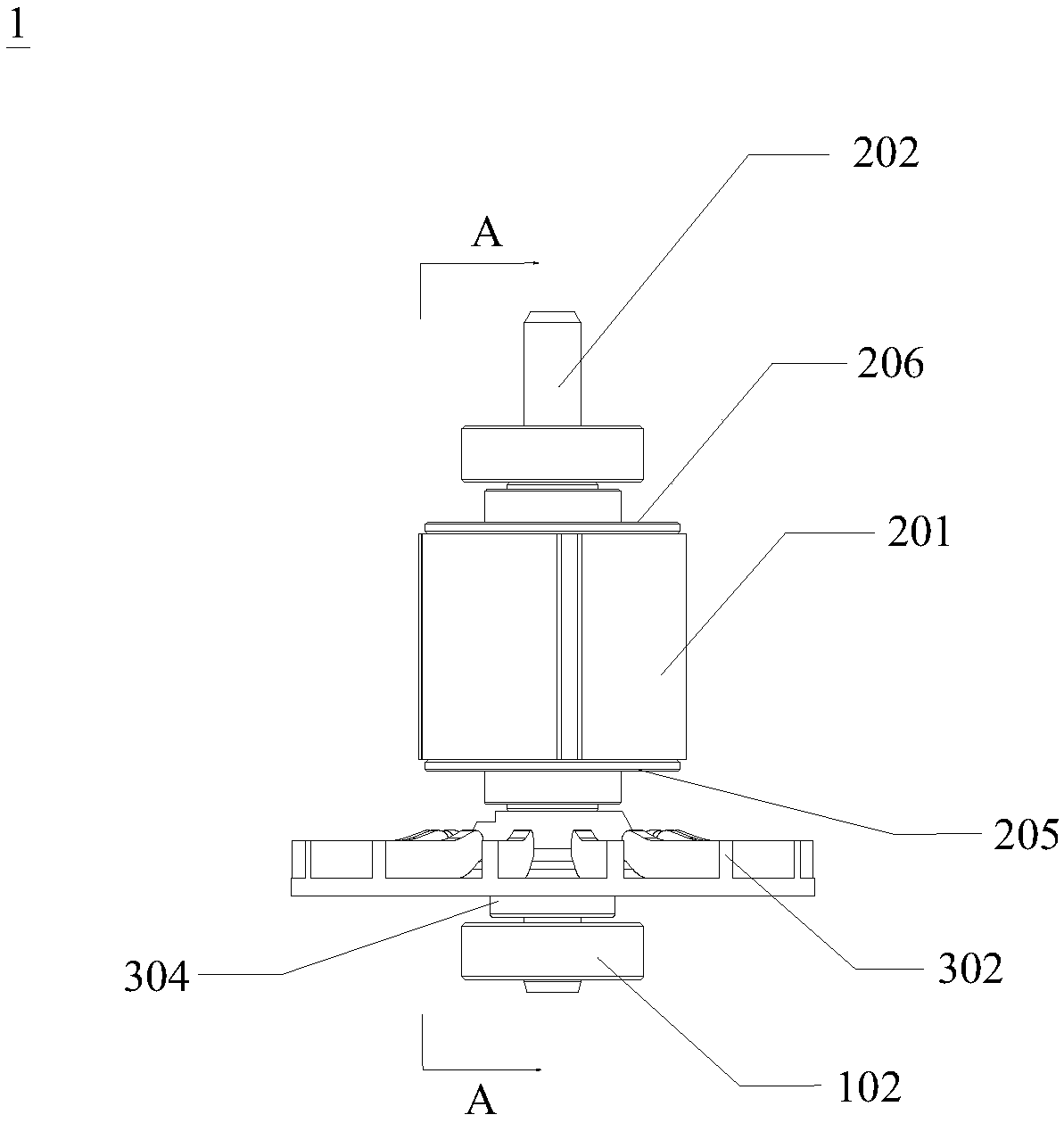

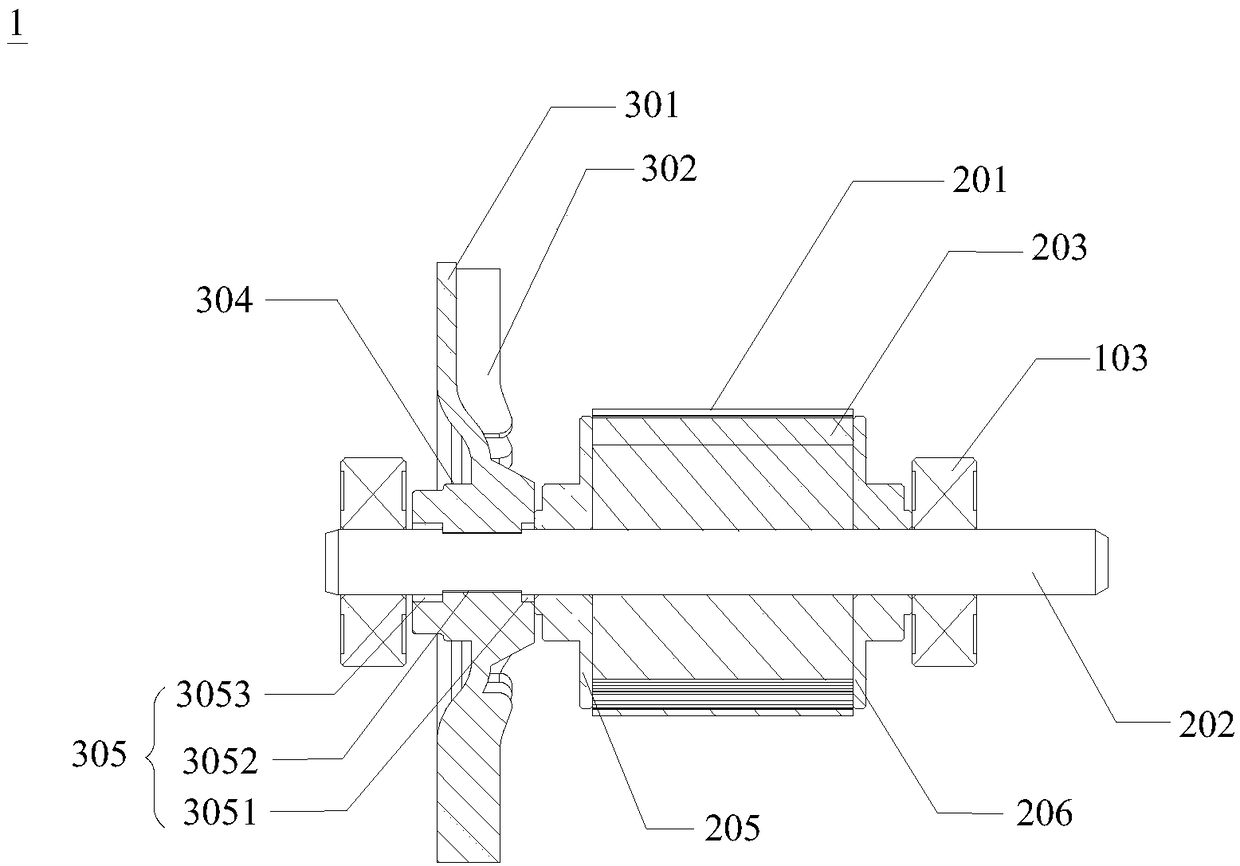

Bearing fixing structure

ActiveCN104033493APrevent radial rotationGuaranteed normal operationPump componentsPumpsEngineeringMechanical engineering

A bearing fixing structure comprises a bearing arranged in a shaft tube of a pedestal. The bearing has a close fit plug connection with a shaft center. A bearing fixing shell for accommodating the bearing is arranged between the bearing and the shaft tube. The bearing closely cooperates with the bearing fixing shell. The bearing fixing shell loosely cooperates with the shaft tube. The shaft tube has a at least one radial spacing portion, and the radial spacing portion abuts the at least one lug of the bearing fixing shell to restrict the radial rotation of the bearing fixing shell. An elastic element is arranged in the shaft tube, and is positioned below the bearing fixing shell in order to provide a preload pressure for the bearing fixing shell.

Owner:ASIA VITAL COMPONENTS (CHINA) CO LTD

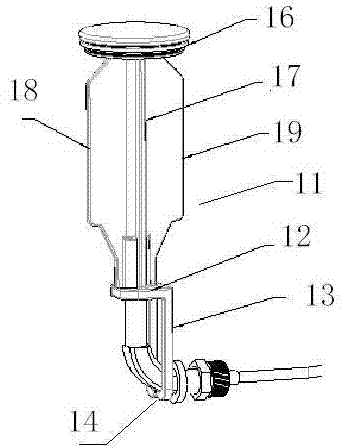

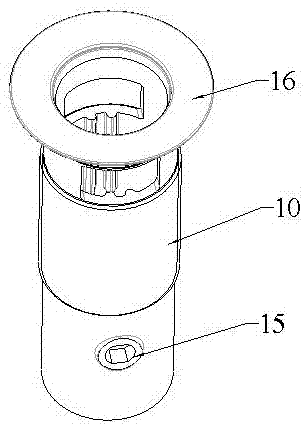

A pull-type drainage control device

The invention relates to a drainer, in particular to a lift-draw type drainage control device for kitchen and bathroom. The lift-draw type drainage control device comprises: a housing that is suitable for the installation in the drainhole of a pool; a piston slidingly matched with the housing; and a steel wire actuating device which is provided with a steel wire and a sleeving having a flexible sleeve and limited axial compression; the actuating end of the steel wire stretches into the housing and is combined with the lower part of the piston, and the controller of the steel wire actuating device is arranged outside the housing. The drainage control device is convenient for installation, and prevents blockage.

