A spool, valve and method using the spool

A valve core and valve technology, applied in valve operation/release devices, valve details, valve devices, etc., can solve the problem of impurities or microorganisms entering between the valve ball and the valve body, accelerating the wear of the valve ball and the inner wall of the valve, Reduce the problem of sealing, achieve the effect of convenient precise control, avoid misoperation, and facilitate the flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further description will be made with reference to the embodiments of the present invention.

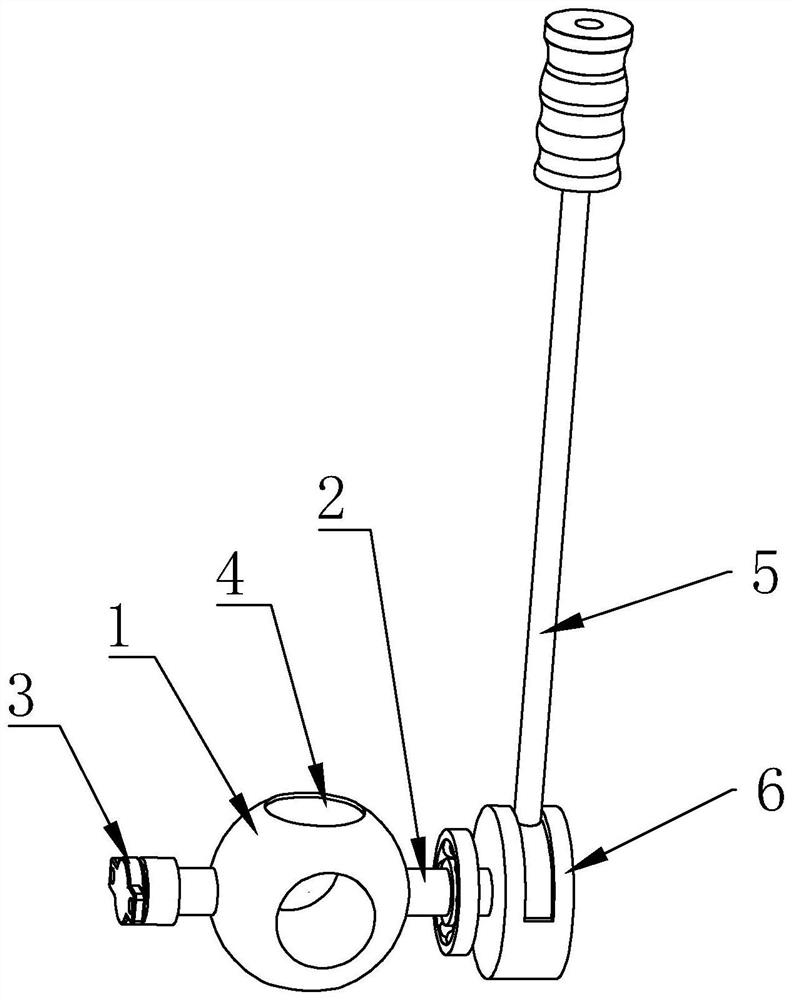

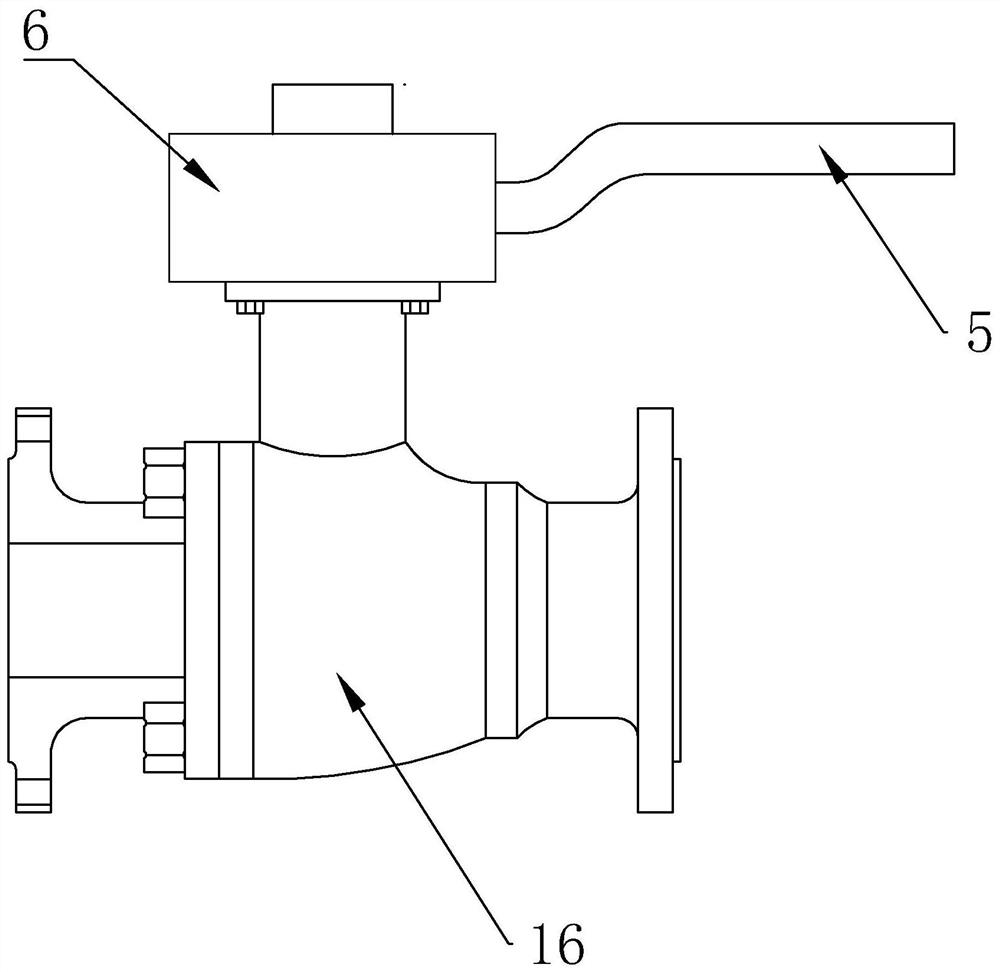

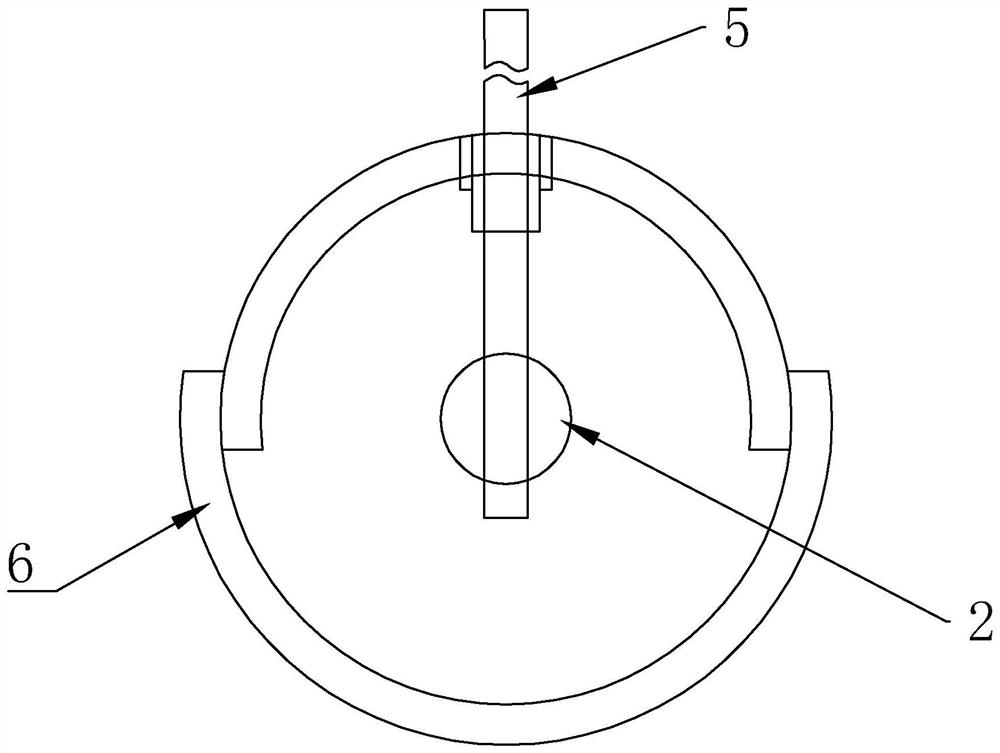

[0030] according to figure 1 As shown, the valve core is composed of a valve ball 1, a transmission rod 2, a damping gear 3 and a steering clamping device. The through hole on the valve ball 1 runs through the center of the ball. The other end of the valve is fixedly connected with the gear seat, the internal gear is installed in the gear seat, the damping gear 3 is connected with the internal gear, the through hole on the valve ball 1 and the transmission rod 2 are vertically arranged on the same horizontal plane, and the outer surface of the valve ball 1 There is a blind hole 4 on the top, and the blind hole 4 and the through hole are vertically arranged on the same horizontal plane. The inner diameter of the blind hole 4 is the same as that of the through hole, and there are two blind holes 4. , when the fluid in the valve is water or petroleum, microorganisms are likely t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com