Heat exchanger

A heat exchanger and fin technology, which is applied in the field of heat exchangers, can solve the problems of accumulation of frost layer and reduce the heat exchange capacity of heat exchangers, and achieve the effect of delaying frost formation and ensuring performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

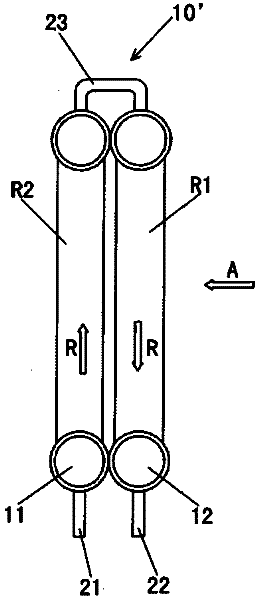

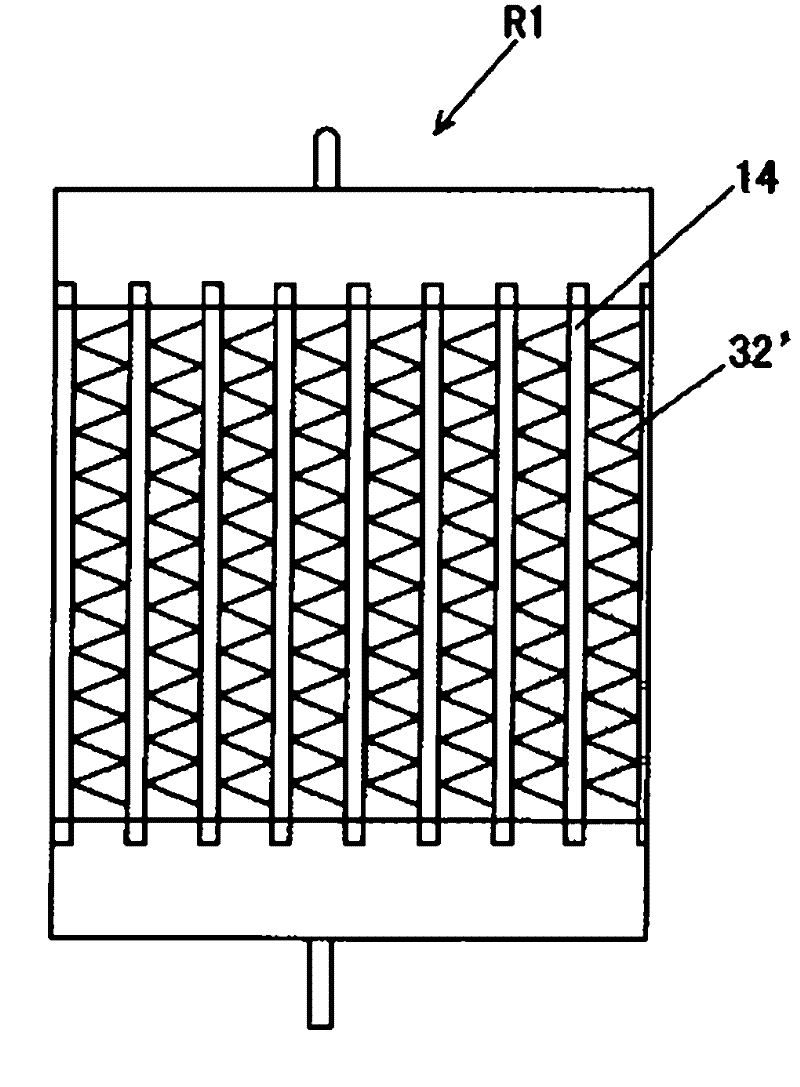

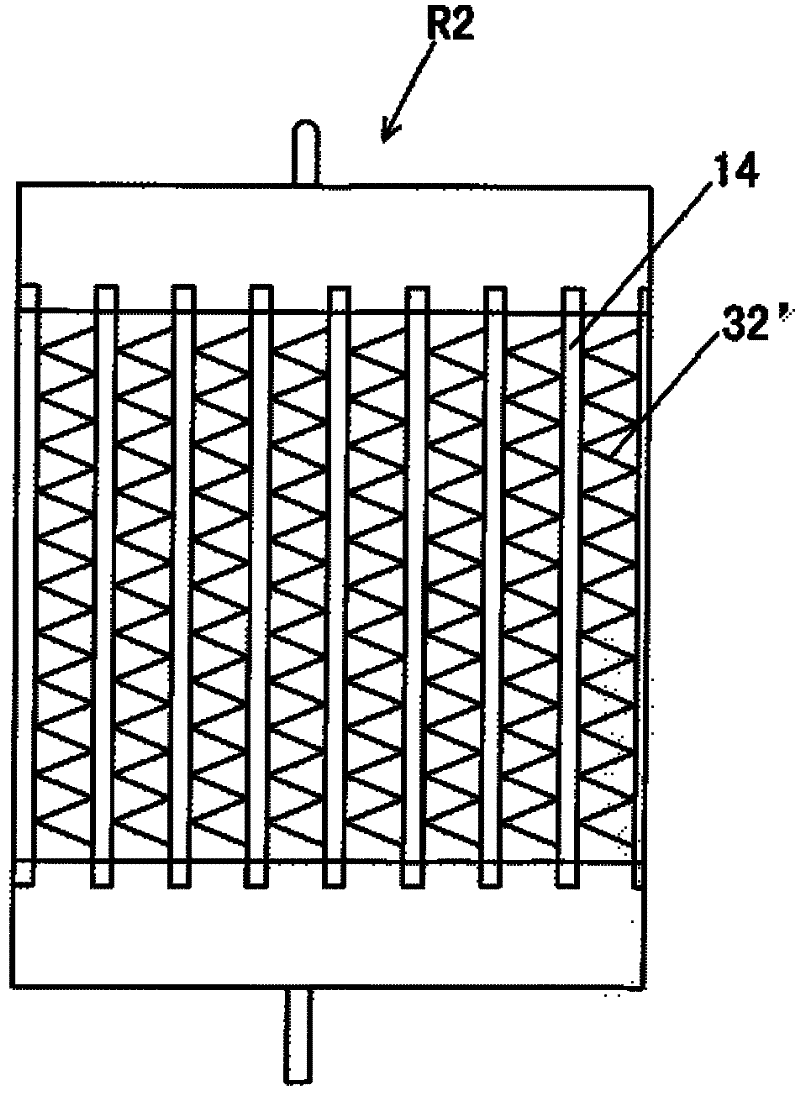

[0028] Figure 2A , 2B , 2C, 3A, 3B, 3C show a heat exchanger according to a first embodiment of the present invention. refer to Figure 2A , 2B , 2C, 3A, 3B, 3C, the heat exchanger 10 according to an embodiment of the present invention may be a microchannel heat exchanger, and includes: a first row of heat exchangers R1 and a second row of heat exchangers R2 arranged side by side, The first row of heat exchangers R1 includes fins 32 and the second row of heat exchangers R2 includes fins 34, the fin density of the fins 32 of the first row of heat exchangers R1 is the same as that of the fins of the second row of heat exchangers R1. different fin densities. Fin density is the number of half crests of corrugated fins per inch of length, and the definition of this term is common knowledge in the art.

[0029] The heat exchanger 10 also includes: a header 11 at the inlet end of the heat exchanger and a header 12 at the outlet end of the heat exchanger, which are respectively ...

Embodiment 2

[0034] Figure 4A , 4B , 4C, 4D, 5A, 5B, 5C, 5D, 6A, 6B, 6C, 6D show a heat exchanger according to a second embodiment of the present invention. refer to Figure 4A , 4B , 4C, 4D, 5A, 5B, 5C, 5D, 6A, 6B, 6C, 6D, the heat exchanger 10 according to an embodiment of the present invention may be a microchannel heat exchanger, and includes: a first row arranged side by side Heater R1, the second row of heat exchangers R2 and the third row of heat exchangers R3, the first row of heat exchangers R1 includes fins 32, the second row of heat exchangers R2 includes fins 34, the third row of heat exchangers R1 includes fins 36, the fin density of the fins 32 of the first row of heat exchangers R1, the fin density of the fins 34 of the second row of heat exchangers R2, and the fins of the third row of heat exchangers R3 At least two of the 36 fin densities are different. The second row of heat exchangers R2 is disposed between the first row of heat exchangers R1 and the third row of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com