Variable speed horizontal elevator mechanical system

A mechanical system and elevator technology, applied in escalators, transportation and packaging, etc., can solve problems such as insecurity, large speed changes, and inability to save time, and achieve the effect of taking into account both rapidity and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1. The basic structure of the elevator

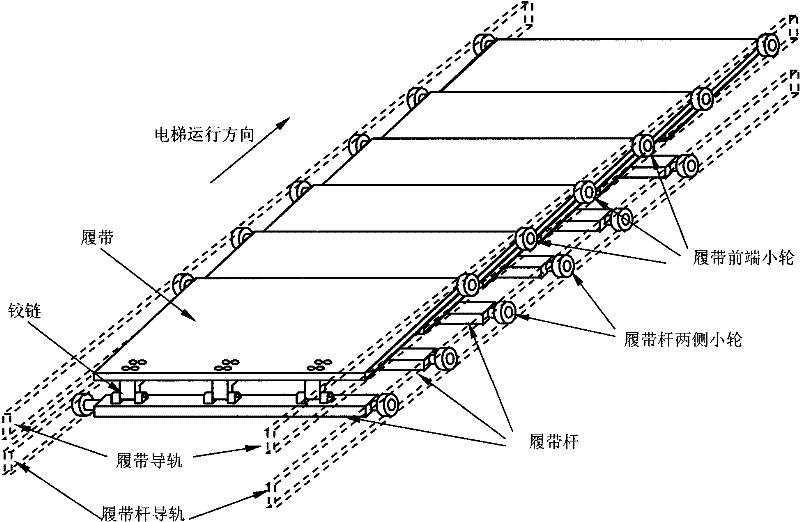

[0017] The crawler belt of the elevator is formed by stacking many pieces of crawler belts one by one along the speed direction of the elevator, and the latter one is pressed on the previous one. The rear end of the elevator crawler is connected to the crawler rod by a hinge, and the two sides of the front end are equipped with small wheels at the front end of the crawler, which are stuck in the crawler guide rail (see figure 1 ).

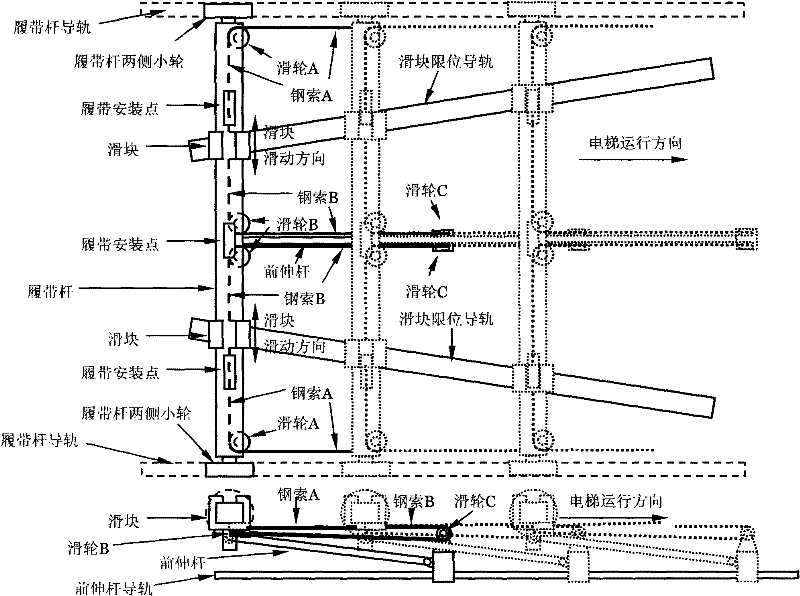

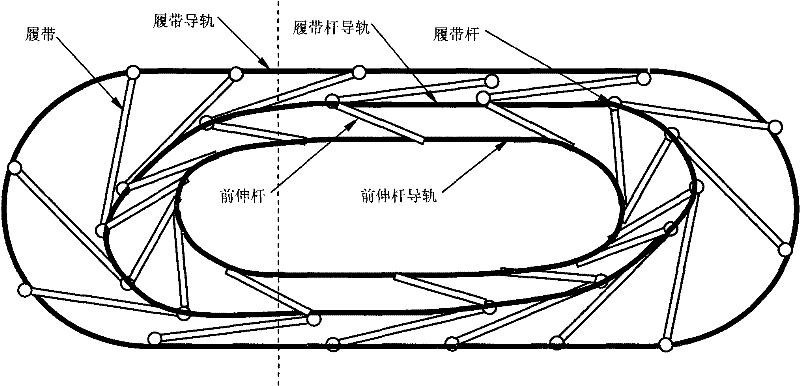

[0018] The crawler rod is in the horizontal plane and its direction is perpendicular to the running direction of the elevator. Both ends of the crawler rod are stuck in the guide rails of the crawler rod through the small wheels on both sides of the crawler rod and can slide forward (see figure 1 ). Tracks, sliders and cable mechanisms are installed on the track bar. When the elevator is running, the crawler rods drive the crawler belts to slide forward, and the distance between the crawler belts i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com