The forming method of three-color scissors

A scissors, cooling forming technology, used in household components, applications, household appliances, etc., can solve the problems of long product cycle, many processing workers, unqualified rate, etc., to improve the qualified rate, reduce manual processing, and shorten the product cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

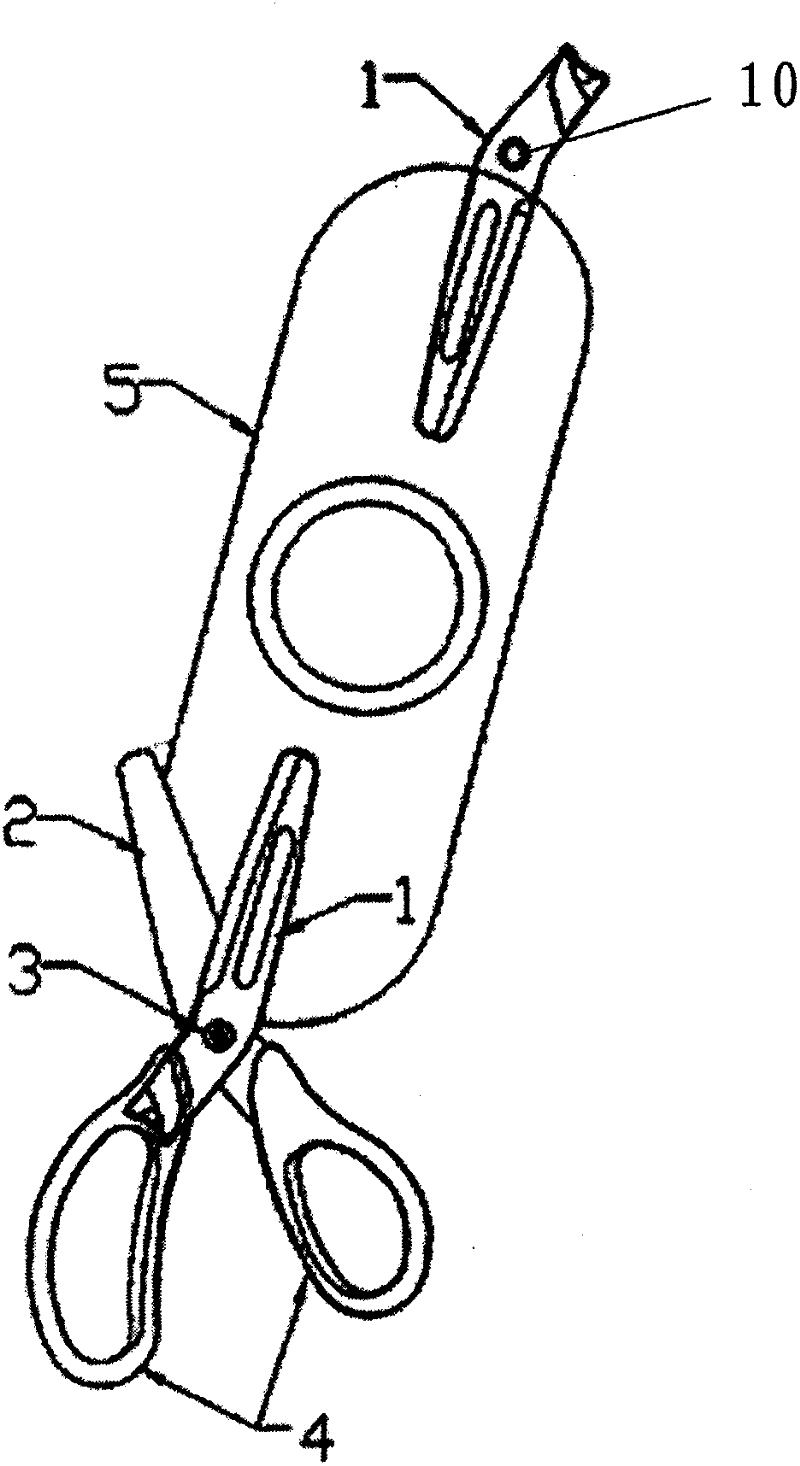

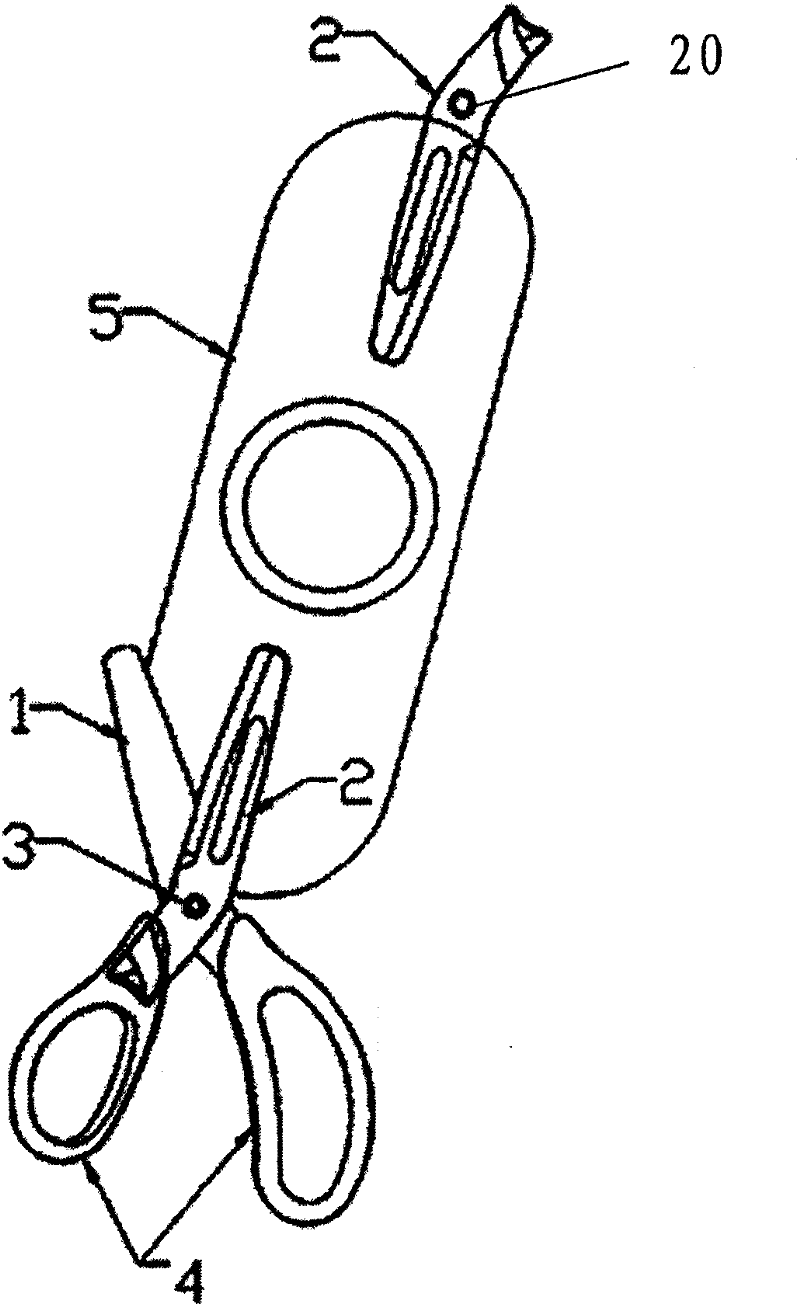

[0018] The specific embodiments of the present invention will be described in further detail below according to the accompanying drawings.

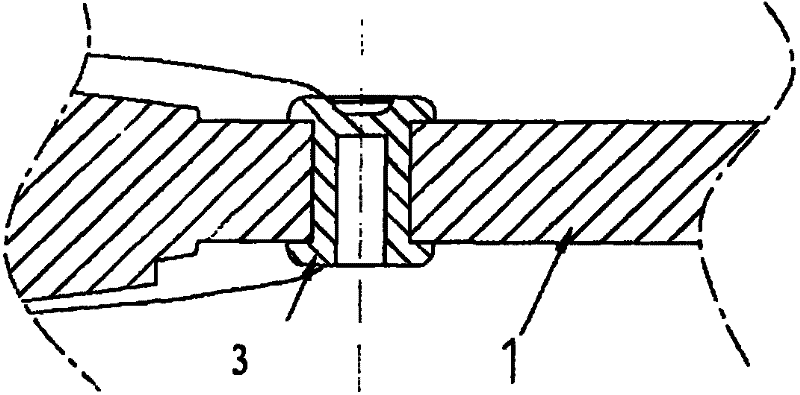

[0019] The working principle of the present invention is that various plastics have different melting temperatures, and all have different degrees of shrinkage (shrinkage) after injection molding. Therefore, the material with high melting temperature is injected first in one equipment, and then the material with low melting temperature is injected after cooling and setting, so that the materials will not be fused together, and then the different shrinkage rates of different rubber materials are used to produce active parts. gap to achieve a movable effect.

[0020] The concrete processing method of three-color scissors among the present invention comprises the steps:

[0021] 1) Use PC (Polycarbonate, polycarbonate) rubber material and 5 rotating mold cores to perform injection molding on the left and right blades respectively, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com