Underwater natural gas pipeline leakage automatic plugging robot and using method thereof

A technology of natural gas pipelines and robots, applied in the direction of manipulators, pipe components, mechanical equipment, etc., can solve problems such as pipeline damage, economic loss, and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

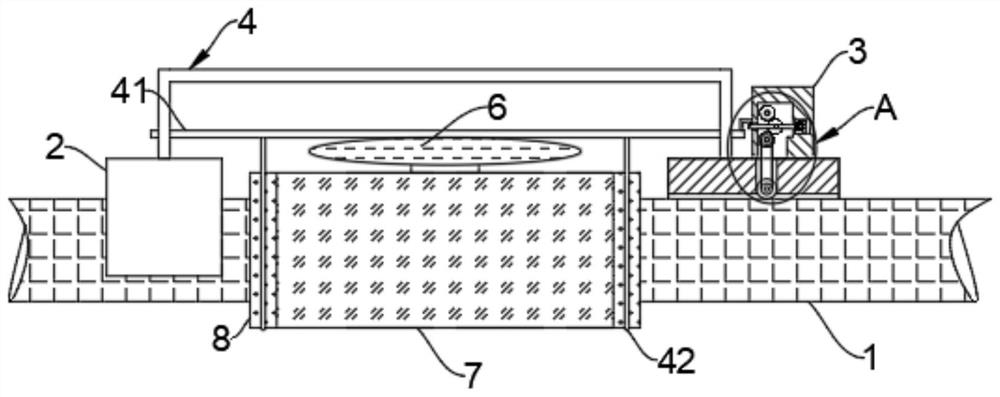

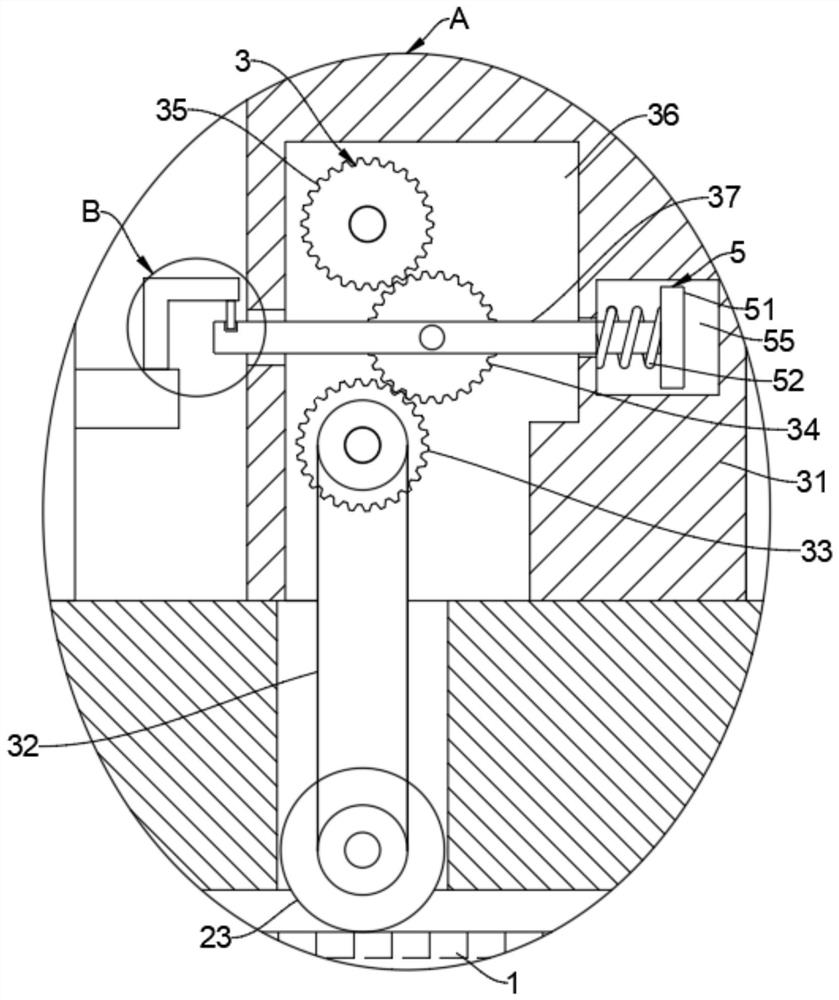

[0033] Such as Figure 1-5 As shown, an underwater natural gas pipeline leakage automatic sealing robot and its use method include a support mechanism 2 connected with a pipeline 1, such as Figure 4 As shown, the support mechanism 2 is composed of a fixed cylinder 21 , a fixed wheel 22 and a support wheel 23 .

