Rectangular battery

A technology for square batteries and battery shells, which is applied in the manufacture of batteries, secondary batteries, and secondary batteries. It can solve the problem of no contribution to battery power generation and achieve high capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

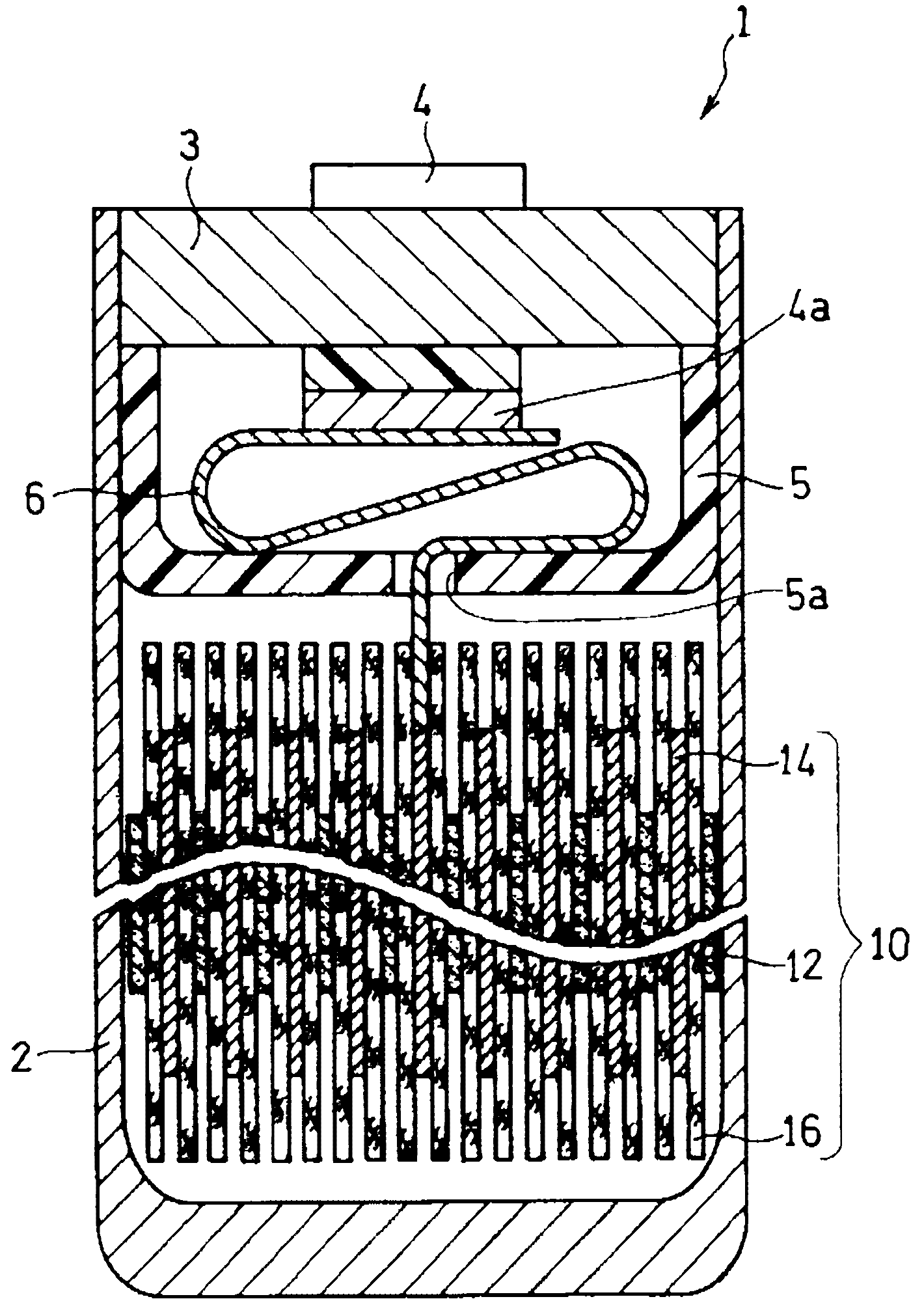

Embodiment 1

[0067] (1) Production of positive electrode

[0068] A positive electrode was prepared in the following order.

[0069] The positive active material (LiNi 0.8 co 0.15 Al 0.05 o 2 ), acetylene black as a conductive agent, and PVdF (PolyVinylidene Fluoride: polyvinylidene fluoride) as a binder are mixed in a weight ratio of 90:5:5, and NMP (N-formazan) is added as a dispersant base pyrrolidone) while stirring with a double-arm mixer. In this way, positive electrode slurry was prepared.

