Rolled copper foil for secondary battery negative electrode current collectors, secondary battery negative electrode current collector and secondary battery each using same, and method for manufacturing rolled copper foil for secondary battery negative electrode current collectors

A negative electrode current collector and secondary battery technology, applied in the field of rolled copper foil, can solve the problems of poor cycle characteristics and falling off of active materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Next, the rolled copper foil of the present invention was manufactured in an attempt, and the performance thereof was confirmed, which will be described below. However, the description here is for the purpose of illustration only, and is not intended to be limited thereto.

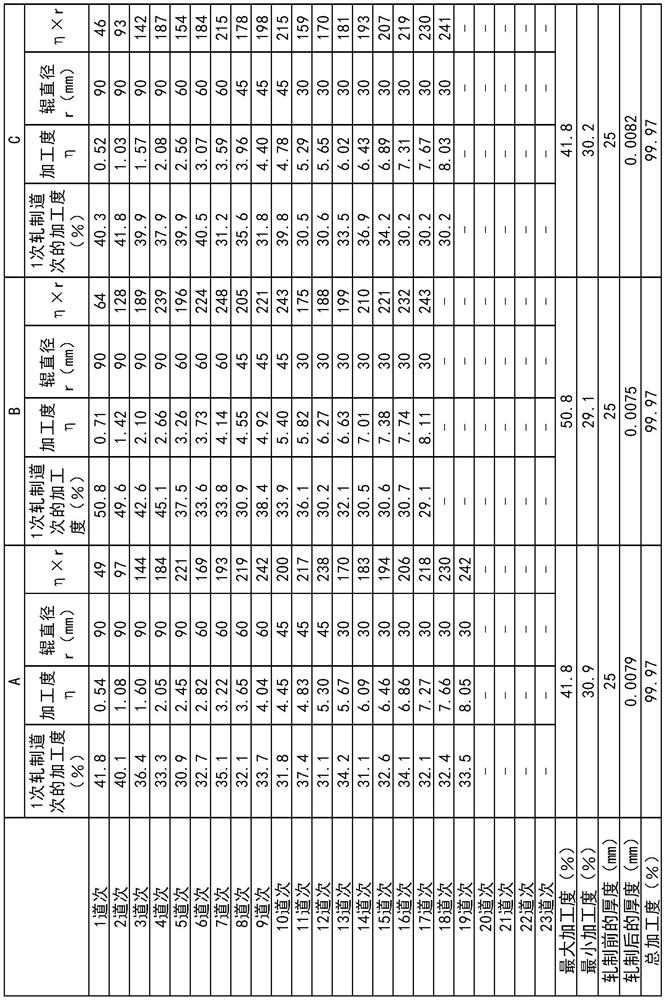

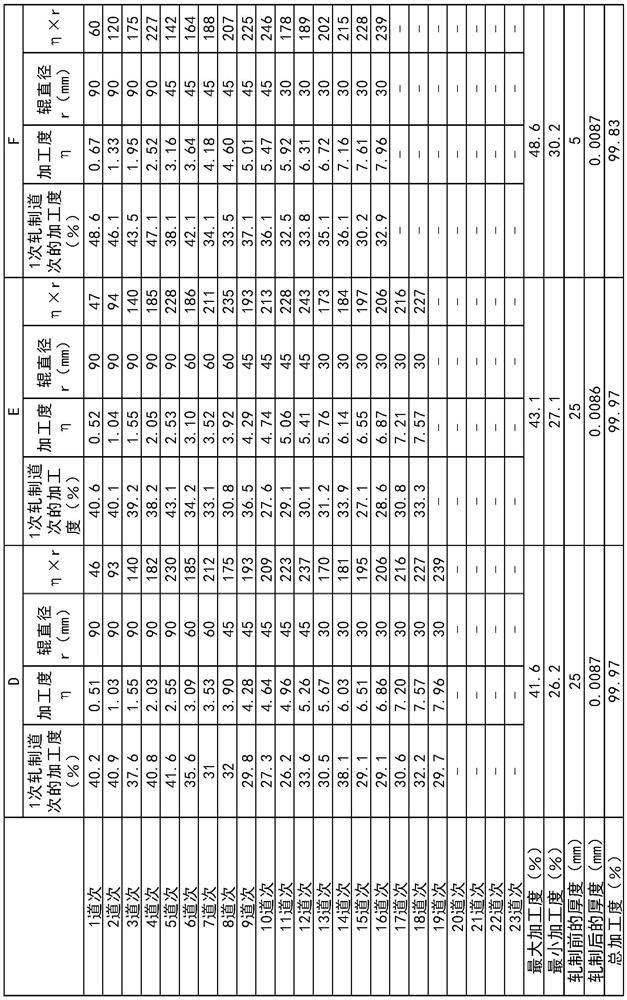

[0059] First, an ingot having a composition of Cu-0.20% by mass Sn was melt-produced, and the ingot was hot-rolled from 900° C. to obtain a plate with a thickness of 100 mm. Thereafter, a rolled copper foil having a thickness of 10 μm was finally obtained through the final cold rolling process under the conditions of each pass of A to I shown as an example in Table 1. "-" in the table means no processing.

[0060] The following characteristic evaluations were performed on each of the test pieces thus obtained. The results are shown in Table 2.

[0061]

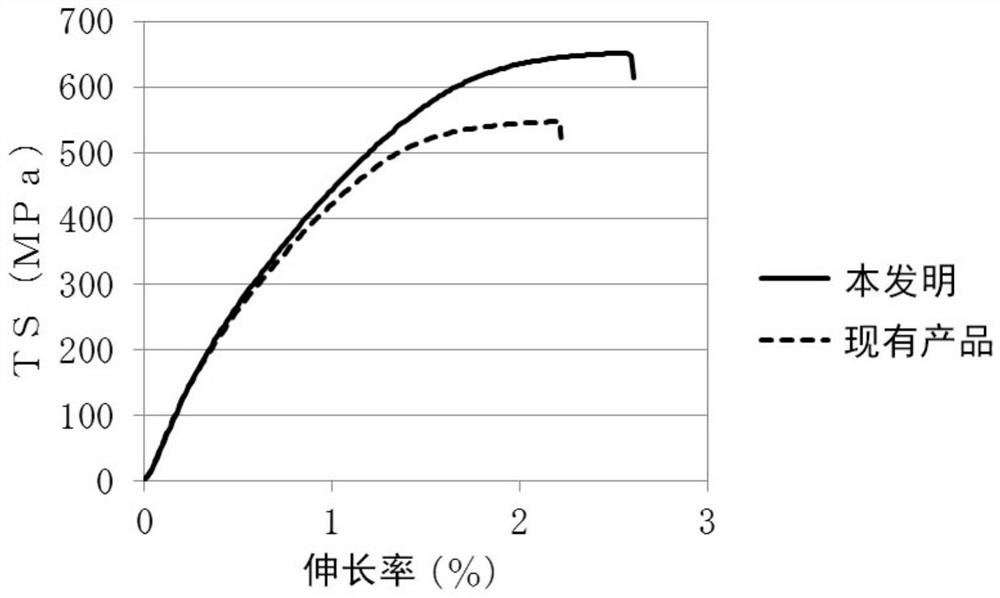

[0062] Make a test piece with a length of 100 mm and a width of 12.7 mm, and perform a tensile test using a tensile testing machine parallel t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com