Optimization method for coal bed gas multi-branch horizontal well trajectory

A trajectory optimization, multi-branch technology, applied in earth-moving drilling, wellbore/well components, production fluid, etc., can solve the problems of not considering convenience and low gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0095] Among them, the trajectory of A coalbed methane multi-branch horizontal well (hereinafter referred to as well A) is not optimized by the above method; the trajectory of B coalbed methane multi-branch horizontal well (hereinafter referred to as well B) is optimized by the above method.

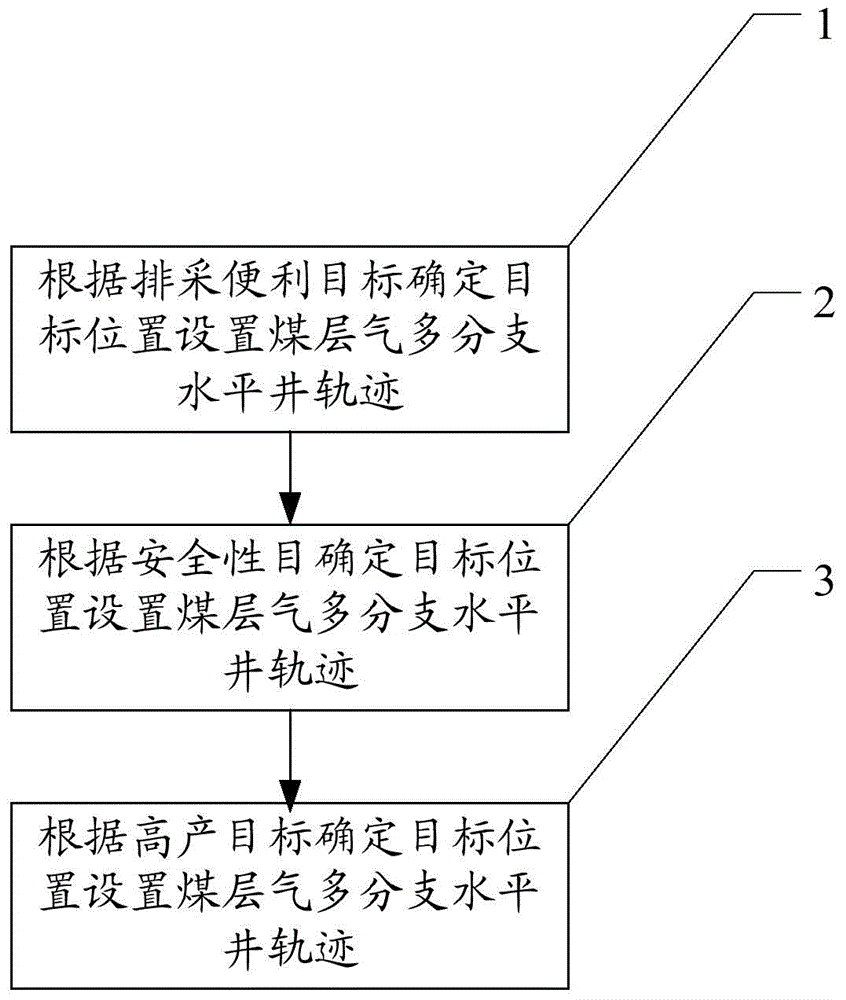

[0096] (1) Determine the target position according to the drainage convenience target and set the trajectory of the CBM multi-branch horizontal well.

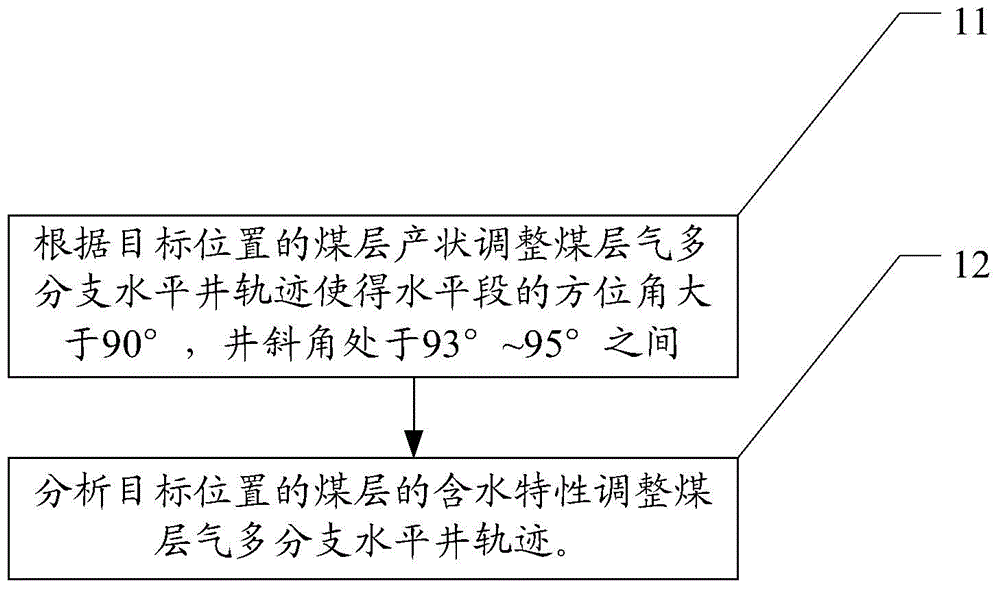

[0097] Optimization of coal seam occurrence and horizontal section trajectory azimuth: The coal seam in this well area has an inclination angle of 3° and a dip of 222°. According to the goal of facilitating drainage and production, the horizontal section trajectory azimuth of Well B is adjusted to be 42° north by east, and the inclination angle is 93° , see Figure 6 .

[0098] Optimize the trajectory of Well B according to the water content characteristics of the coal seam and roof and floor at the target location: use acoustic wave, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com