[0070] This positive electrode slurry was applied to both surfaces of a positive electrode core material (current collector) formed of an aluminum foil having a thickness of 15 μm. It was dried in an atmosphere of 120° C. to remove NMP, rolled to a thickness of 115 μm (the thickness of one side of the positive electrode active material layer was 50 μm) with a roll press, and cut into a predetermined size to produce a positive electrode. The thickness of the positive electrode core materia...

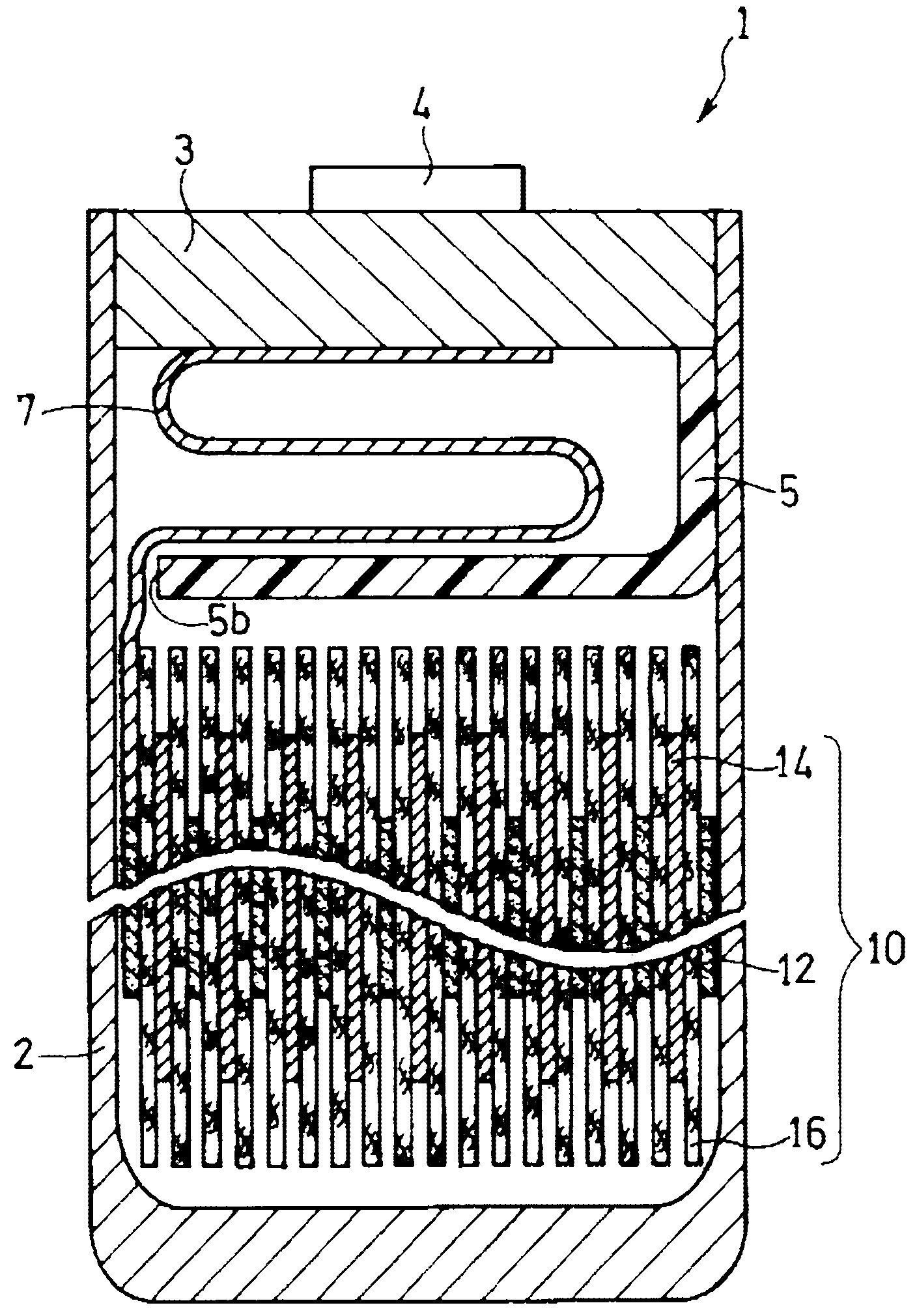

Embodiment 2

[0088] In addition to the length L1 (refer to Figure 4 ) was set to 0.5 mm, and five lithium ion secondary batteries were produced in the same manner as in Example 1.

Embodiment 3

[0090] In addition to the length L1 (refer to Figure 4 ) was set to 2.5 mm, and five lithium ion secondary batteries were produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com