Owner:贝朗(中国)卫浴有限公司

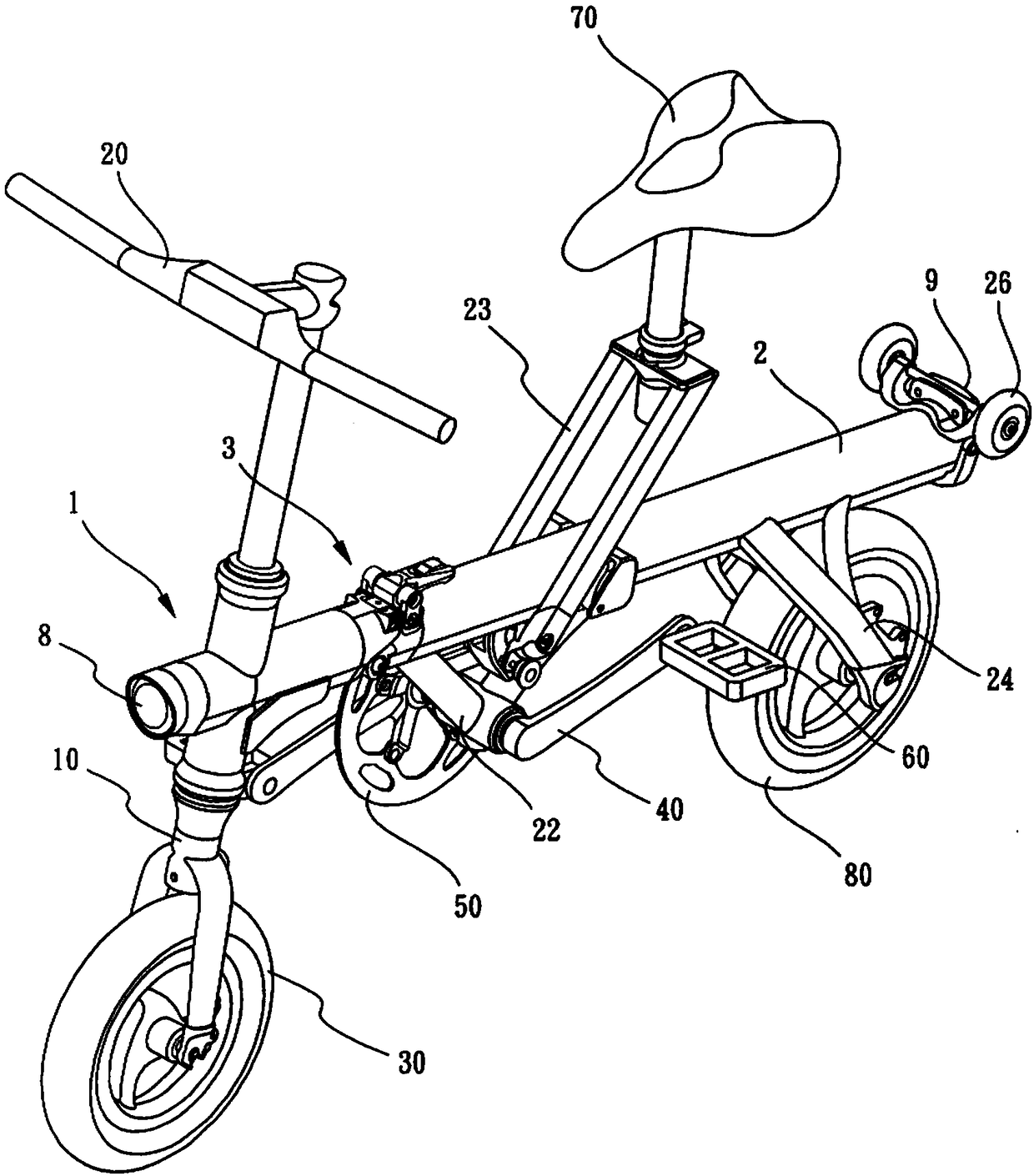

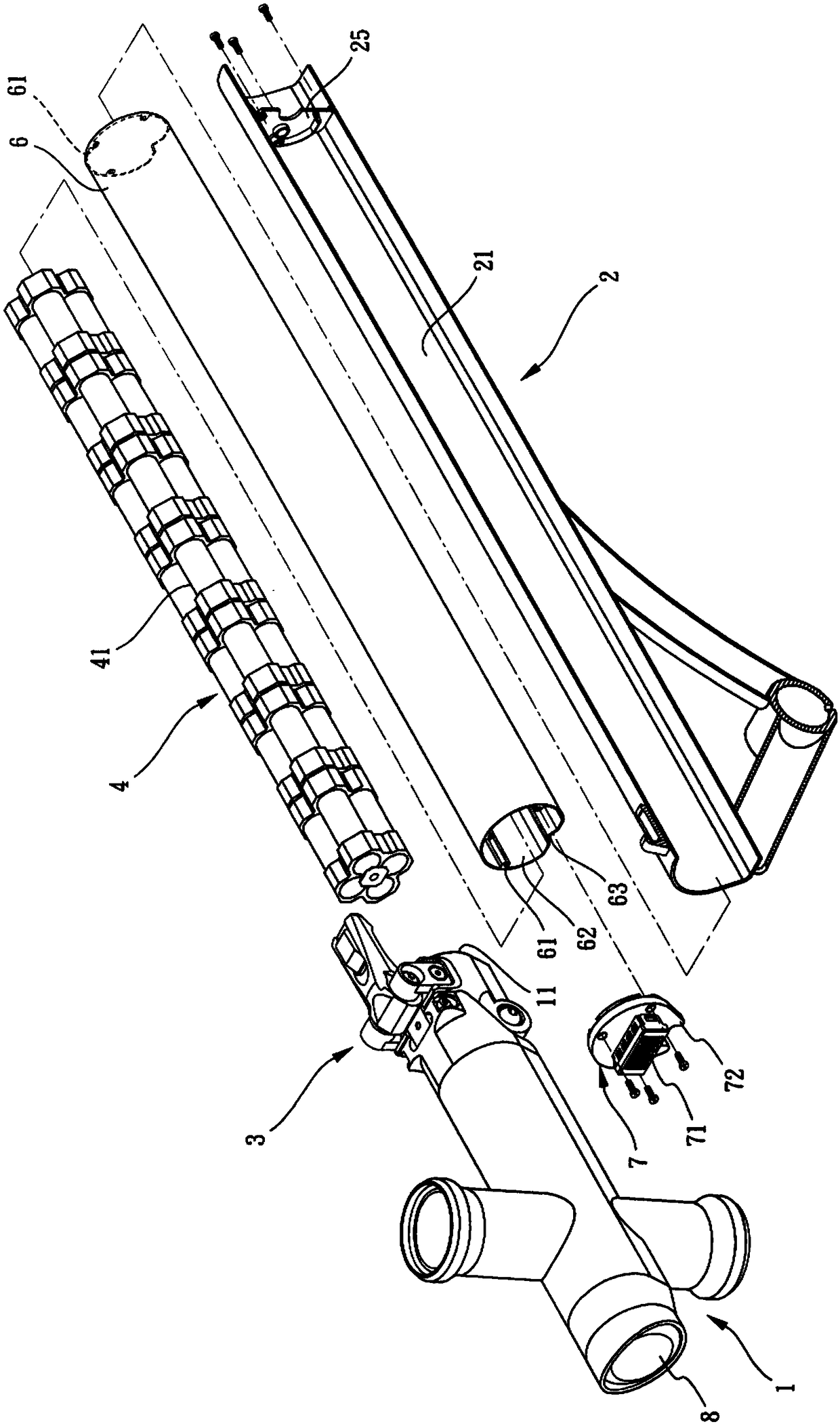

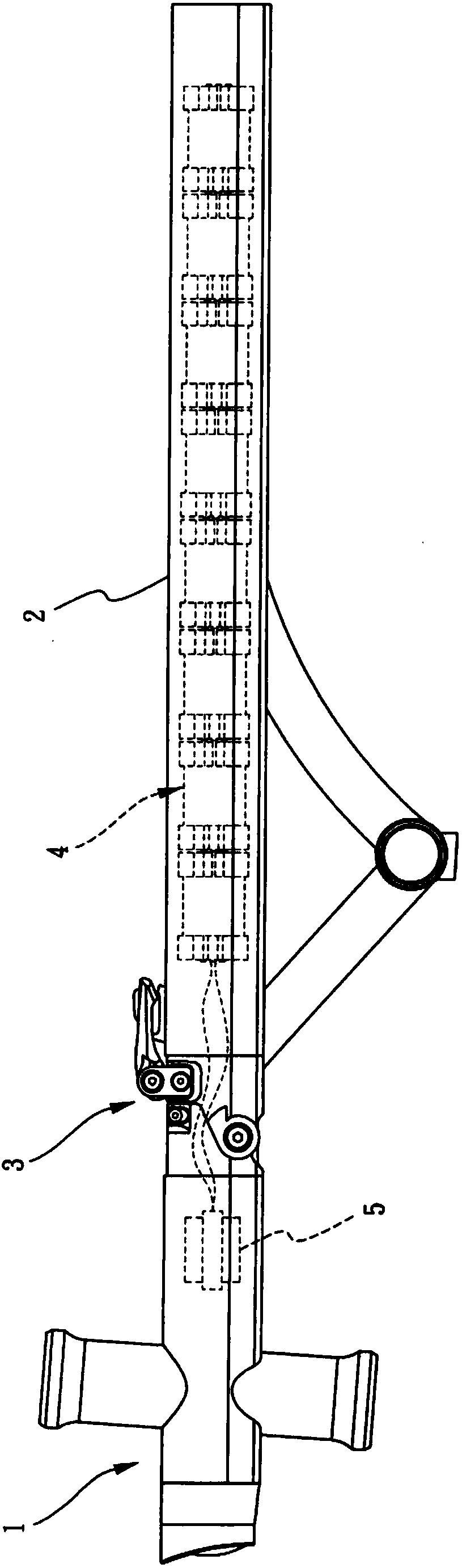

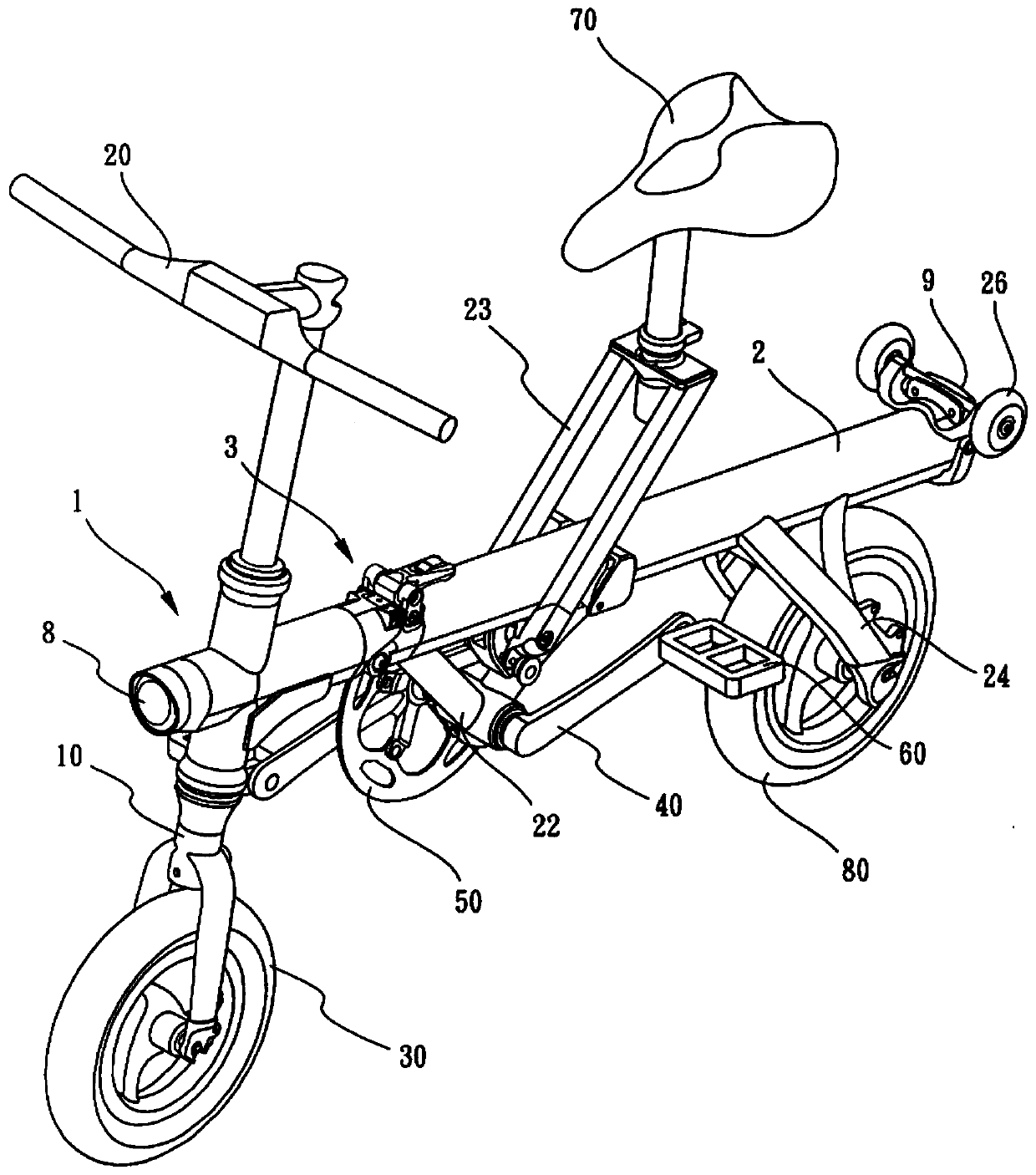

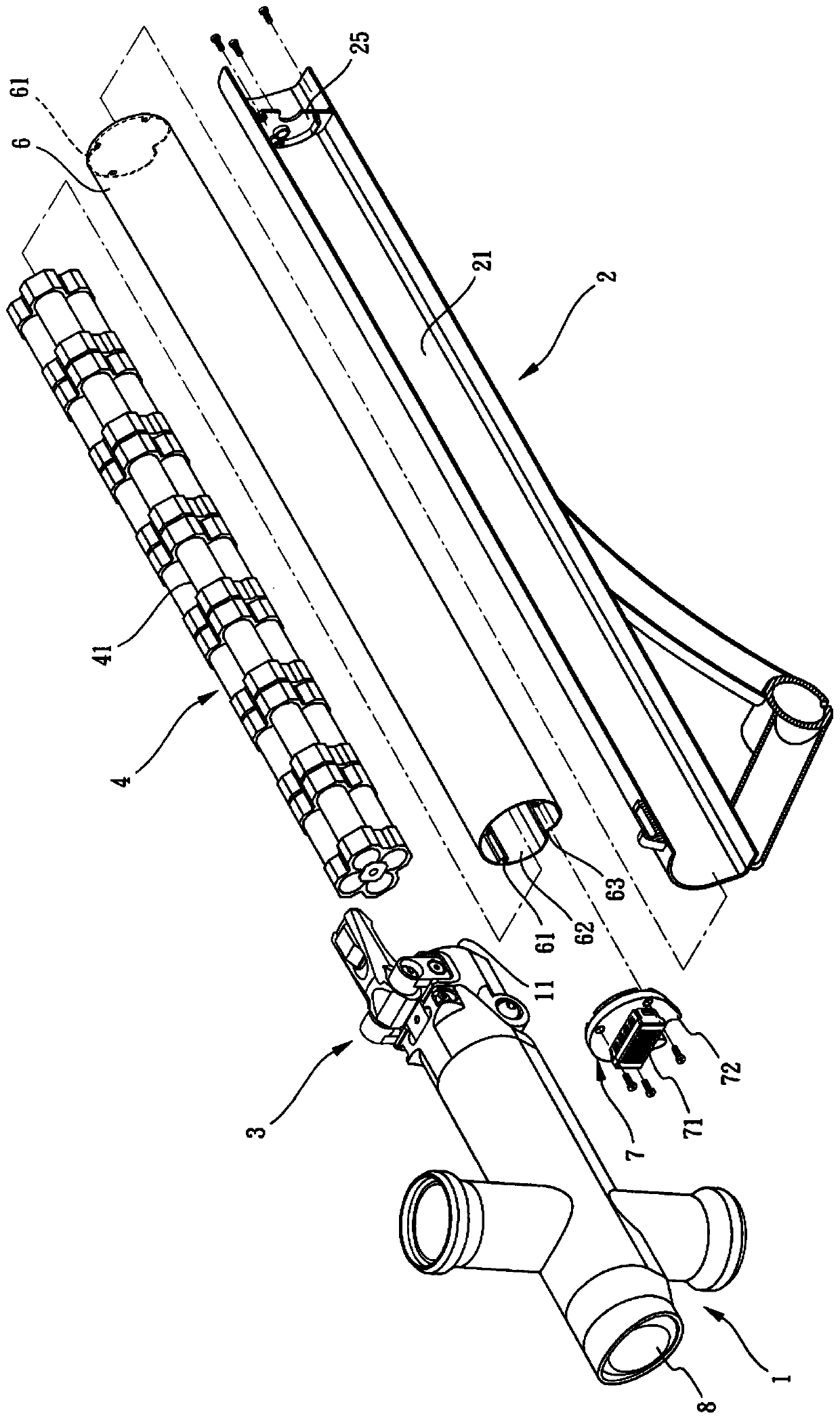

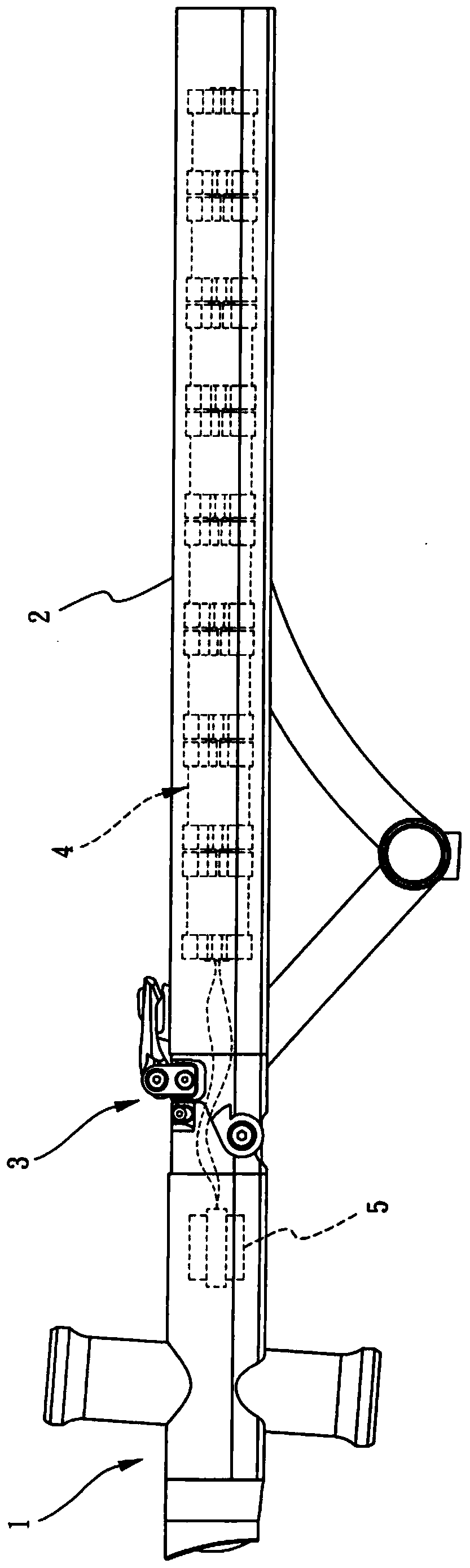

Bicycle pipe support capable of accommodating battery and being bent

ActiveCN108068964APrevent radial rotationEasy to installOptical signalCycle framesEngineeringPipe support

The invention provides a bicycle pipe support capable of accommodating a battery and being bent. The bicycle pipe support capable of accommodating the battery and being bent comprises a front pipe support, a rear pipe support, a bending assembly and a battery, wherein the bending assembly is used for pivoting the front pipe support and the rear pipe support; a front accommodating groove is arranged to extend inwards in the axial direction of the front pipe support; the front accommodating groove is used for accommodating a controller; a rear accommodating groove is arranged to extend inwards in the axial direction of the rear pipe support; the axial length of the front pipe support is 1 / 6-1 / 3 of the length of the rear pipe support; and the battery is accommodated within the rear accommodating groove of the rear pipe support and is electrically connected with the controller.

Owner:LEKUMA ENERGY TECH INC

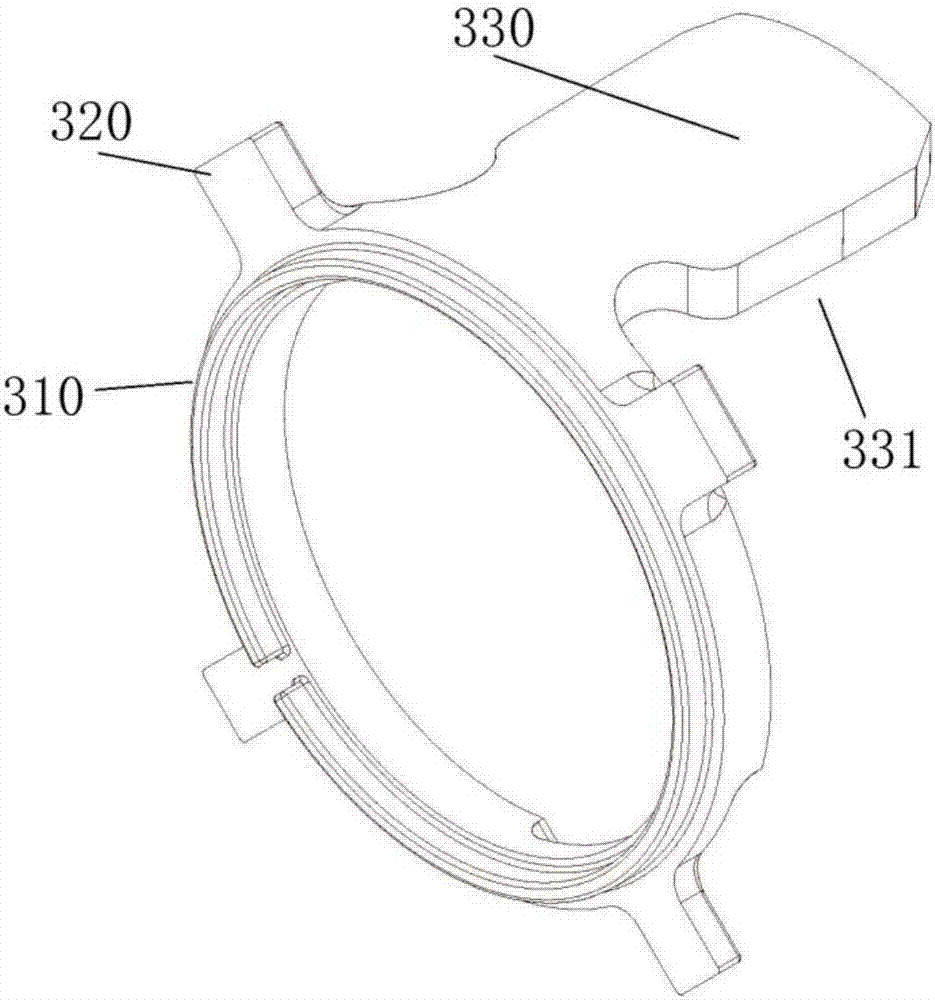

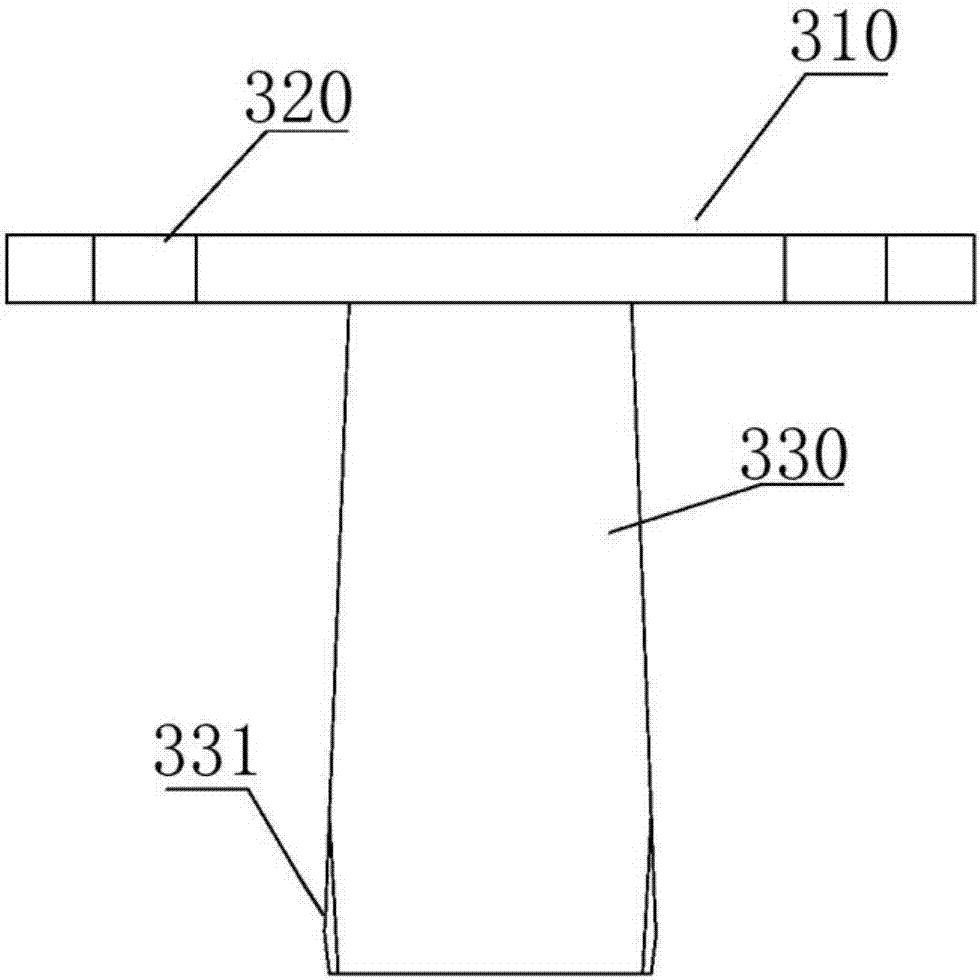

Locking ring for release bearing

PendingCN107013602AExtended service lifeNo costMechanical actuated clutchesBearing componentsFriction reductionMechanical engineering

The invention provides a locking ring for a release bearing. The locking ring comprises a ring-shaped connecting ring, a clamping lug and a lock tongue, wherein the clamping lug extends outwards along the radial direction of the outer edge of the connecting ring, and the lock tongue is vertical to the plane with the connecting ring and axially extends; the clamping lug is clamped into a