Drill assembly and system and method for forming a pilot hole

A drilling machine and component technology, used in bone drill guidance, medical science, surgery, etc., can solve the problems of unsatisfactory, expensive, and complicated technology, and achieve the effect of reasonable cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the invention described below are not intended to be exhaustive or to limit the invention to the precise forms disclosed in the following detailed description. Rather, these embodiments were chosen and described so that others skilled in the art can appreciate and understand the principles and practice of the invention.

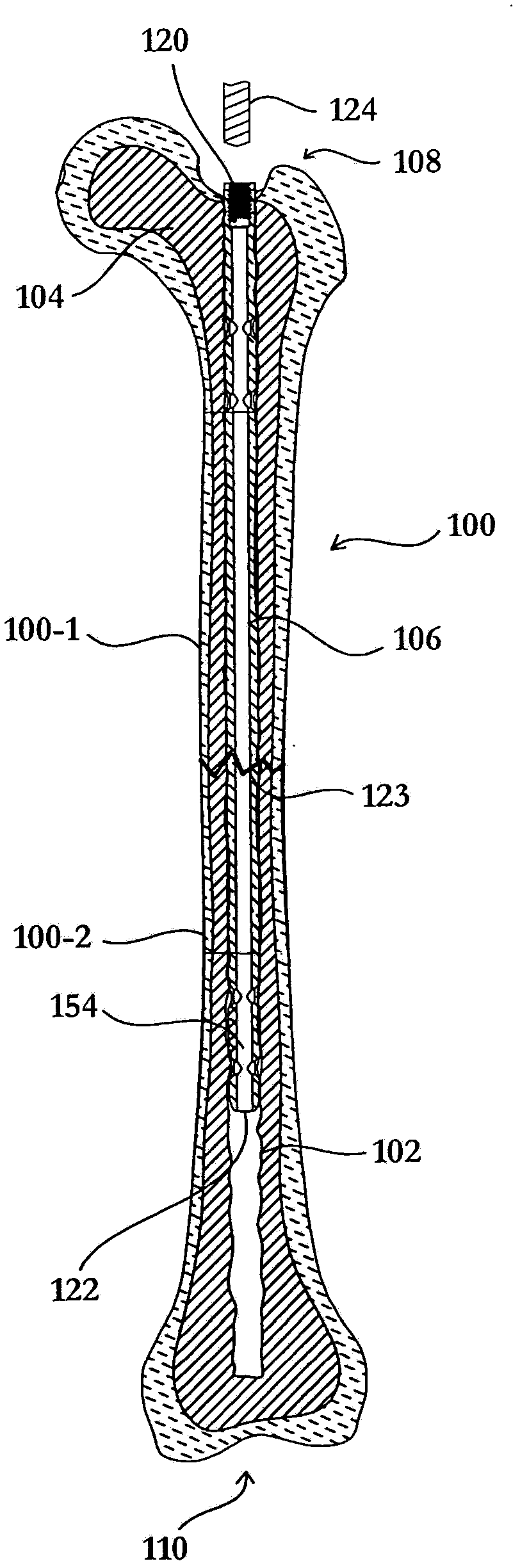

[0030] Referring now to the drawings, wherein like reference numerals are used to designate these parts throughout the drawings, first reference figure 1 , shows a cross-sectional view of two portions 100-1 and 100-2 of a fractured femur. Although the fracture is generally shown as a neat break 123 in both parts of the bone, the femur 100 may also be broken into many smaller bone pieces or damaged in some other way. Therefore, it should be understood that the devices and methods described herein for two bone blocks can also be applied to three or more bone blocks or bone fragments, or even broken bones that have not been divided int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com