CRTS (China Railway Track System) II type track plate pavement video sensing mechanism

A technology of video sensing and video sensor, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of difficult to realize automatic operation, difficult to realize automation, slow adjustment speed, etc., to achieve reasonable design, high degree of automation, precision The effect of positioning and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

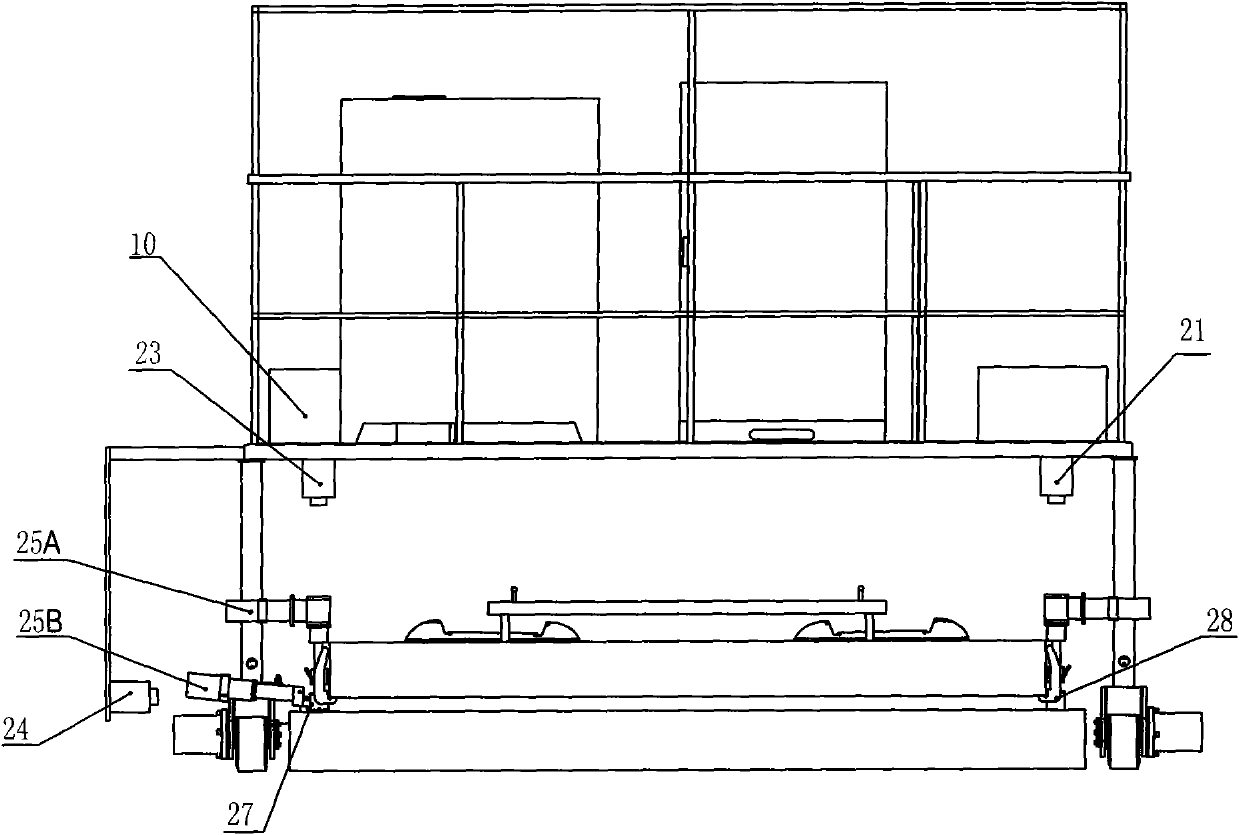

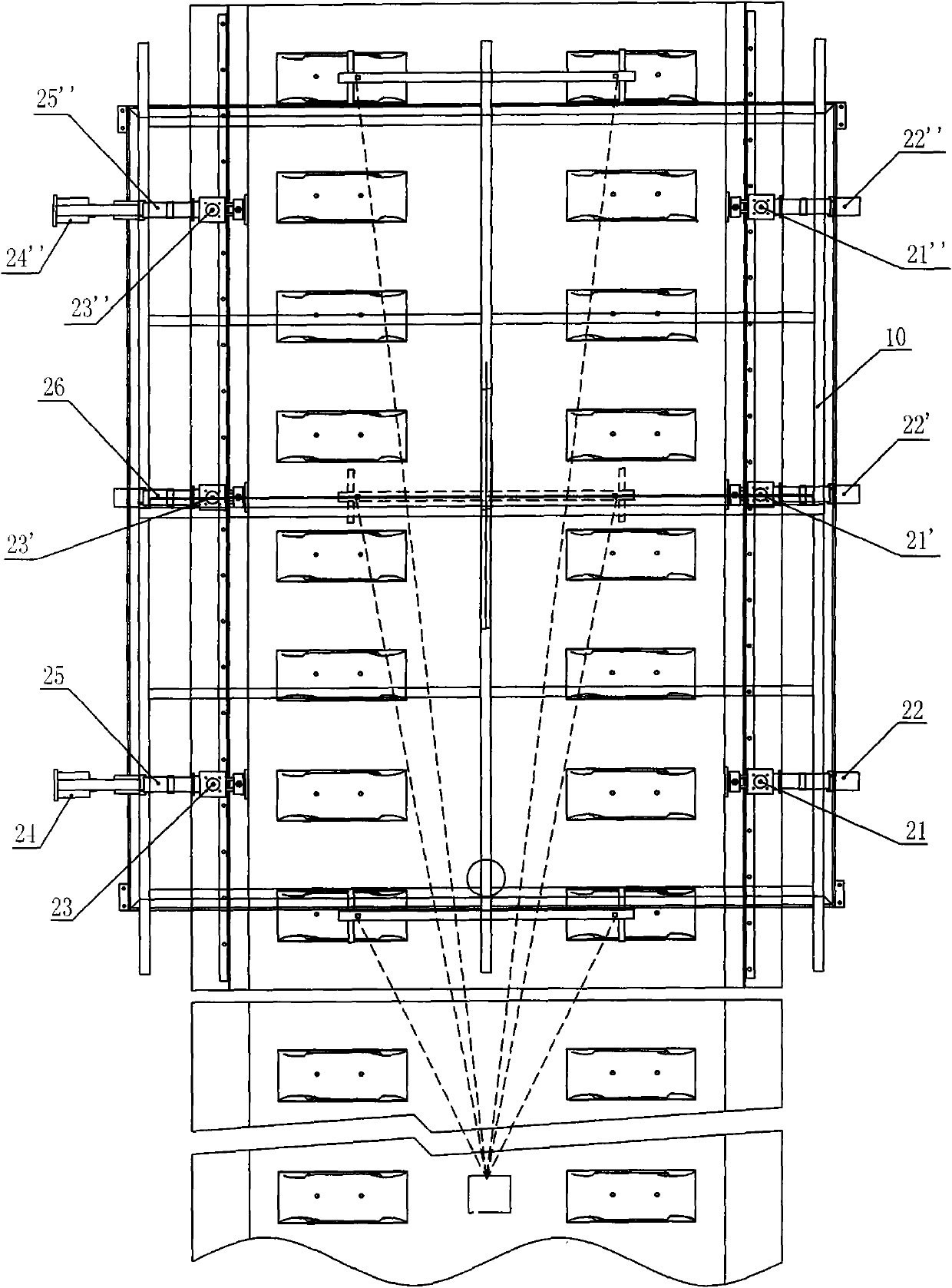

[0019] Such as figure 1 and figure 2 As shown, the CRTS II type track slab laying video sensing mechanism is set on the fine-tuning vehicle 10, which is composed of six sets of video acquisition devices, and the six sets of video acquisition devices are respectively set corresponding to the six sets of fine-tuning mechanisms. The video sensing mechanism is respectively arranged on both sides of the fine-tuning car 10, and one side of the fine-tuning car is provided with three vertical video sensors 23, 23', 23" and two horizontal video sensors 24, 24", The other side of the fine-tuning vehicle is provided with three vertical video sensors 21, 21', 21".

[0020] One side of the fine-tuning vehicle is provided with three groups of video acquisition devices, wherein two groups of video acquisition devices are composed of a horizontal video sensor and a vertical video sensor, which are respectively used to monitor the vertical and horizontal fine-tuning mechanisms 25, 25 "; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com