corresponding clamping groove of a sliding sleeve of the release bearing, and the lock tongue is inserted into a corresponding lock groove in a shell of the release bearing. The locking ring has the advantages of simple structure and convenient processing and can further increase the lubrication level and reduce frictional loss on the basis of effectively avoiding radially rotating among the parts of the release bearing, and thus the service life of the release bearing is prolonged.

Owner:福缔汽车(太仓)有限公司

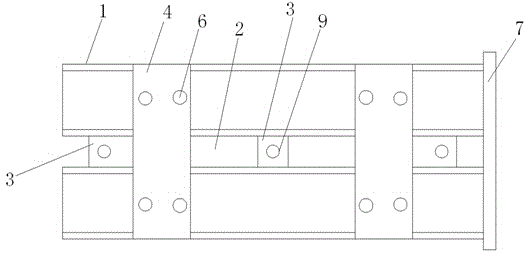

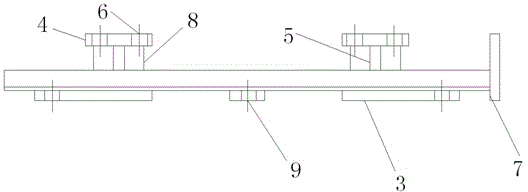

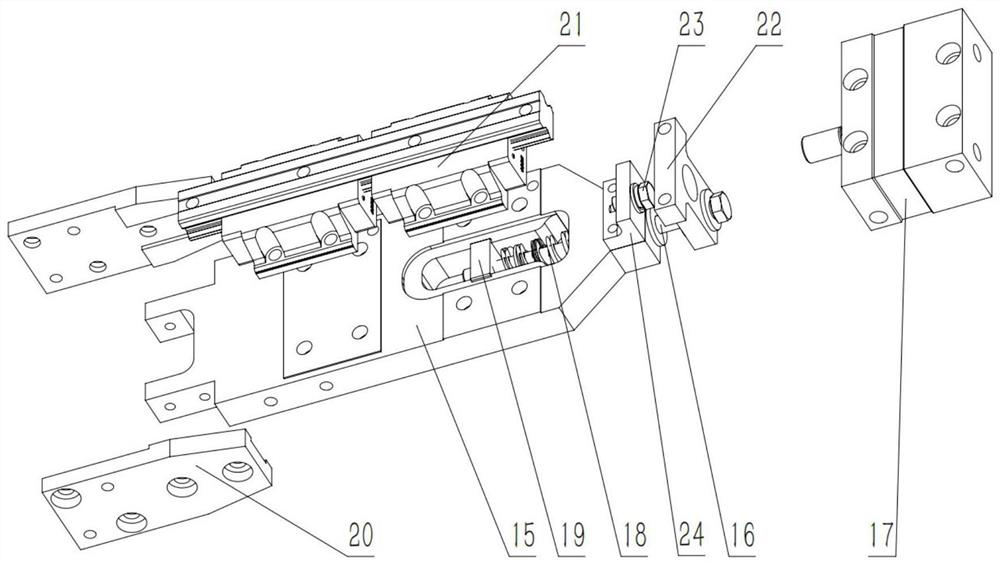

Hole drilling positioning die of top beam spring sleeve

The invention discloses a hole drilling positioning die of a top beam spring sleeve. The hole drilling positioning die comprises at least two sectional materials with U-shaped cross sections, the U-shaped sectional materials are laid in parallel and form a gap, a connecting plate is placed at the bottom of each U-shaped sectional material so that the U-shaped sectional materials can be connected together, a positioning plate is placed over each U-shaped sectional material, a supporting plate is arranged between each positioning plate and the position, at the gap, of the corresponding connecting plate to fix the positioning plate, a hole drilling positioning hole is formed in each positioning plate and is located over a center line of one single U-shaped sectional material, and U-shaped sectional material axial limiting is achieved on one sides of the U-shaped sectional materials by arranging baffles. By means of the hole drilling positioning die, the U-shaped sectional materials are arranged, so that radial rotation of the spring sleeve is prevented; the baffles are arranged for preventing axial movement of the spring sleeve, and the position of a machining hole in the spring sleeve can be effectively determined through the positioning plates above the baffles and the hole drilling positioning holes.