[0034] The section of the fixing cylinder 21 is a 2 / 3 arc structure, and the fixing cylinder 21 has a three-section hinge structure, so that the fixing cylinder 21 can be conveniently fixed on the pipeline 1 .

[0035] The fixed wheel 22 is rotatably connected to both sides of the fixed cylinder 21 and is rollingly connected with the pipeline 1 along the axial direction of the pipeline 1. The supporting wheel 23 is located at the top of the pipeline 1 and is rollingly connected with the pipeline 1 along the axial direction of the pipeline 1. 21 turn to connect.

[0036] Both the support wheel 23 and the fixed wheel 22 can ensure that the support mechanism 2 can easily...

Embodiment 2

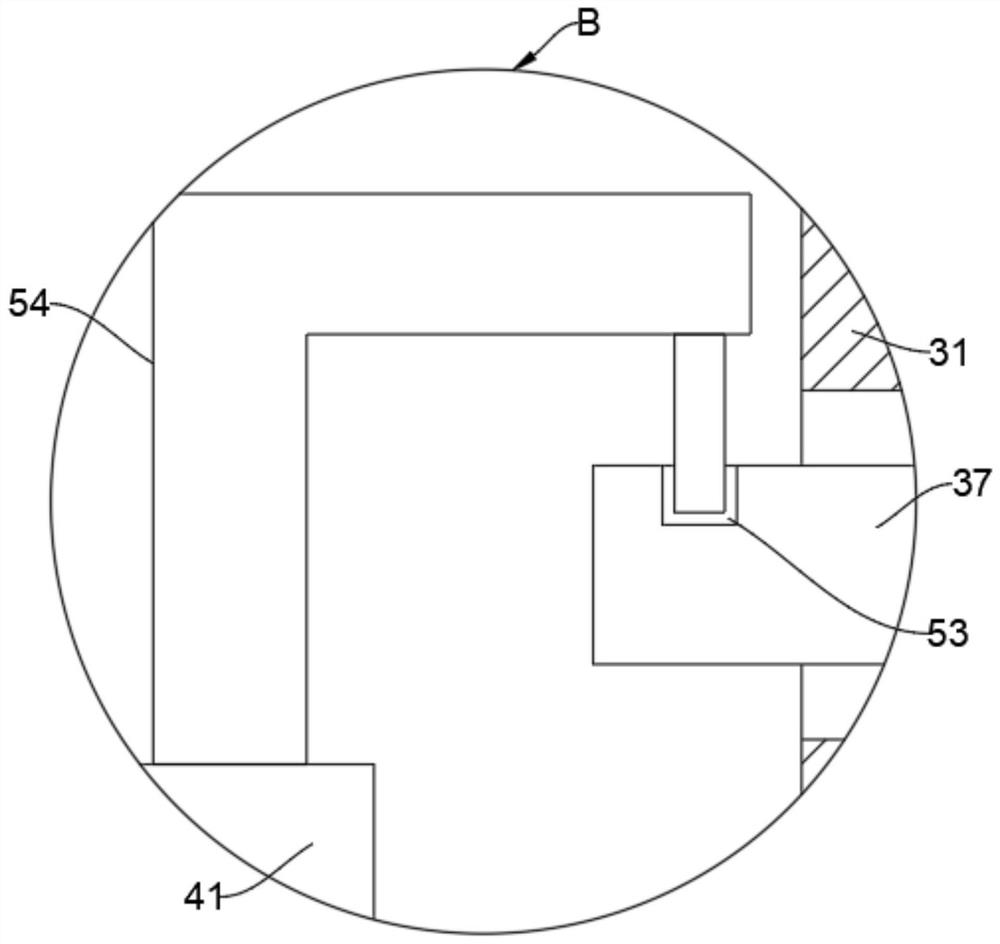

[0052] Such as Figure 6-7 As shown, the difference between this embodiment and Embodiment 1 is that: a vertical rack 43 is fixedly connected to the top of the support mechanism 2, the rack 43 is fixedly connected to the connector 4, and the sliding rod 37 is rotatably connected to a rotating cylinder 44 , the rotating cylinder 44 is fixedly connected with a rotating gear 45 and a take-up wheel 46 , and the take-up wheel 46 is fixedly connected with the stay cord 42 .

[0053] And then realize that when the sliding bar 37 slides upwards, the rotating gear 45 cooperates with the tooth bar 43 and then can realize that the rotating gear 45 drives the rotating cylinder 44 to rotate, and then realizes that the rotating cylinder 44 drives the take-up pulley 46 fixedly connected therewith to rotate, and the take-up The wheel 46 has a larger diameter, and then it can be realized that when the sliding rod 37 slides a certain distance, the take-up wheel 46 will make the pulling distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com