Dismantling and transporting device of large pin shaft of crawler crane

A technology of crawler cranes and transportation devices, which is applied to cranes, hand-held tools, manufacturing tools, etc., can solve problems such as difficulty, high operating costs, and increased labor intensity of operators, so as to achieve convenient operation and reduce labor intensity and operating costs , High use value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] The large pin shaft disassembly and transportation device of the crawler crane of the present invention can realize the simple disassembly and assembly and separate transportation of the pin shaft, effectively reduce the weight of the main body of the crane, thereby reducing the labor intensity and labor time of the operator.

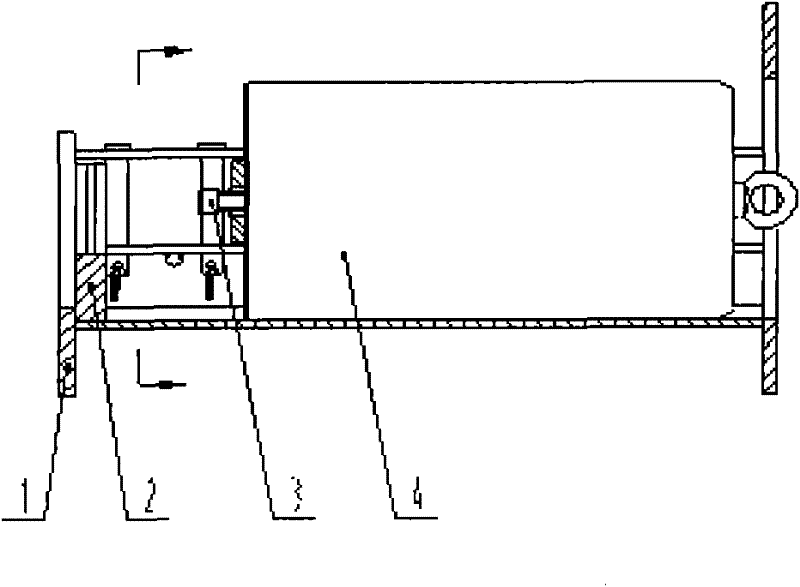

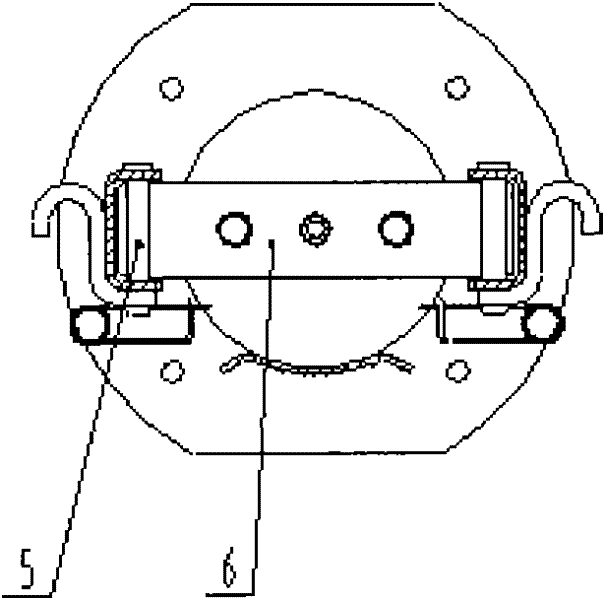

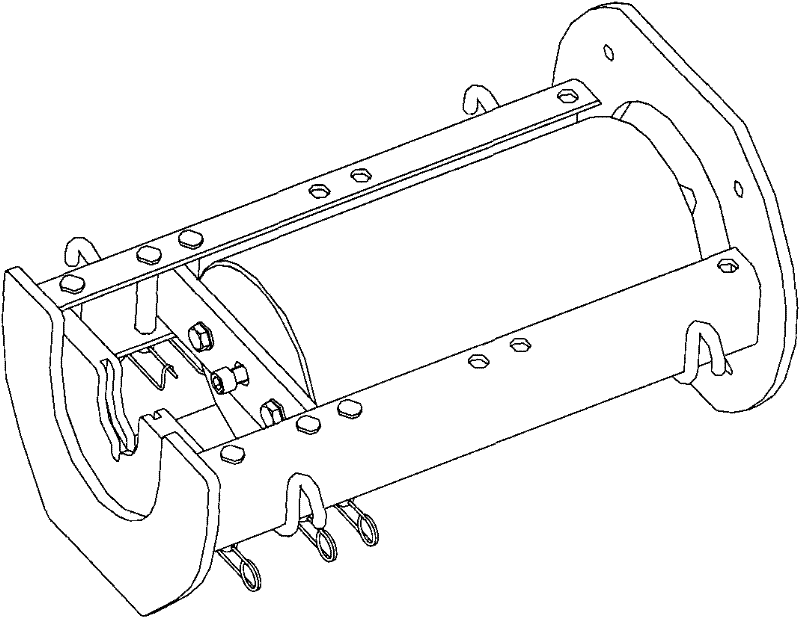

[0020] The structure of the large-scale pin shaft dismounting and transportation device of the crawler crane will be introduced in detail below. Figure 1-Figure 3 It is a transportation state diagram of the large pin shaft dismounting and transportation device of the crawler crane of the present invention. It can be seen from the figure that the device includes a bracket 1 whose main body is an arc-shaped pallet and two groove-shaped guide rails, so as to support the pin shaft and make it stable for transportation. One side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com