Owner:六盘水宏山托辊制造有限公司

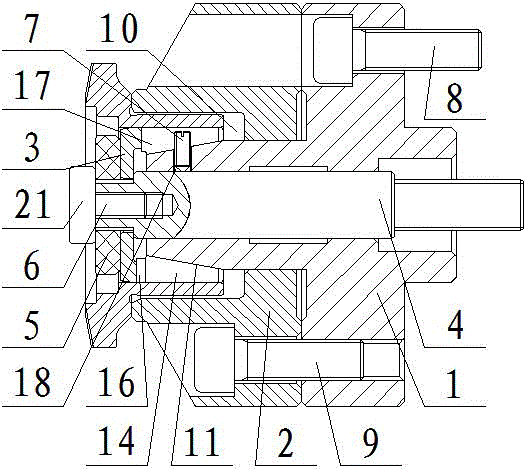

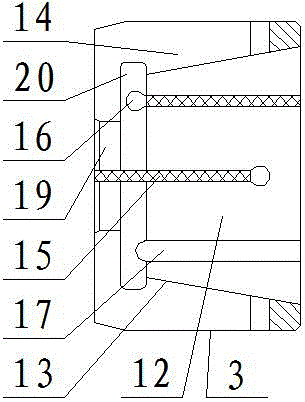

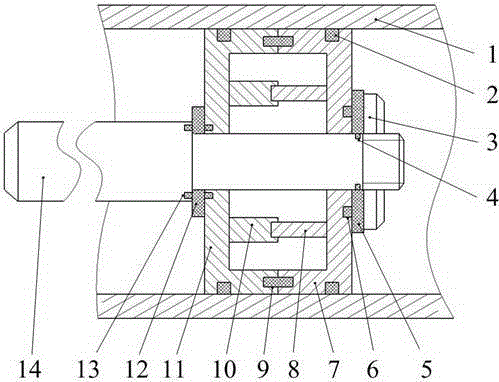

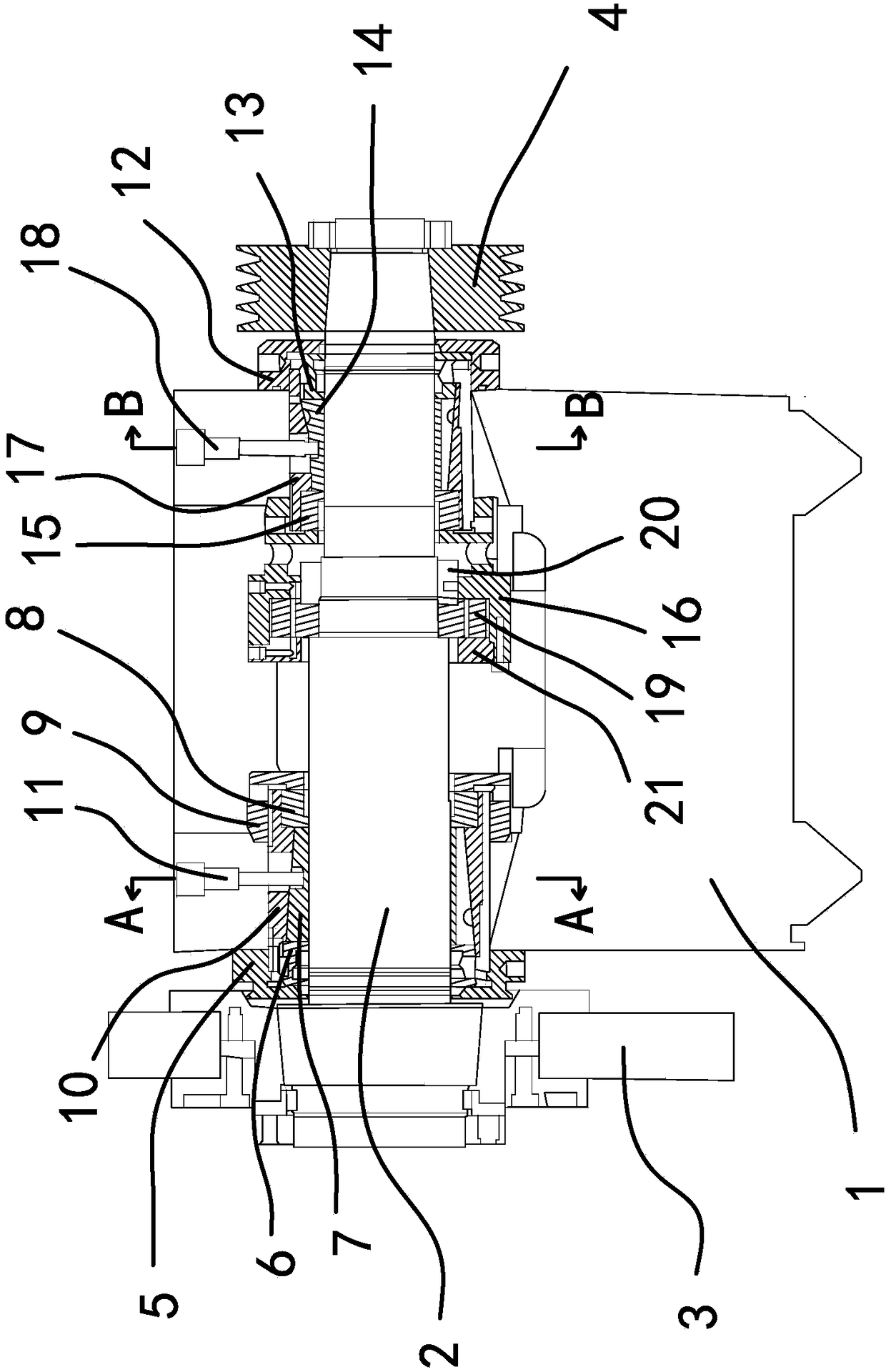

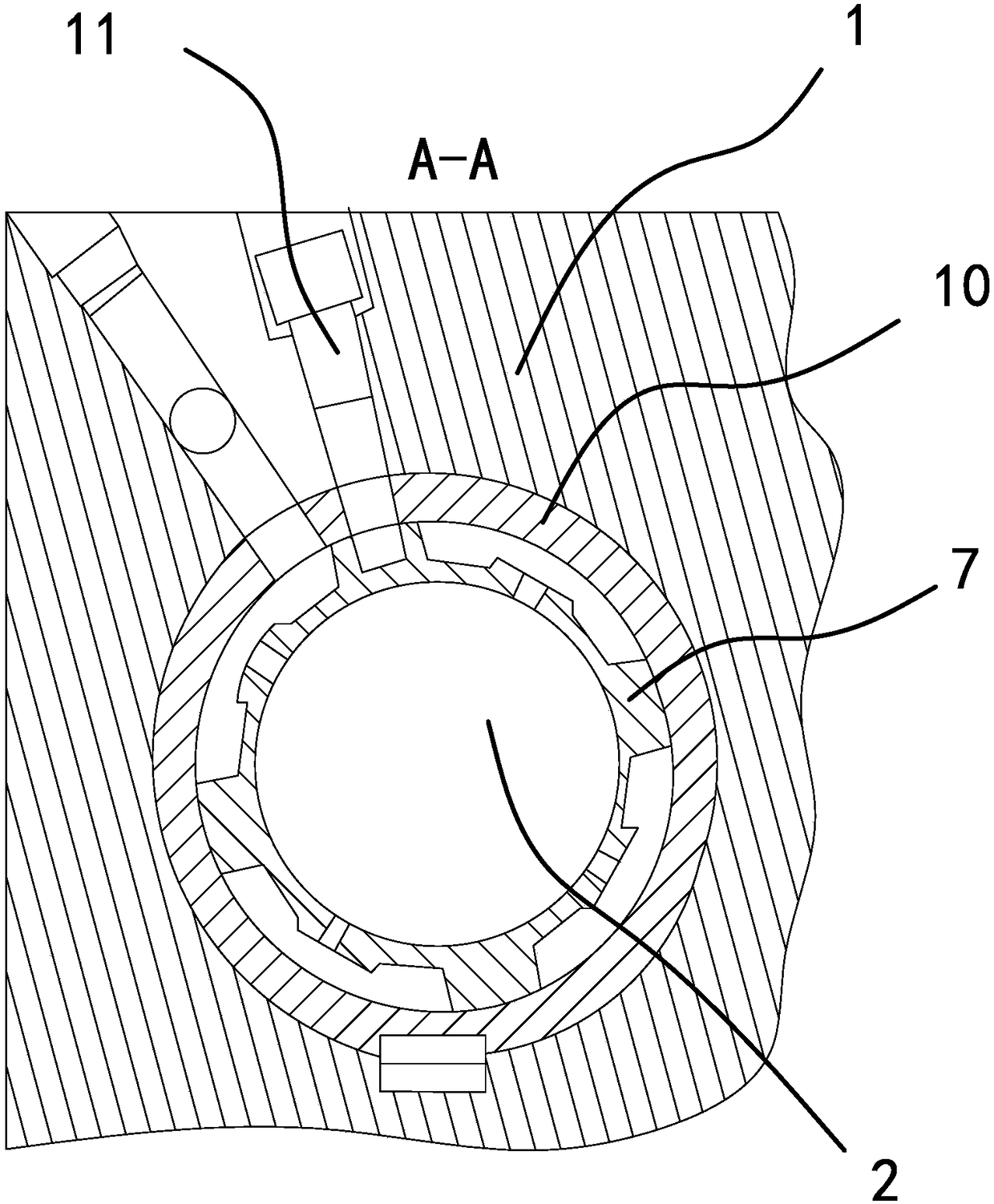

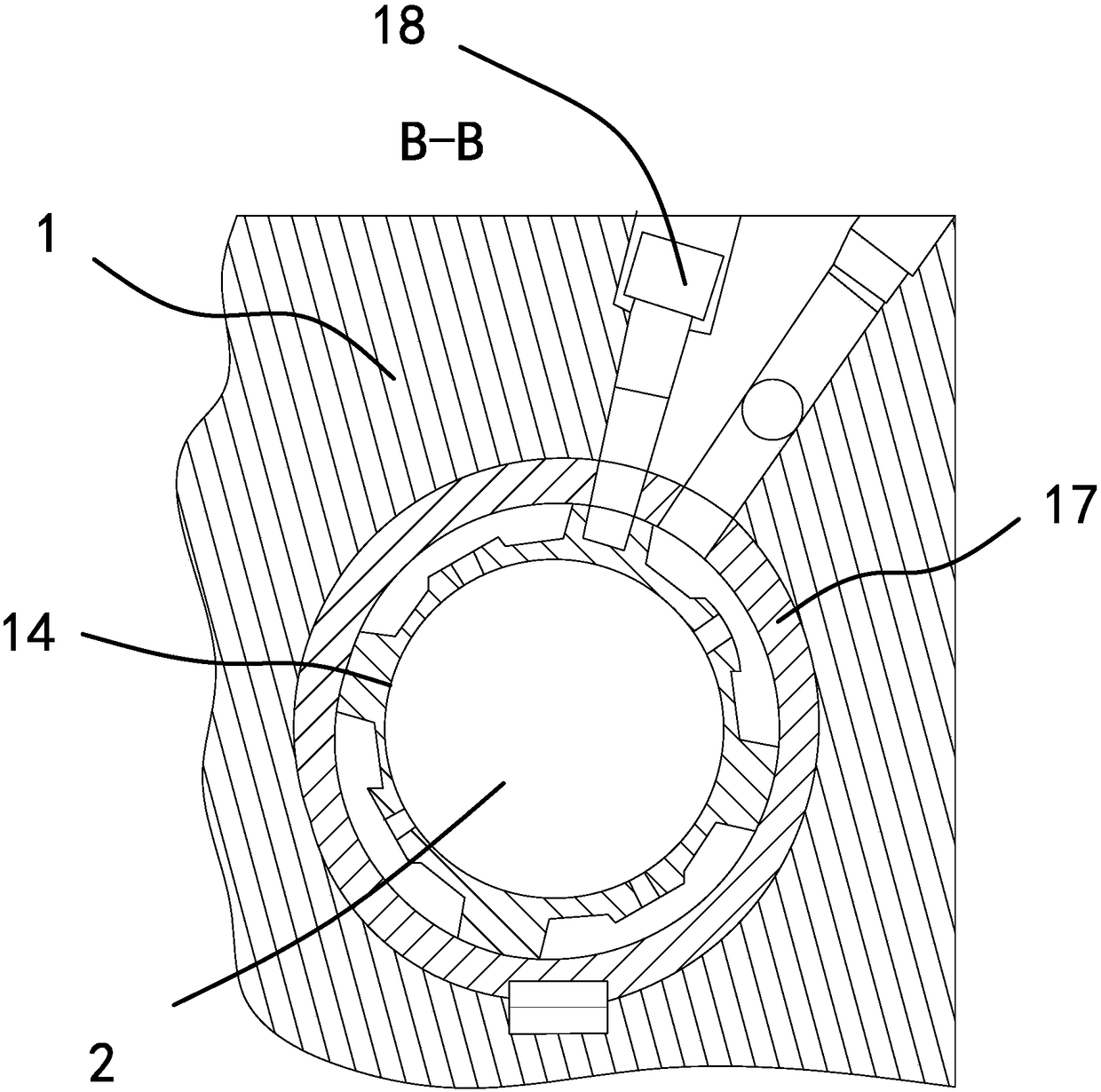

Combined connection device for preventing piston from rotating in radial direction and moving in axial direction

