Trailer

A sub-frame and suspension technology, which is applied in the direction of motor vehicles, vehicle parts, traction connectors, etc., can solve the problems of large volume, high center of gravity, poor stability, etc., and achieve more energy storage, reliable connection, and stable maintenance running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

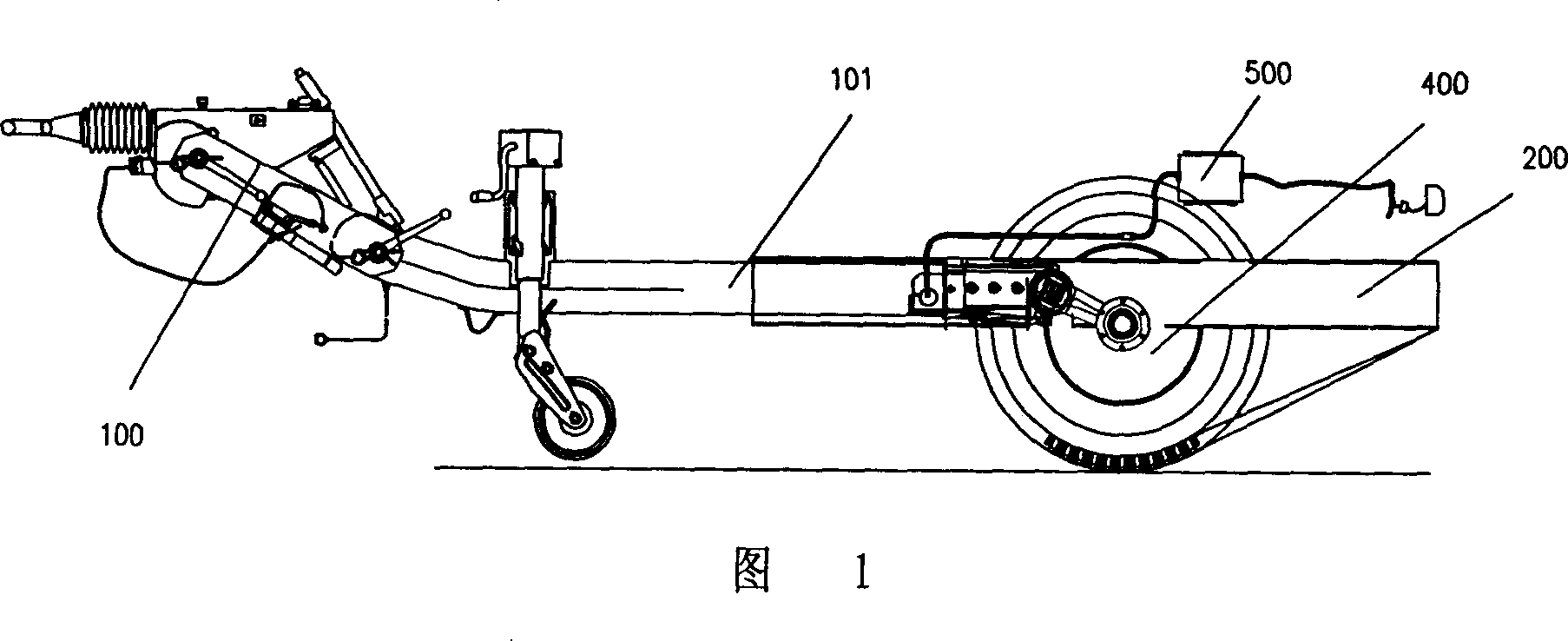

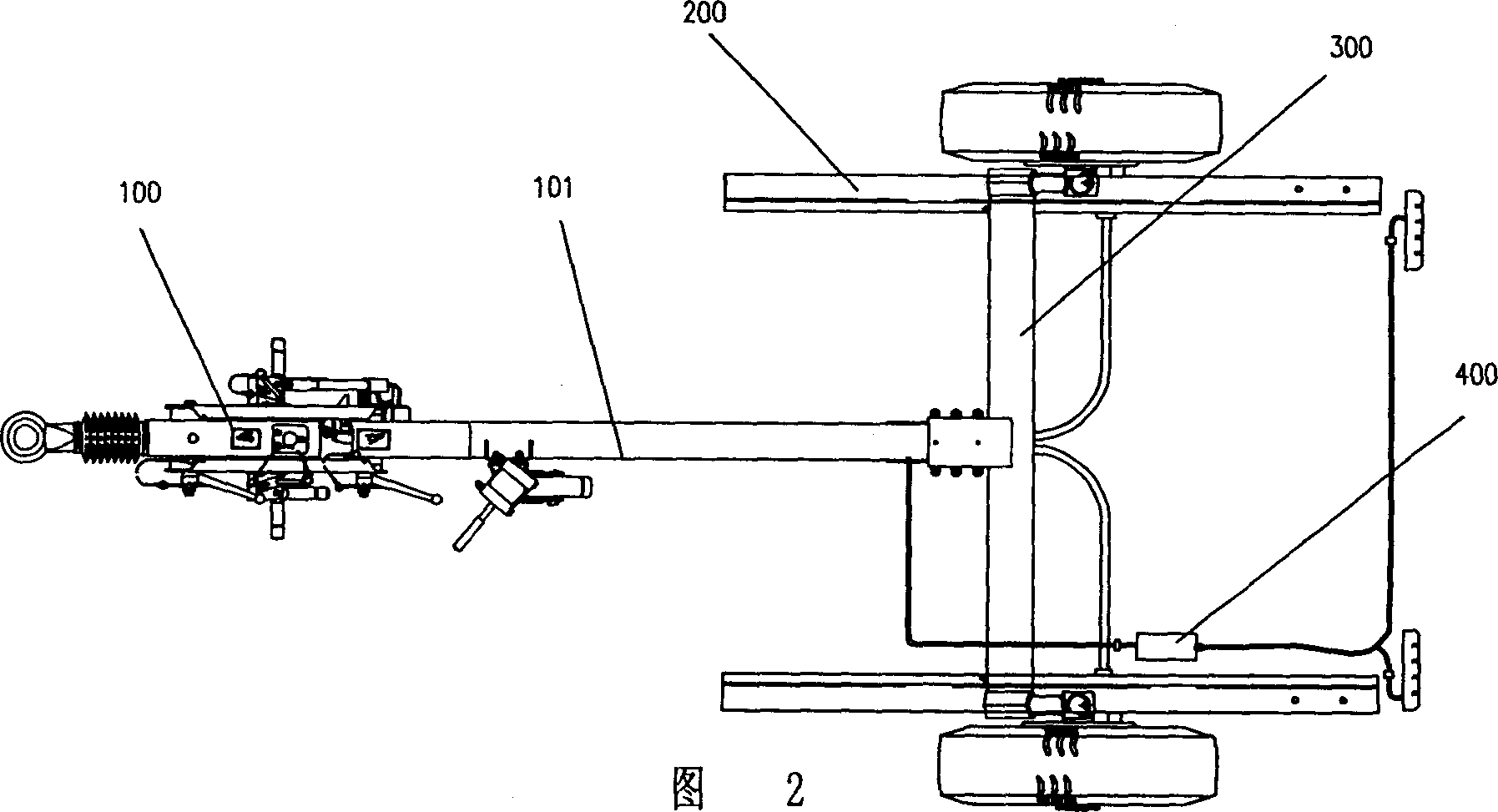

[0025] As shown in FIGS. 1 and 2 , the trailer of the present invention mainly includes a tractor head 100 , a subframe 200 , a suspension device 300 , a braking device 400 and a taillight system 500 .

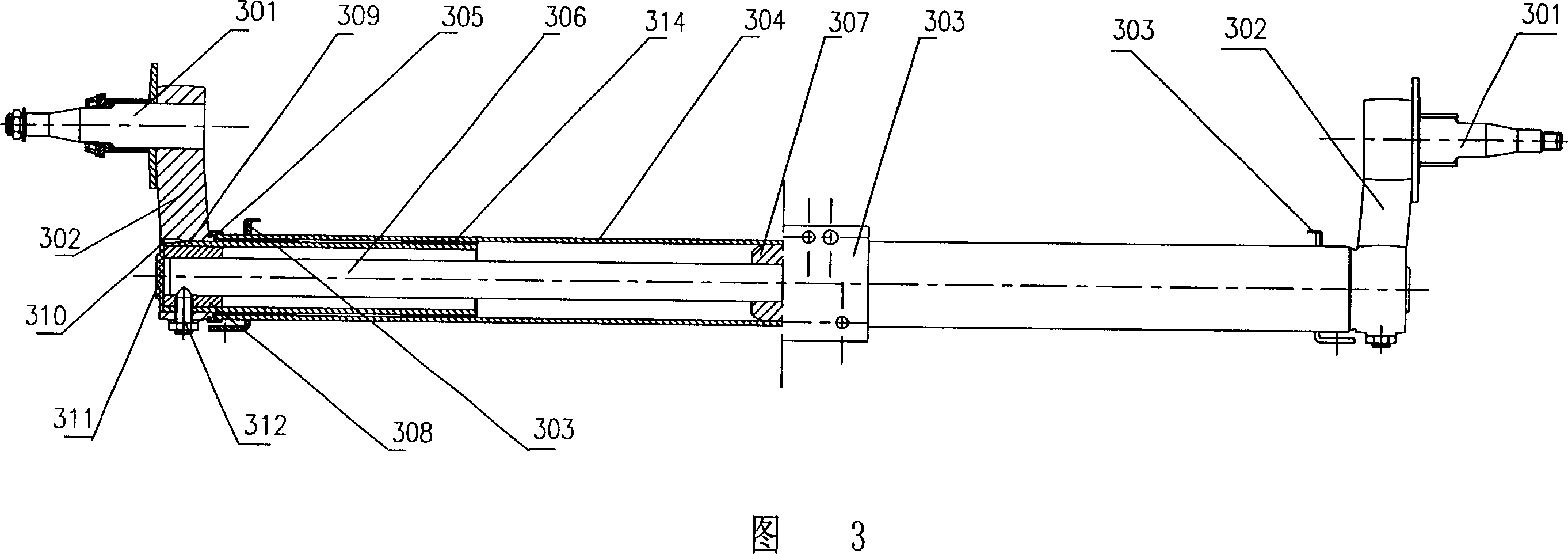

[0026]As shown in Figures 3 to 5, the suspension system 300 of the present invention includes two tire axles 301 arranged on both sides of the sub-frame 200, a balance arm 302 is respectively fixed on the two tire axles 301, and a balance arm 302 is respectively fixed at the bottom of the two balance arms 302. A hanging piercing hole is provided. A suspension beam 303 is fixed on the sub-frame, and the center of the suspension beam 303 is connected with the traction beam 101 of the traction head 100 through a connecting device 304 . A sealing and lubricating device 305 including a sealing ring is provided at the connection between the suspension beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com