Method for reducing discharging quantity of standard part star discharge valve

A star-shaped unloading, standard parts technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of motor heating and burning, difficult to control the production process, etc., to prolong the service life, improve the performance of the device, and improve the production Or the effect of test efficiency and product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

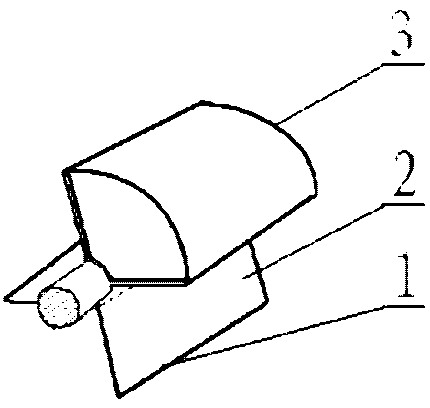

[0057] A method for reducing the discharge volume of a standard star discharge valve. The standard star discharge valve such as figure 1 As shown, the rotor structure is a fixed blade rotor. Known: the cavity volume V of the standard star discharge valve 1 =2 (liters); the number of blades 1 of the standard star discharge valve is N=4 (pieces), that is, the number of sub-cavities 2 of the standard star discharge valve is N=4 (pieces).

[0058] The first step, the actual production process requirements V 2 =1.5 (liter), the discharge volume of the standard star discharge valve should be reduced by V

[0059] V=V 1 -V 2 (1)

[0060] V=0.5 (liter).

[0061] The second step is to reduce the cavity volume V of the standard star discharge valve 1 Methods

[0062] 1) The volume of the sub-cavity 2 of the standard star discharge valve is v 1

[0063] v 1 =V 1 / N (2)

[0064] v 1 =2 / 4=0.5 (liter).

[0065] 2) According to the structure of the standard star d...

Embodiment 2

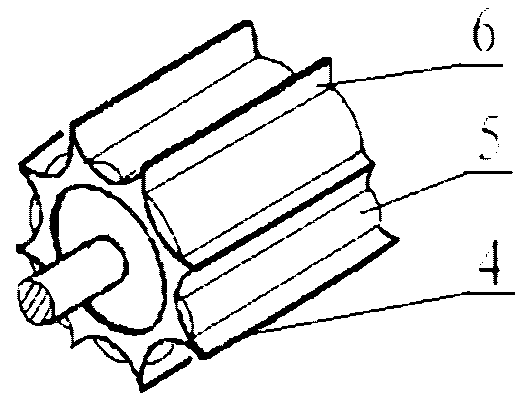

[0076] A method for reducing the discharge volume of a standard star discharge valve. The standard star discharge valve such as figure 2 As shown, the rotor structure is a scalloped rotor. Known: the cavity volume V of the standard star discharge valve 1 =2 (liter); the number N=8 (pieces) of blades 4 of the standard star discharge valve, that is, the number N=8 (pieces) of sub-cavities 6 of the standard star discharge valve.

[0077] The first step, the actual production process requirements V 2 =1.2 (liter), the discharge volume of the standard star discharge valve should be reduced by V

[0078] V=V 1 -V 2 ; (1)

[0079] V=2-1.2=0.8 (liter).

[0080] The second step is to reduce the cavity volume V of the standard star discharge valve 1 Methods

[0081] 1) The volume of the sub-cavity 6 of the standard star discharge valve is v 1

[0082] v 1 =V 1 / N (2)

[0083] v 1 =2 / 8=0.25 (liter).

[0084] 2) According to the structure of the standar...

Embodiment 3

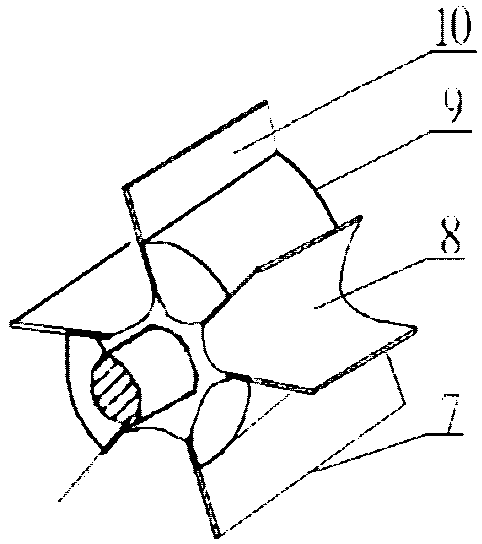

[0095] A method for reducing the discharge volume of a standard star discharge valve. The standard star discharge valve such as image 3 As shown, the rotor structure is a small round bottom rotor. Known: the cavity volume V of the standard star discharge valve 1 =2 (liter); the number of blades 7 of the standard star discharge valve N=6 (pieces), that is, the number of sub-cavities 8 of the standard star discharge valve N=6 (pieces);

[0096] The first step, the actual production process requirements V 2 =1.6 (liter); the discharge volume of the standard star discharge valve should be reduced by V

[0097] V=V 1 -V 2 (1)

[0098] V=2-1.6=0.4 (liter).

[0099] The second step is to reduce the cavity volume V of the standard star discharge valve 1 Methods

[0100] 1) The volume of the sub-cavity 8 of the standard star discharge valve is v 1

[0101] v 1 =V 1 / N (2)

[0102] v 1 =2 / 6=0.333 (liter).

[0103] 2) According to the structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com