InactiveCN105179364AReduce weightEnhance oil pressure bearing capacityFluid-pressure actuatorsTorsional deformationEngineering

The invention provides a combined connection device for preventing a piston from rotating in the radial direction and moving in the axial direction. The combined connection device mainly comprises a cylinder barrel, a piston rod, a locking nut, an elastic gasket, an elastic check ring, a sealing ring, a buffer sleeve and the piston. The piston is formed by combining a piston disc A and a piston disc B. The combined connection device is characterized in that the piston is prevented from rotating in the radial direction and moving in the axial direction by means of a shaft shoulder of the piston rod, the locking nut, the elastic gasket with a protrusion, and torsional deformation of the elastic gasket. The weight of the piston is reduced without loss of strength through the hollow cylindrical piston discs provided with supporting columns; the elastic gasket, the protrusion on the elastic gasket, the shaft shoulder of the piston rod and the locking nut prevent the piston from rotating in the radial direction and moving in the axial direction; and the piston discs are prevented from impacting and colliding with each other through the buffer sleeve between the piston discs.

Owner:UNIV OF JINAN

Trailer

InactiveCN100448734CFirmly connectedPrevent axial movementOptical signallingDrum brakesEngineeringBrake shoe

The trailer includes mainly one hauling machine, one auxiliary frame, one suspension device, one braking device and one tail lamp system. It features the suspension device with one nearly square torsion piece combination comprising elastic steel pieces; the braking device with one braking shoe assembly comprising one double layered rocker, two locating pins, one braking shoe plate and one braking friction sheet; the tail lamp system with at least one transition connector connected between one plug and one socket. The trailer has the advantages of capacity of being connected with different kinds of tractor, smooth running, etc.

Owner:北京军适机械有限公司

Conical roller

PendingCN111470284AMeet different size requirementsSolve the real problemRollersLogistics managementStructural engineering

Owner:ZHEJIANG DAMON IND EQUIP CO LTD

A copper-plastic composite pipe

The invention relates to a pipeline part, and in particular relates to a copper plastic compound pipe. The invention provides a copper plastic compound pipe which is provided with a first open end and a second open end. The copper plastic compound pipe comprises a copper pipe layer and a plastic pipe layer positioned at the interior of the copper pipe layer, and the part, positioned at the first open end, of the plastic pipe layer radially packages the end of the copper pipe layer so as to form a package part; the radial edge of the package part forms a reentry which extends toward the second open end, and the inner wall of the reentry is fitly fixed on the outer wall of the copper pipe layer; and the inner wall of the reentry is fitly fixed on the outer wall of the copper pipe layer so as to prevent the copper pipe layer of the molded copper plastic compound pipe from shifting axially, so that the fixed effect is good, thereby preventing the leakage caused by the looseness of the copper pipe layer and the plastic pipe layer.

Owner:GUANGZHOU SEAGULL KITCHEN & BATH PROD

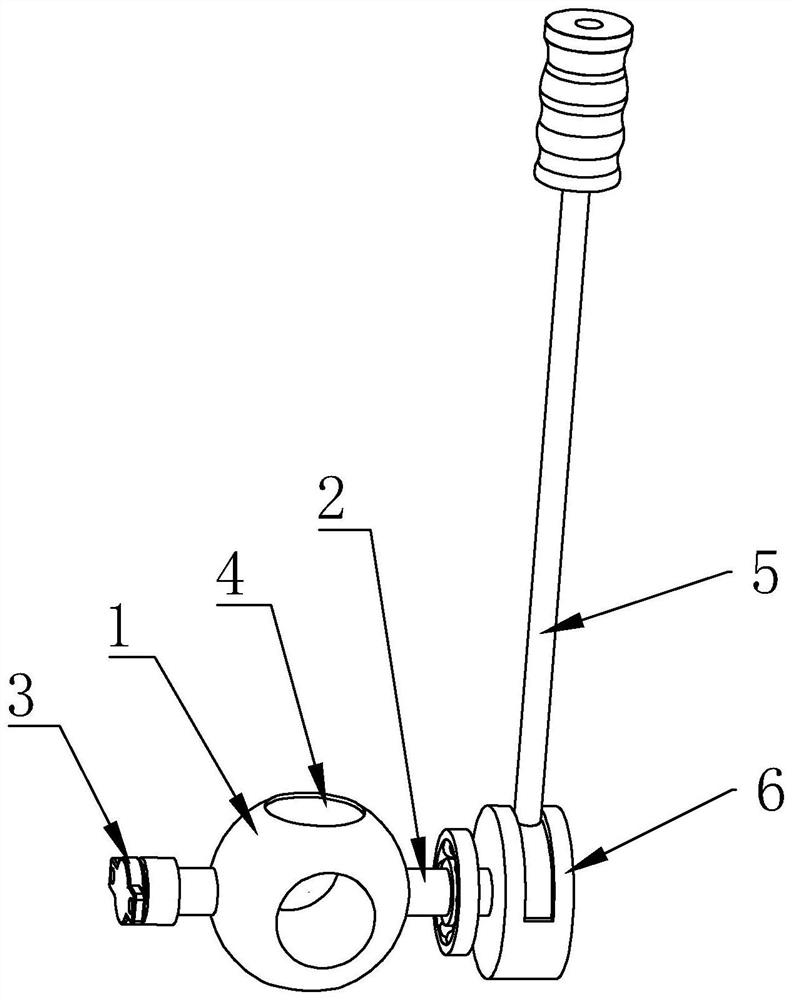

Pedal of motorcycle

Owner:万李

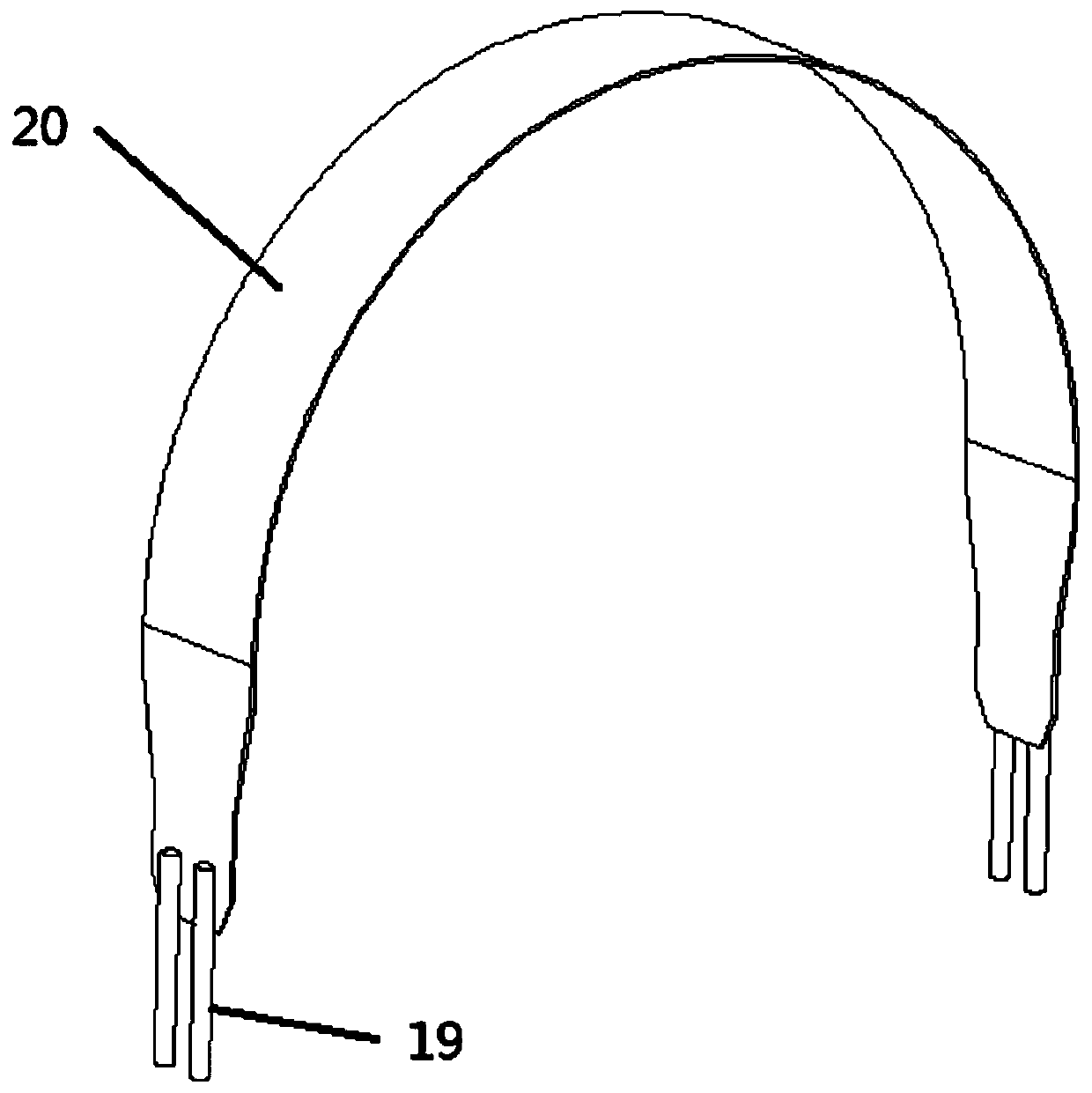

Simple orthodontic indirect bonding bracket transfer device in clinical diagnosis room

InactiveCN111419441ANot easy to remove and change proofreadingRealize connection installationBracketsOral problemsDental cast

The invention discloses a simple orthodontic indirect bonding bracket transfer device in a clinical diagnosis room, and relates to the technical field of orthodontic correction. Aiming at the problemsthat: according to traditional orthodontic indirect bonding bracket transferring devices, when a bracket is transferred and connected to a dental cast, an upper die and a lower die easily act as a block and are not easy to disassemble, change and calibrate again, the upper die and the lower die need to be opened when the bracket on the inner side of the dental cast is inspected, and thus the bracket cannot be visually displayed, the invention provides the following scheme. The device comprises a first transfer dental cast, a second transfer dental cast and a cylinder bridge, and a cylindricalknob is rotatably connected to the inner middle of the cylinder bridge. According to the invention, through the design of the cylinder bridge and related structures in the cylinder bridge, the connecting installation and rapid disassembly between the first transfer dental cast and the second transfer dental cast are conveniently realized, the first transfer dental cast and the second transfer dental cast can be rotationally adjusted to be in an open state, the first transfer dental cast and the second transfer dental cast in the open state are fixed, and the bracket bonding effect can be conveniently and visually displayed.

Owner:马莉莉

Spindle structure on precision grinder

InactiveCN108527152APrevent radial rotationGrinding machine componentsGrinding wheelMechanical engineering

The invention provides a spindle structure on a precision grinder, and belongs to the technical field of machines. The problem that an existing dynamic and static pressure spindle is poor in grindingeffect is solved. The spindle structure on the precision grinder is arranged on a grinding wheel frame, a spindle is included, the left end of the spindle is connected with a grinding wheel, the rightend of the spindle is connected with a belt wheel, a left main locking nut, a left main check ring, a left bearing bush with an outer conical face, a left auxiliary check ring and a left auxiliary locking nut are arranged at the left end of the spindle, a left shaft sleeve with an inner conical face is in threaded connection between the left main locking nut and the left auxiliary locking nut, the left bearing bush is fixedly connected with the left shaft sleeve through a left positioning screw, a right locking nut, a right main check ring, a right bearing bush with an outer conical face, a right auxiliary check ring and a thrust locking nut are arranged at the right end of the spindle, a right shaft sleeve with an inner conical face is in threaded connection between the right locking nutand the thrust locking nut, and the right bearing bush and the right shaft sleeve are fixedly connected through a right positioning screw. The spindle structure has the beneficial effects of being high in rigidity, and small in offset during grinding of the spindle center.

