Holder stay fixing structure and motor with brush

A support plate and structure technology, which is applied in the field of live brush motors, can solve problems such as support support plate damage, and achieve the effect of improving assembly workability and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

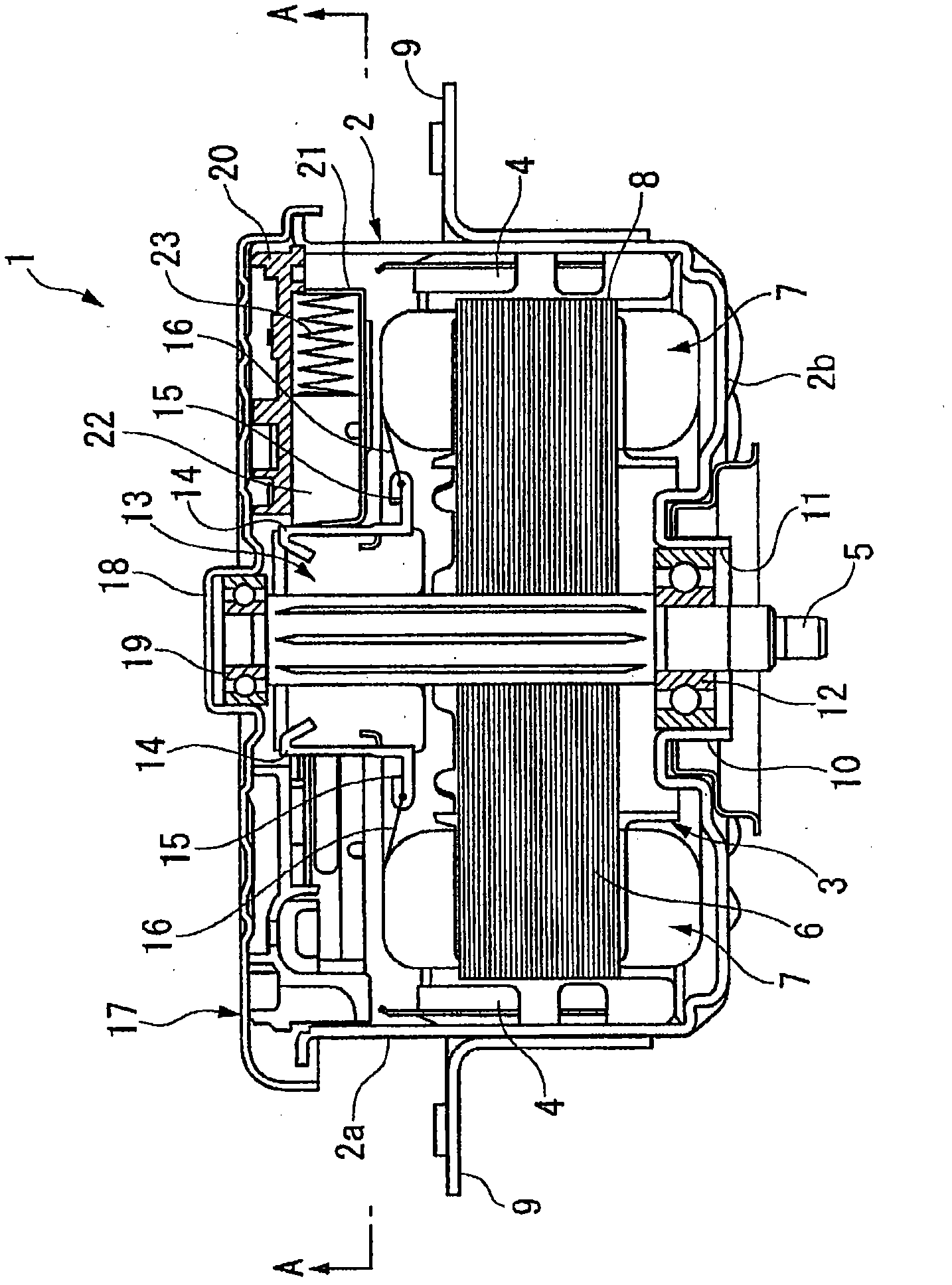

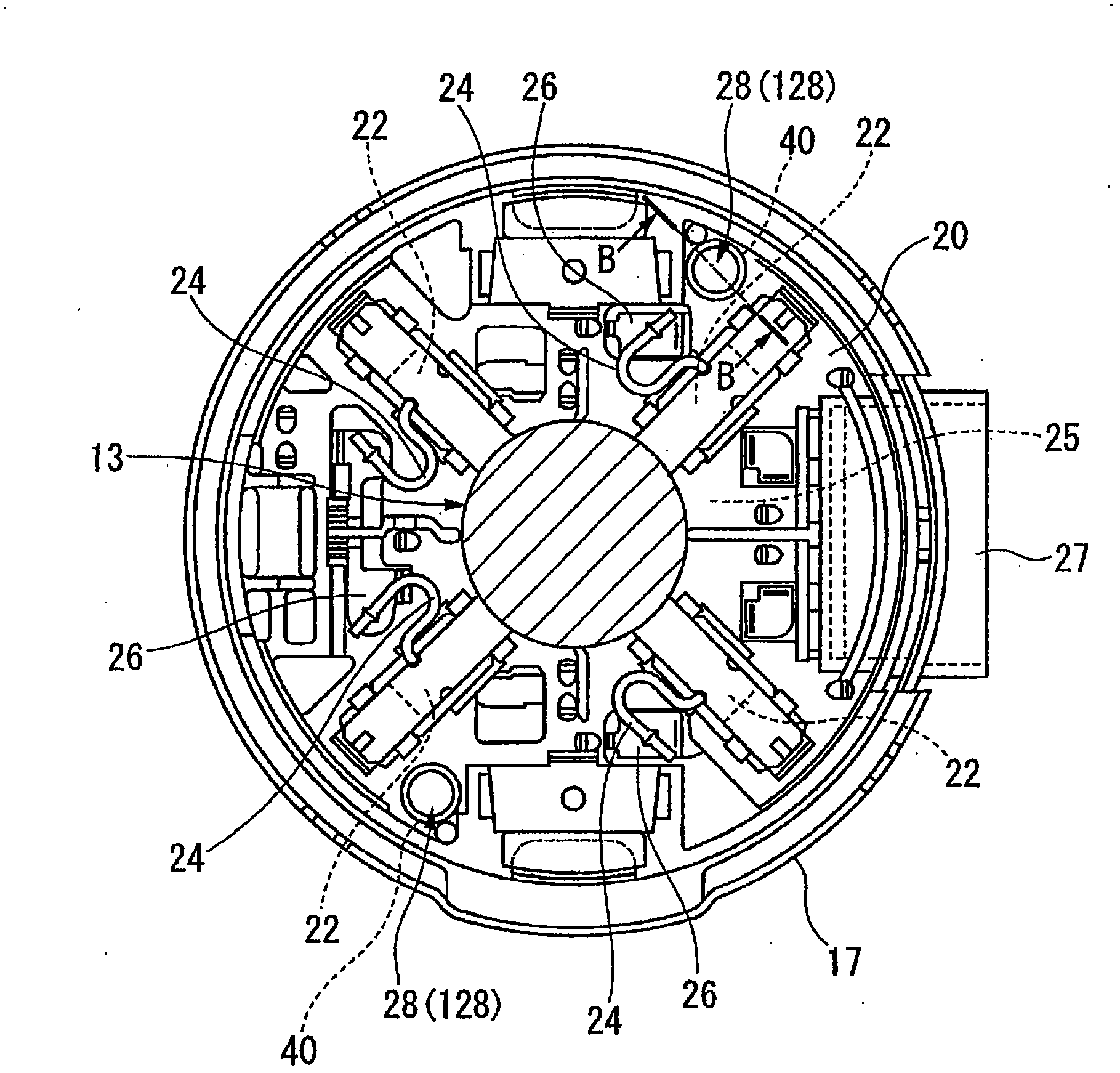

[0048] Such as figure 1 as well as figure 2 As shown, the brushed motor 1 is a driving source of an electric product (for example, a radiator fan) mounted on a vehicle. The brushed motor 1 has an armature 3 rotatably provided in a bottomed cylindrical yoke 2 , and an opening 2 c of the yoke 2 is closed by an end bracket 17 .

[0049] A support plate 9 used to fix the brushed motor 1 outside protrudes from the peripheral wall 2 a of the yoke 2 , while a plurality of permanent magnets 4 are juxtaposed along the peripheral direction inside the peripheral wall 2 a. In addition, a boss portion 10 is formed at an approximate center in the radial direction at an end portion (bottom portion) 2 b of the yoke portion 2 . In this boss portion 10 , an insertion hole 11 through which the rotating shaft 5 of the armature 3 is inserted is formed, and a bearing 12 for rotatably supporting one end side of the rotating shaft 5 is incorporated therein.

[0050] The armature 3 includes an arm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap