Planting Arm

A technology of planting arms and wide and narrow rows, which is applied in the field of planting arms of wide and narrow row splitting mechanism, which can solve the problems that seedlings are not perpendicular to the ground, different seedlings are not picked up at the same time; the seedling door and the direction of advancement, etc., to achieve good work quality and ensure verticality , Simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

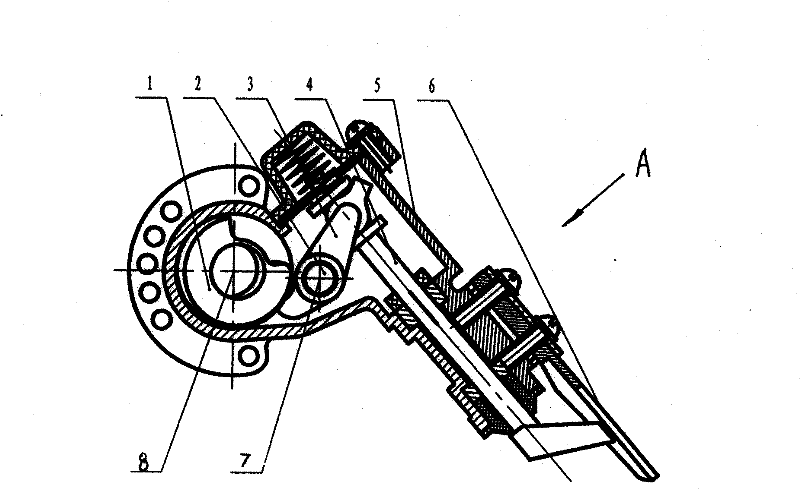

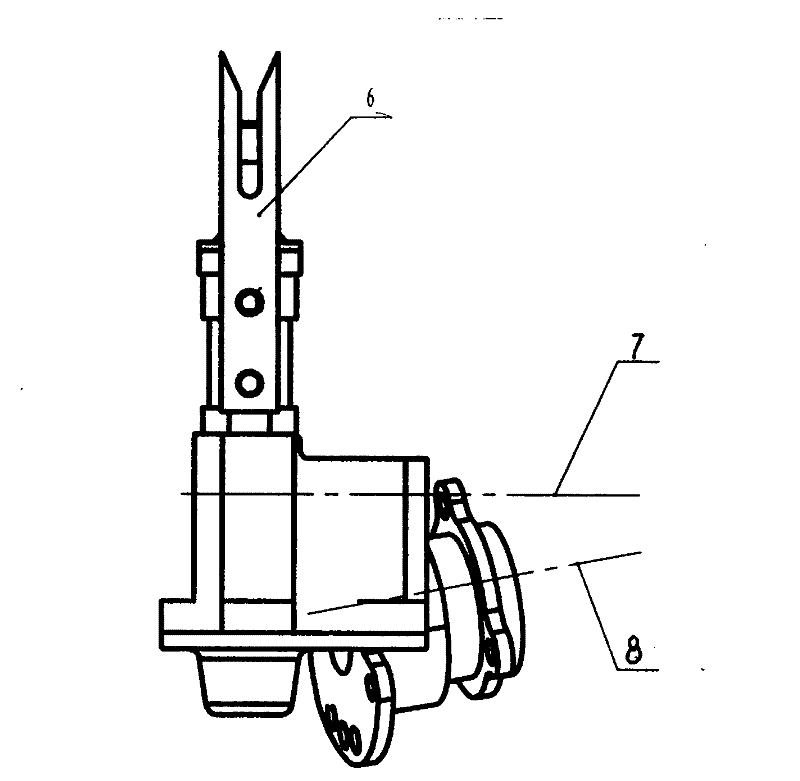

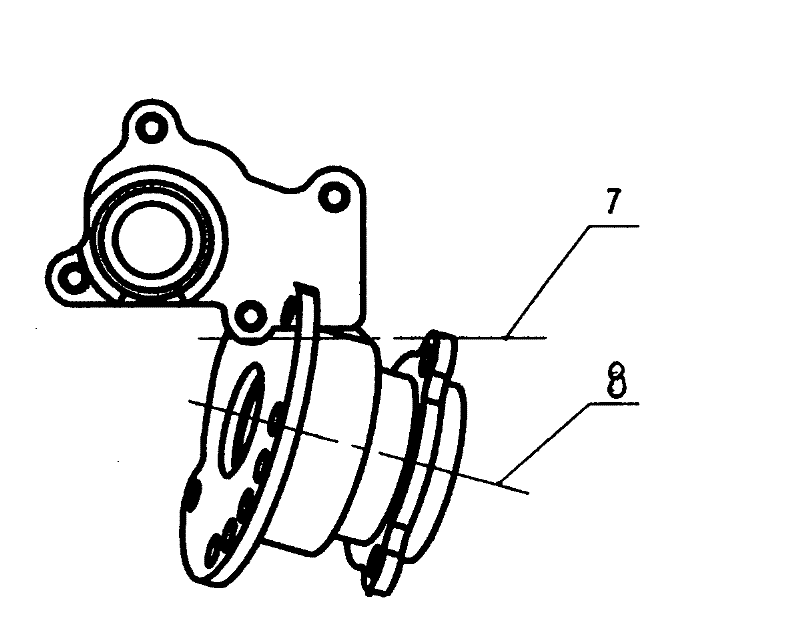

[0013] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The planting arm of the direct-fetching wide and narrow row planting mechanism includes a planting arm shell 5 and a cam 1, a fork shaft 2, a fork 3, and a seedling push rod 4 fitted in the planting arm shell 5. On the outer upper end surface of the planting arm housing 5, the cam axis 8 of the cam 1 and the fork axis 7 of the fork shaft 2 are arranged in a spatially staggered angle shape. The claws 6 are perpendicular to the seedling door of the rice transplanter, and the pushing rod 4 and the claws 6 are parallel to the forward direction of the rice transplanter.

[0014] In the present invention, the seedling claw 6 is rotated by two angles along the cam axis 8 and the fork axis 7 so that the seedling claw 6 is parallel to the horizontal plane, while ensuring that the center line of the seedling claw 6 is consistent with the forward direction, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com