Owner:宁波赫力奥斯机电设备有限公司

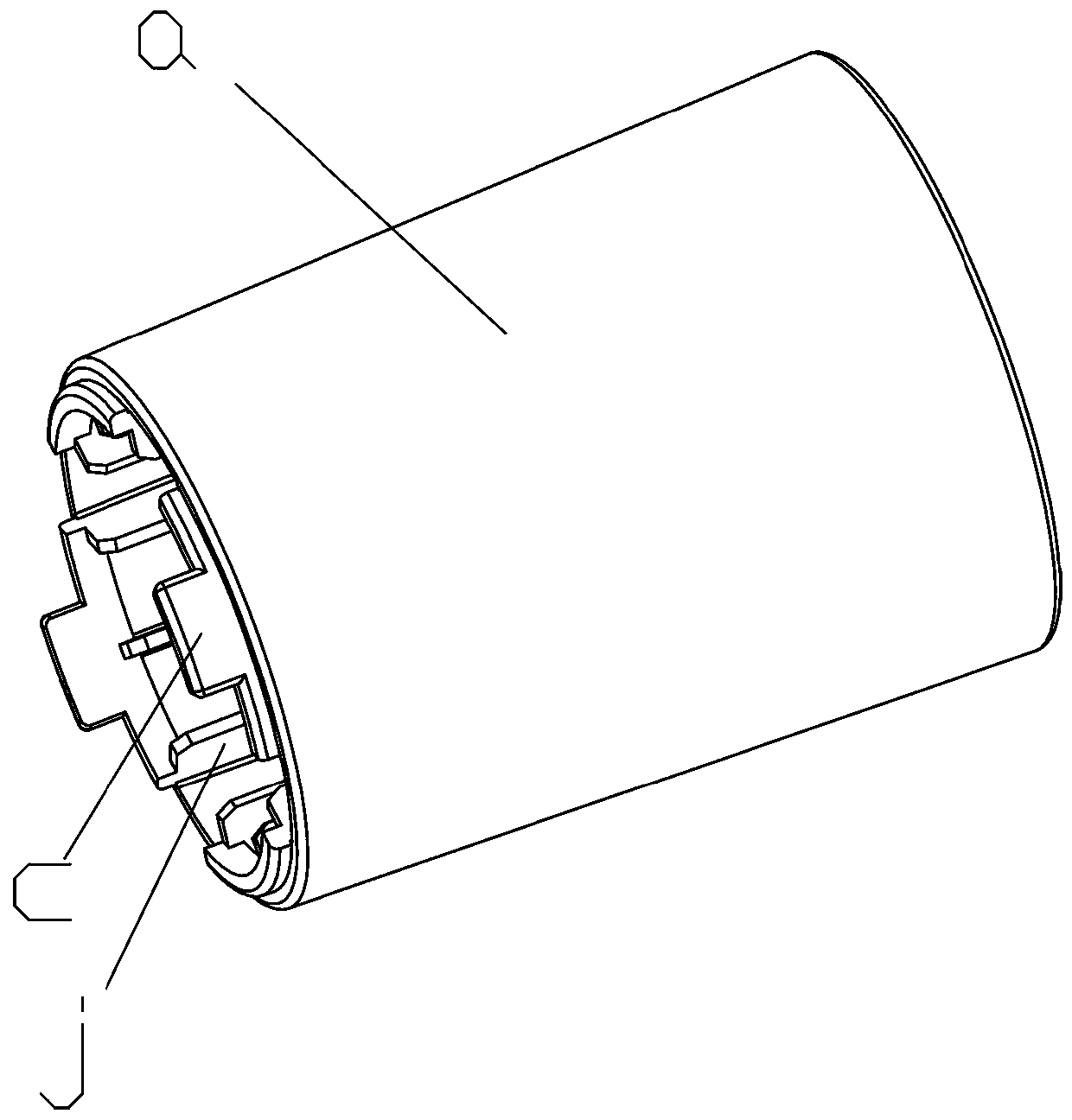

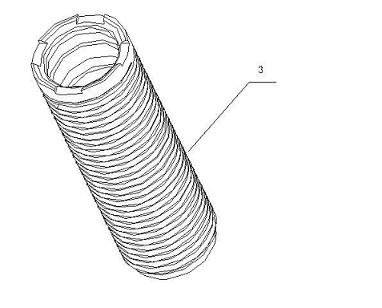

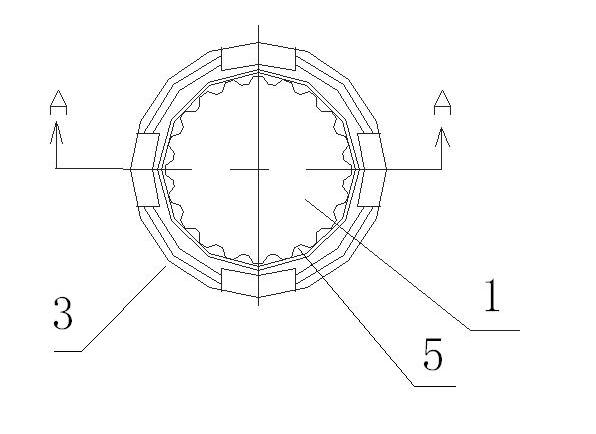

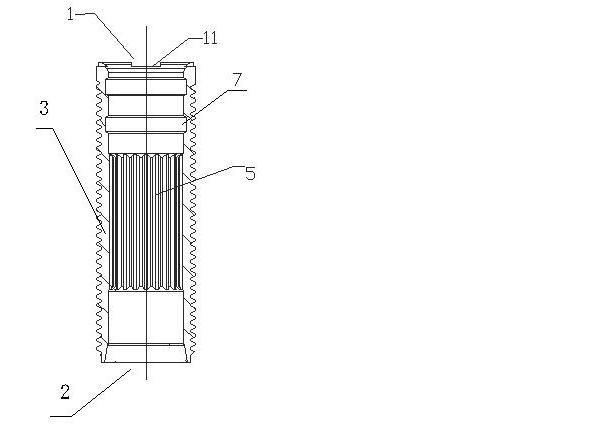

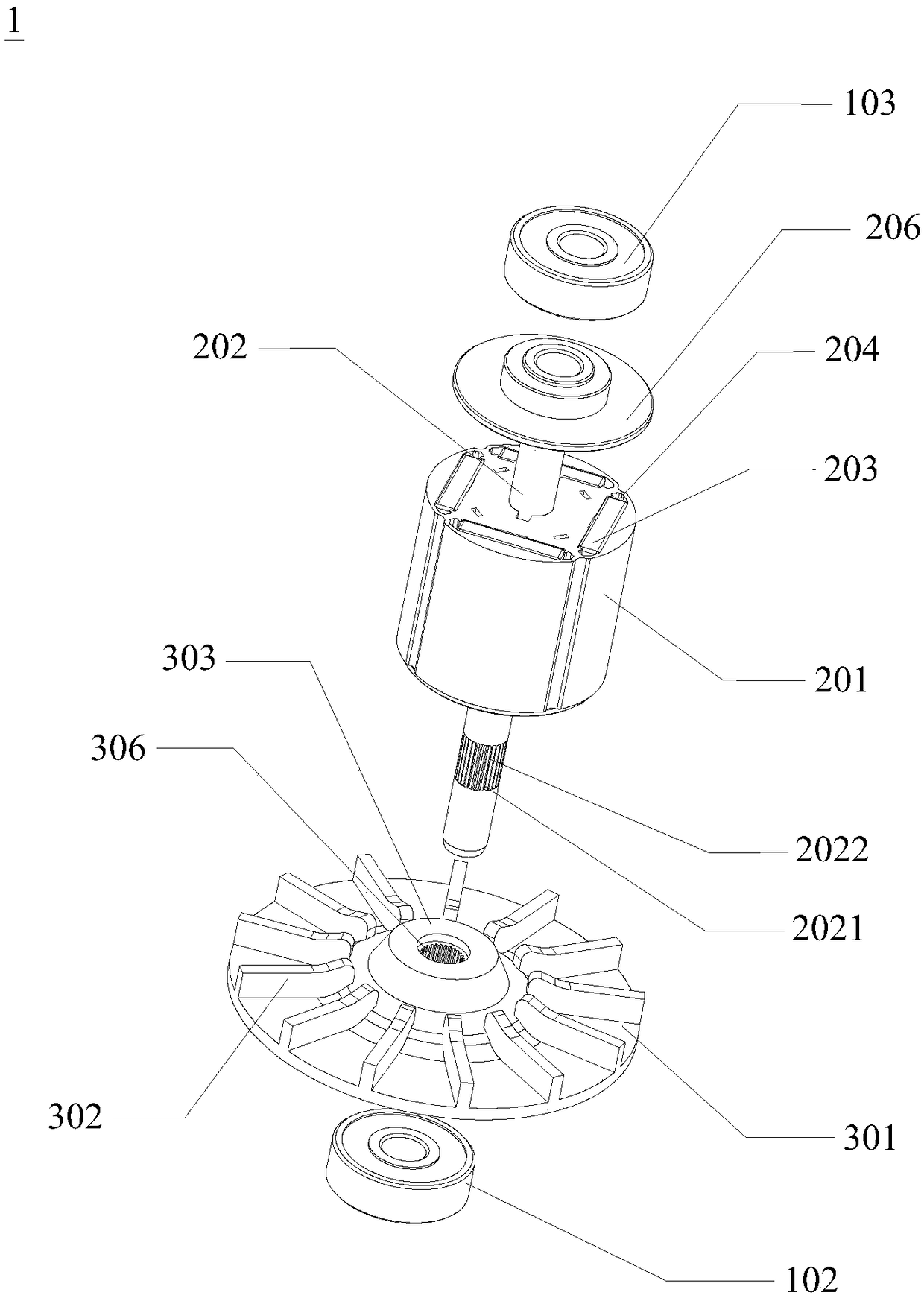

Brushless motor

PendingCN108923583AImprove job stabilityPrevent radial rotationMechanical energy handlingCooling/ventillation arrangementAxial displacementBrushless motors

The invention discloses a brushless motor. The brushless motor comprises a stator assembly, a rotor assembly and a fan blade, wherein the rotor assembly is arranged in the stator assembly, the fan blade is fixed on a shaft core of the rotor assembly, a straight-line knurling part is formed on the shaft core, and a through hole of the fan blade is in interference fit with the straight-line knurlingpart so that the fan blade is fixed on the shaft core. Compared with the prior art, the straight-line knurling part is formed on the shaft core of the brushless motor, and the through hole of the fanblade is in interference fit with the straight-line knurling part so that the fan blade is fixed on the shaft core; by interference fit of the fan blade and the straight-line knurling part, radial rotation of the fan blade can be prevented, axial displacement of the fan blade can be effectively prevented, so that the fan blade is prevented from falling off from the shaft core, and the working stability of the motor is improved.

Owner:东兴昌科技(深圳)有限公司

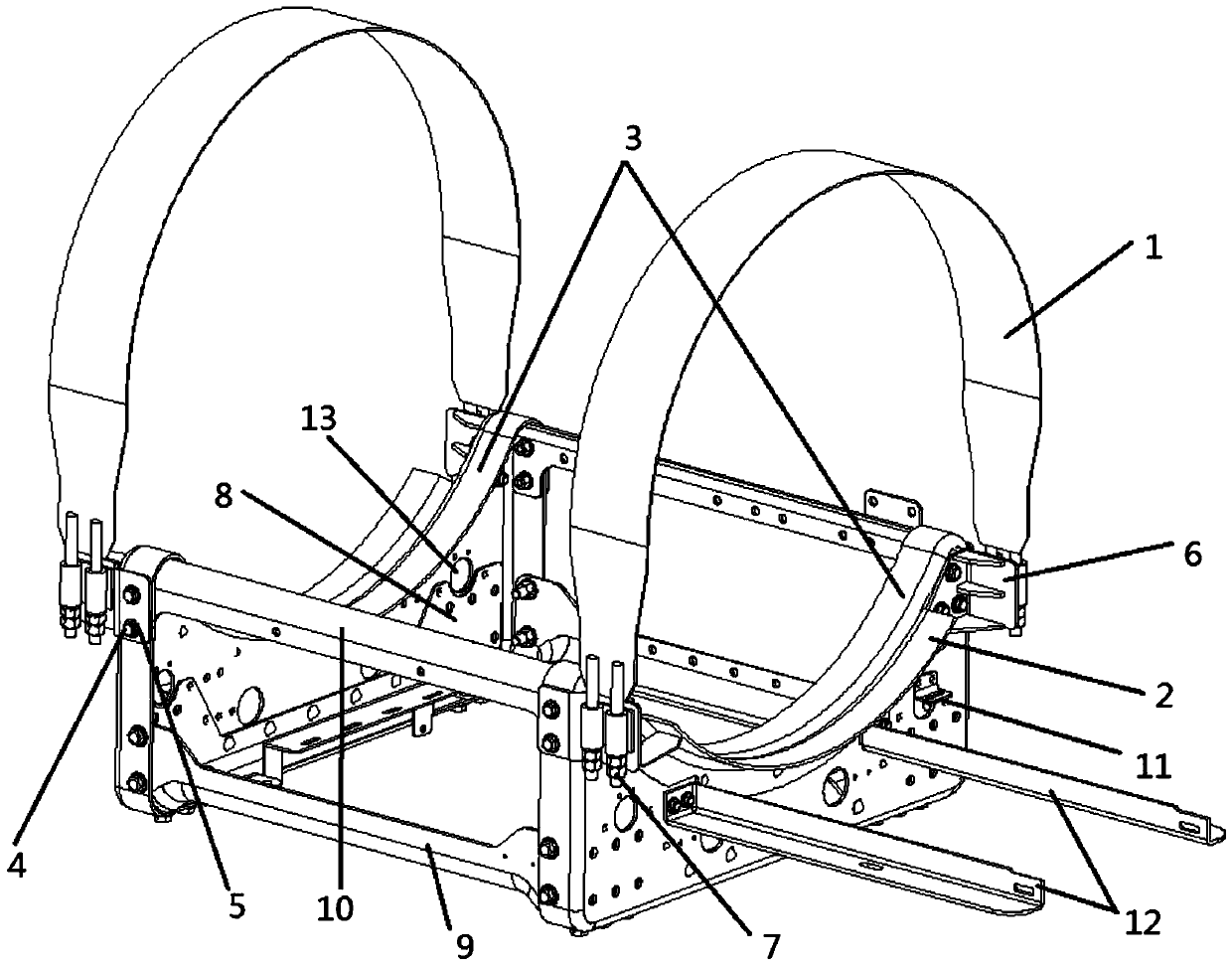

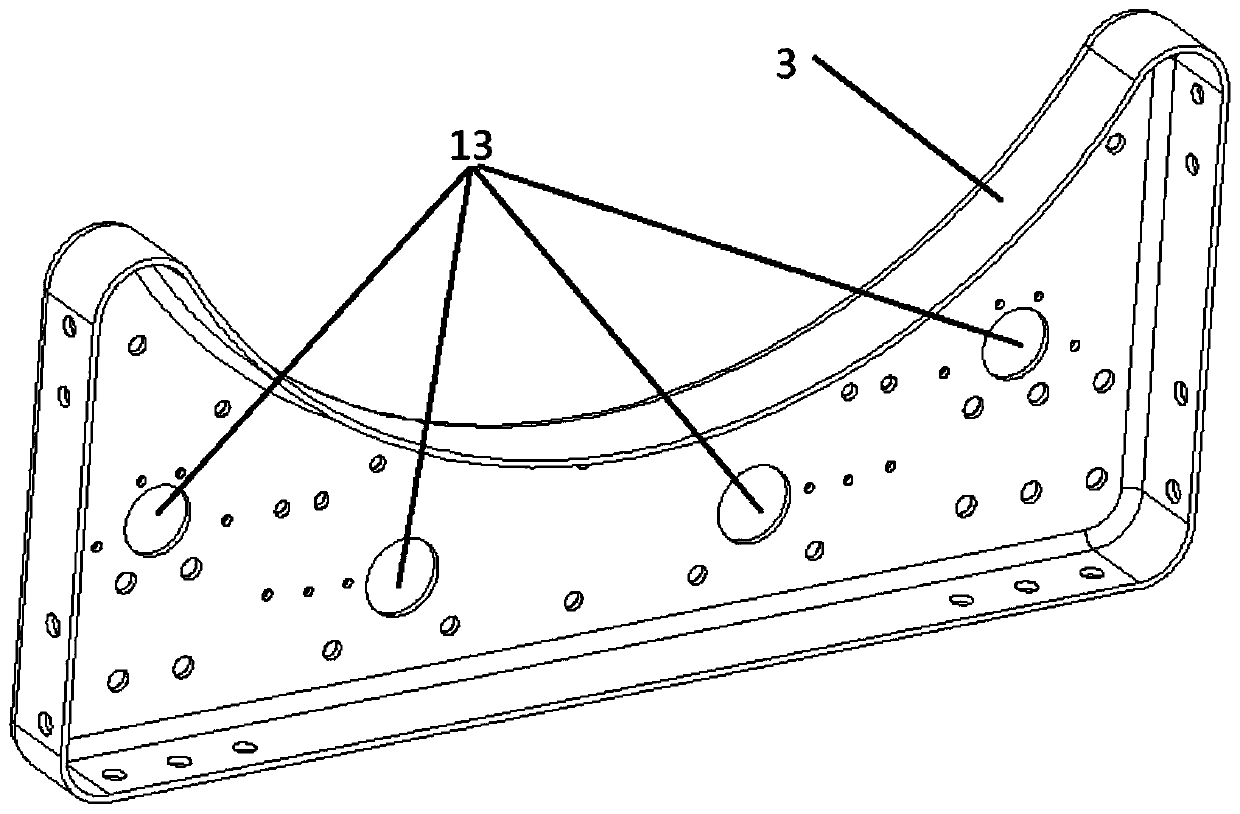

Non-bottom-beam frame for commercial vehicle liquefied gas bottles

PendingCN110001388AChange the welding structureAvoid welding deformationFuel supplyGas cylinderSelf locking

The invention discloses a non-bottom-beam frame for commercial vehicle liquefied gas bottles, and relates to the field of commercial vehicles. The non-bottom-beam frame for the commercial vehicle liquefied gas bottles comprises two saddles and pull belt assemblies correspondingly and detachably connected to the two saddles, wherein an upper cross beam and a lower cross beam which are parallel to each other are correspondingly connected between the two saddles through self-locking bolts and self-locking nuts, and detachable outer arc plates are correspondingly arranged on the outer side walls of the saddles; the shapes of the upper end faces of the saddles and the outer arc plates are matched with the external diameters of the liquefied gas bottles and are positioned on the same circular arc surface, and a symmetrical anti-rotation bracket is further arranged on the middle part of the outer side wall of one of the saddles; and ventral plates are correspondingly fixed to the inner side walls of the two saddles in a riveted mode. According to the non-bottom-beam frame for the commercial vehicle liquefied gas bottles, the problems of welding deformation of the frame, difficult disassembly and assembly and radial rotation and axial movement of the liquefied gas bottles occurring in the vehicle driving process are solved, the weight and production costs of products are further reduced by more than 30%, and the non-bottom-beam frame for the commercial vehicle liquefied gas bottles has great significance for popularization.

Owner:WUHU QINHUI TECH

Copper plastic compound pipe

The invention relates to a pipeline part, and in particular relates to a copper plastic compound pipe. The invention provides a copper plastic compound pipe which is provided with a first open end and a second open end. The copper plastic compound pipe comprises a copper pipe layer and a plastic pipe layer positioned at the interior of the copper pipe layer, and the part, positioned at the first open end, of the plastic pipe layer radially packages the end of the copper pipe layer so as to form a package part; the radial edge of the package part forms a reentry which extends toward the second open end, and the inner wall of the reentry is fitly fixed on the outer wall of the copper pipe layer; and the inner wall of the reentry is fitly fixed on the outer wall of the copper pipe layer so as to prevent the copper pipe layer of the molded copper plastic compound pipe from shifting axially, so that the fixed effect is good, thereby preventing the leakage caused by the looseness of the copper pipe layer and the plastic pipe layer.

Owner:GUANGZHOU SEAGULL KITCHEN & BATH PROD

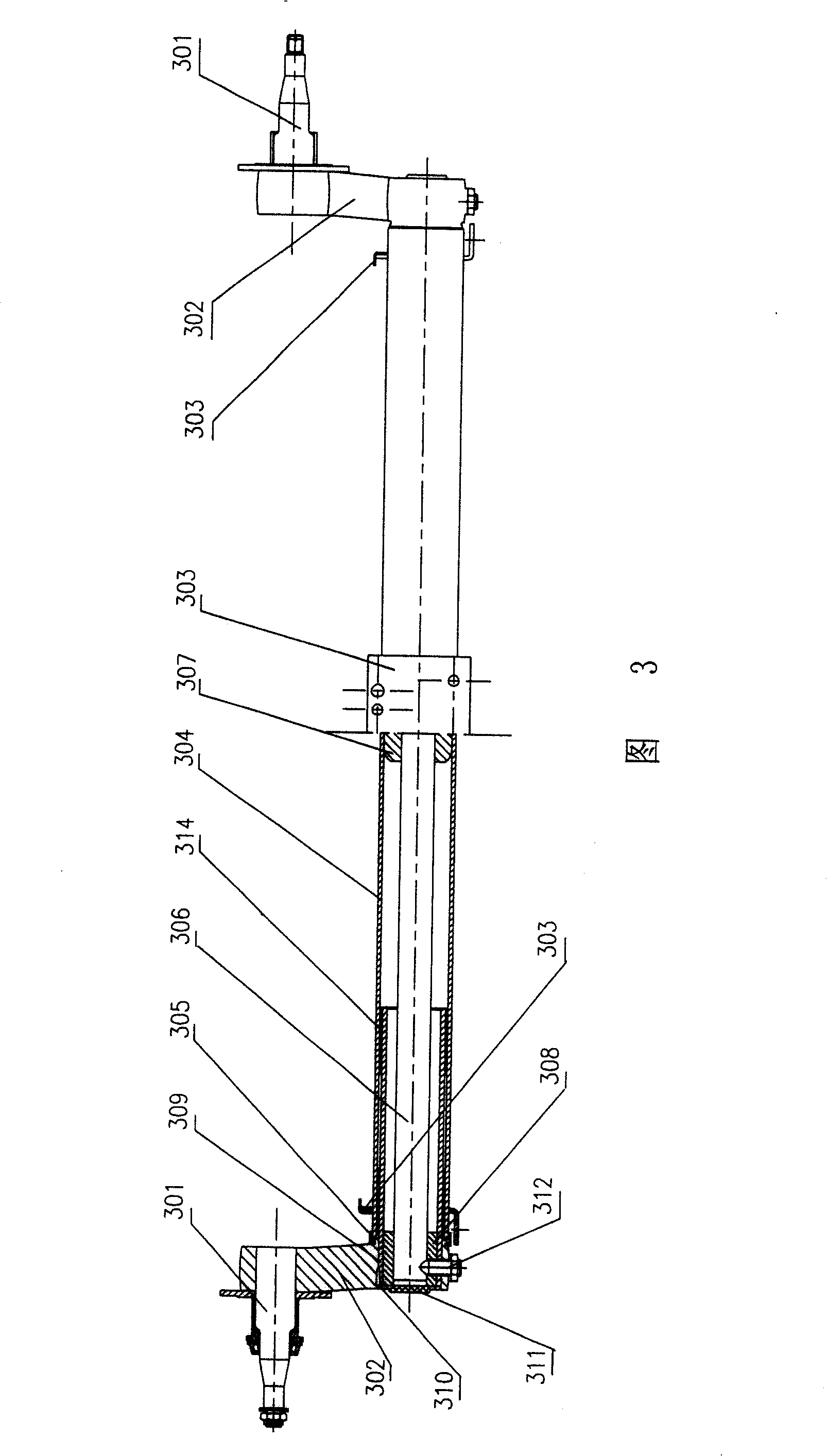

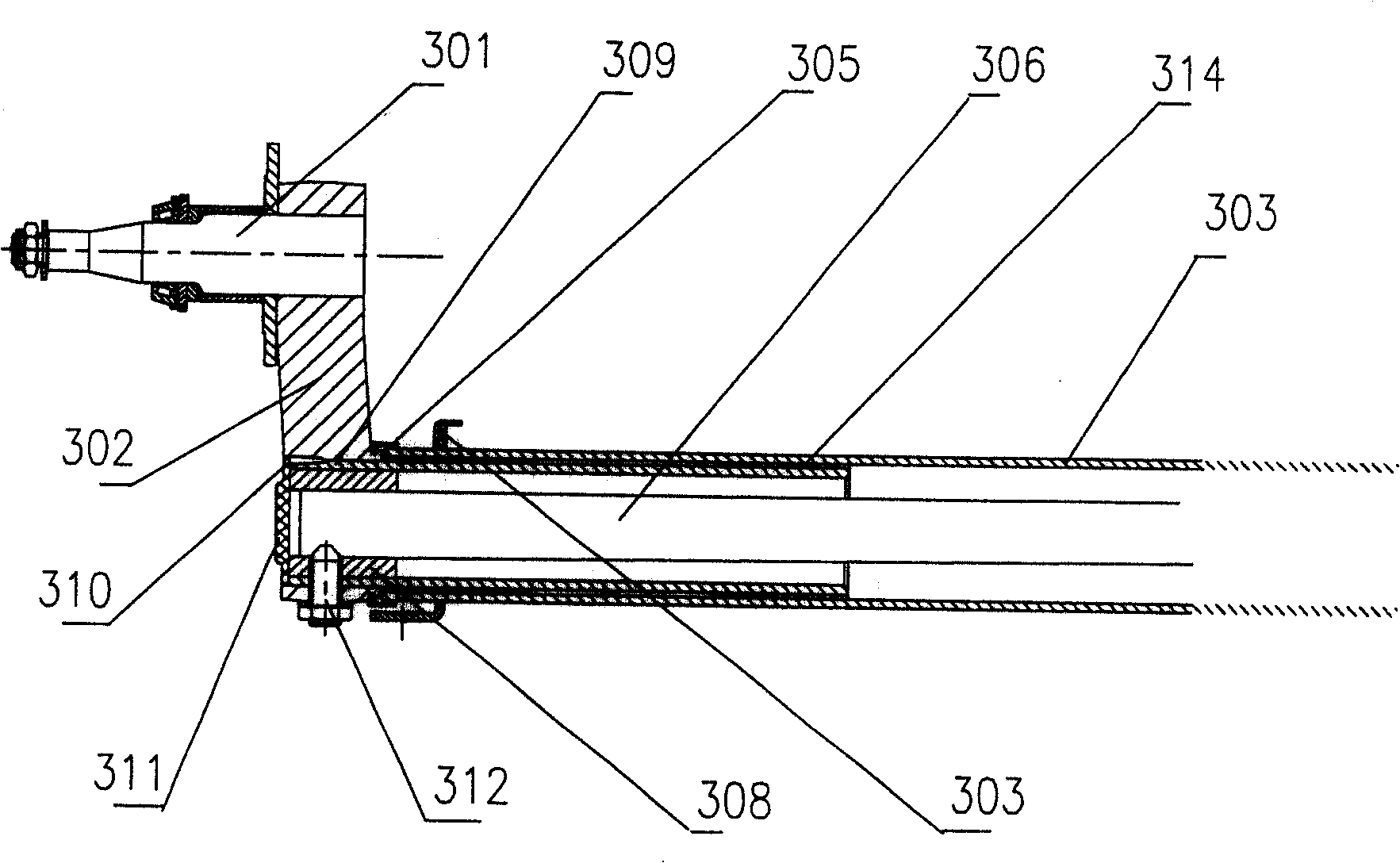

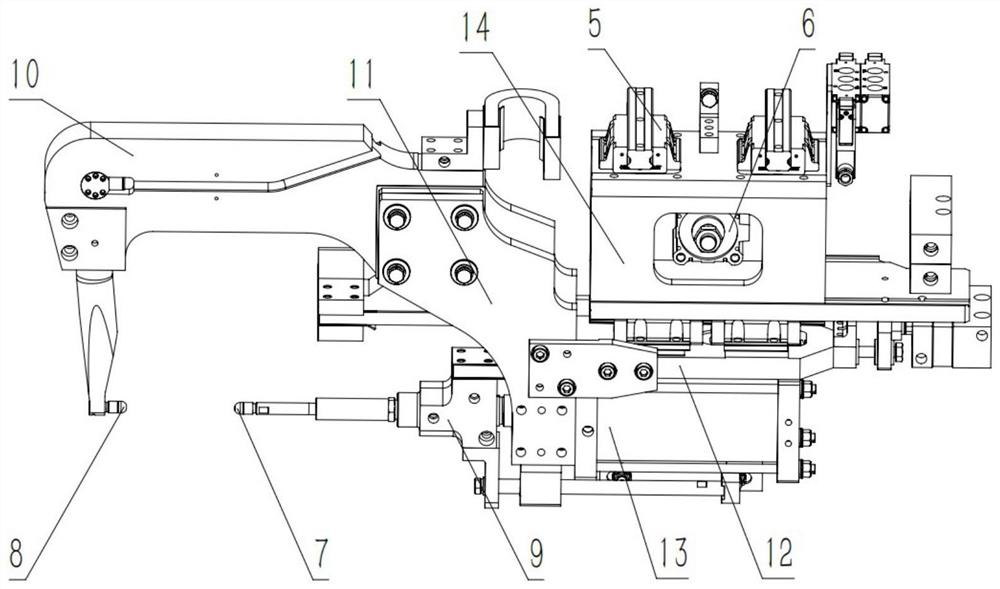

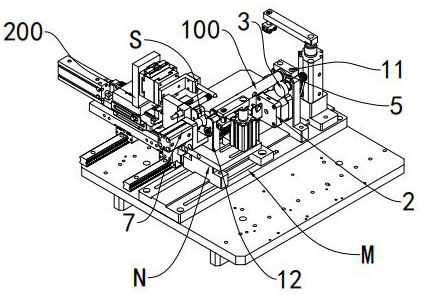

Double-spot double-face floating welding gun

InactiveCN113319492AImprove stress changeImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesLinear motionStructural engineering

The invention provides a double-spot double-face floating welding gun which comprises a first single spot welding mechanism, a second single spot welding mechanism and a linear motion assembly, and the first single spot welding mechanism and the second single spot welding mechanism are installed in a matched mode through the linear motion assembly. The welding gun has the beneficial effects that the two single spot welding mechanisms are connected through the linear motion assembly, two positions can be welded at the same time, the problem that stress changes are generated due to the fact that the two spots are not welded at the same time is solved, the welding precision and the working efficiency are improved, the distance between the two welding positions can be adjusted by adjusting the linear motion assembly, and the welding gun can be suitable for more working scenes.

Owner:天津七所高科技有限公司

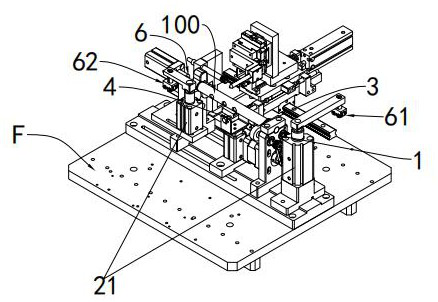

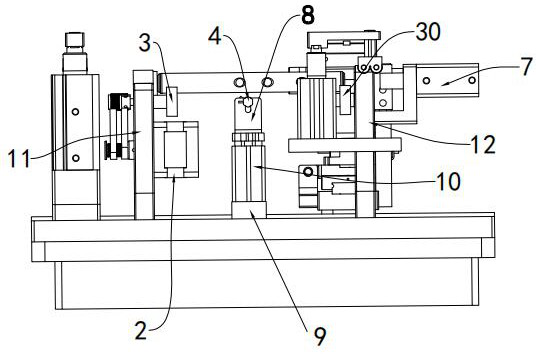

Positioning device for gearbox shift fork shaft

ActiveCN114012635BEasy to detectReduce distractionsWork holdersUsing optical meansControl engineeringElectric machinery

The invention discloses a positioning device for a shift fork shaft of a gearbox, which comprises a support seat for resting the shift fork shaft, and the shift fork shaft can rotate around its axis on the support seat; The motor and the roller group in contact with the shaft surface of the shift fork shaft, the motor drives the roller group to drive the shift fork shaft to rotate; a detection sensor with a fixed position is used to detect whether the shift fork hole of the shift fork shaft is at the preset orientation position. When the fork shaft rotates, when the detection sensor detects that the fork hole of the fork shaft is in a preset orientation, the motor stops rotating so that the fork shaft stops rotating; a positioning component includes a fixed limiting wall and a movable top One end face of the shift fork shaft is pressed against the limiting wall, and the other end face of the shift fork shaft is pressed tightly by the top contact at the stop position.

Owner:IKD CO LTD

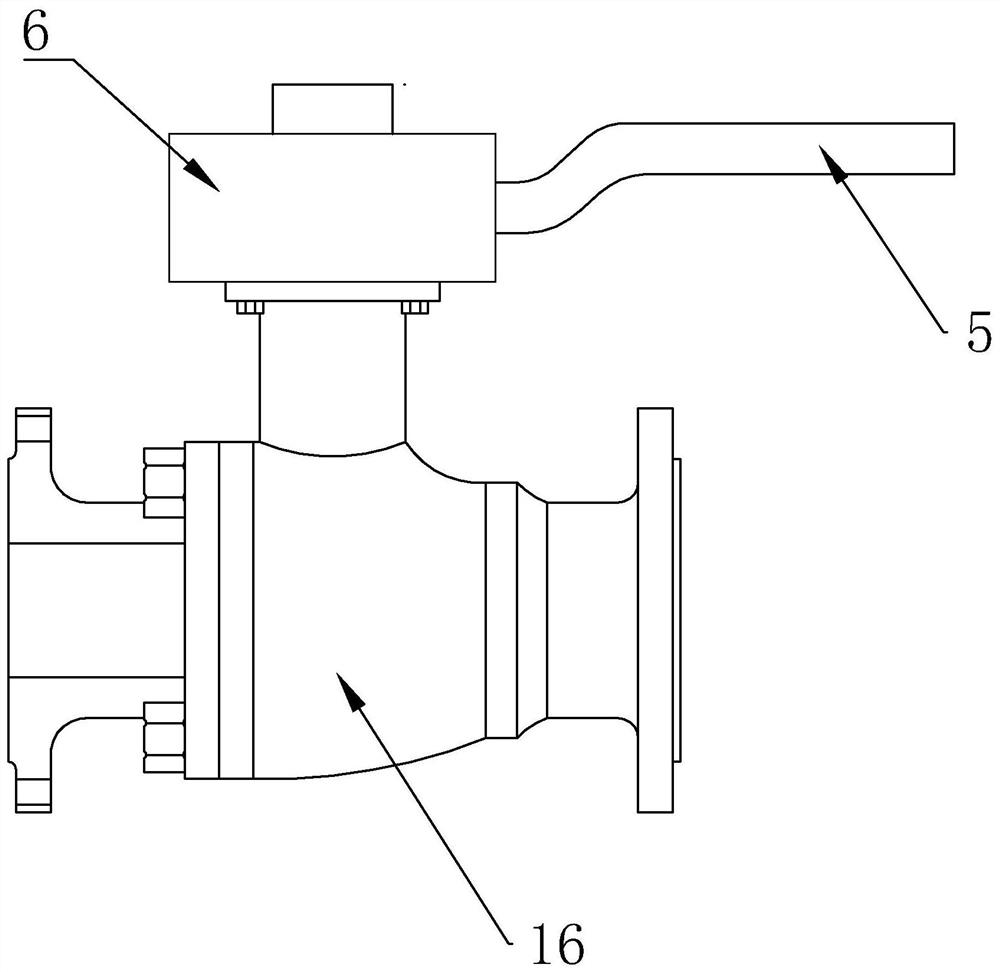

A spool, valve and method using the spool

ActiveCN112212027BQuick closeTurn fasterPlug valvesOperating means/releasing devices for valvesGear wheelEngineering

The invention discloses a valve core, a valve using the valve core and a method thereof. The valve core includes a valve ball, a transmission rod, a damping gear and a steering clamping device. One end of the transmission rod is connected to the valve ball, and the other end is connected to the damping gear. , the valve includes a valve body, a casing and a joystick, the casing is installed on one side of the valve body, the bottom end of the joystick protrudes into the casing, and one end of the transmission rod is also placed in the casing, and is flexibly connected with the joystick. When the lever swings clockwise, the resistance is provided by the damping gear, so that the instantaneous swing range of the joystick is low, which is convenient for adjusting the flow rate. When the flow rate is directly adjusted from off to maximum, just swing the joystick counterclockwise. 0‑±90°, easy to adjust and high efficiency.

Owner:WENZHOU ZHENHONG VALVE BALL CO LTD

Novel sealing element

InactiveCN104154230AIncrease radial frictionPrevent radial rotationEngine sealsMechanical engineeringEngineering

Owner:宁波浙成科技有限公司

Contact piece and connector

PendingCN112821106AReduce processing difficultyPrevent radial rotationSecuring/insulating coupling contact membersSoldered/welded conductive connectionsInterference fitOrganic solvent

The invention provides a contact piece and a connector. The contact piece comprises a body, two circles of supporting thorns are arranged on the outer wall of the body at intervals, the supporting thorns surround the outer wall of the body by a circle to form a complete and continuous whole, and when the contact piece is installed in a base of the connector, the supporting thorns are in elastic interference fit with the base. The contact piece and the connector have a certain effect of preventing radial rotation of the contact piece, have a function of blocking flow of an organic solvent, protect a butt joint end from being polluted, and ensure reliability of electric connection.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Bending Bike Tube Rack for Battery Storage

InactiveCN108068964BPrevent radial rotationEasy to installOptical signalCycle framesElectrical batteryClassical mechanics

The invention provides a bicycle pipe support capable of accommodating a battery and being bent. The bicycle pipe support capable of accommodating the battery and being bent comprises a front pipe support, a rear pipe support, a bending assembly and a battery, wherein the bending assembly is used for pivoting the front pipe support and the rear pipe support; a front accommodating groove is arranged to extend inwards in the axial direction of the front pipe support; the front accommodating groove is used for accommodating a controller; a rear accommodating groove is arranged to extend inwards in the axial direction of the rear pipe support; the axial length of the front pipe support is 1 / 6-1 / 3 of the length of the rear pipe support; and the battery is accommodated within the rear accommodating groove of the rear pipe support and is electrically connected with the controller.

Owner:LEKUMA ENERGY TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com