Water release device for marine long shaft pump

A technology for pumps and water outlets, which is applied to parts of pumping devices for elastic fluids, pump elements, variable capacity pump parts, etc., can solve problems such as difficult water flow, and achieve low cost, simple structure, and easy manufacturing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

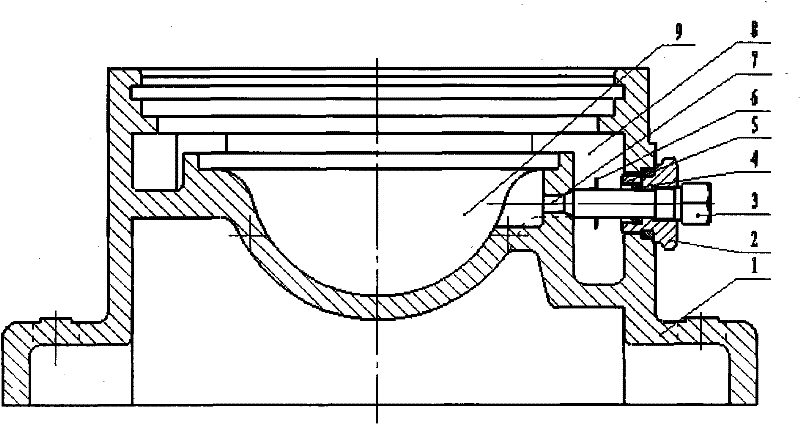

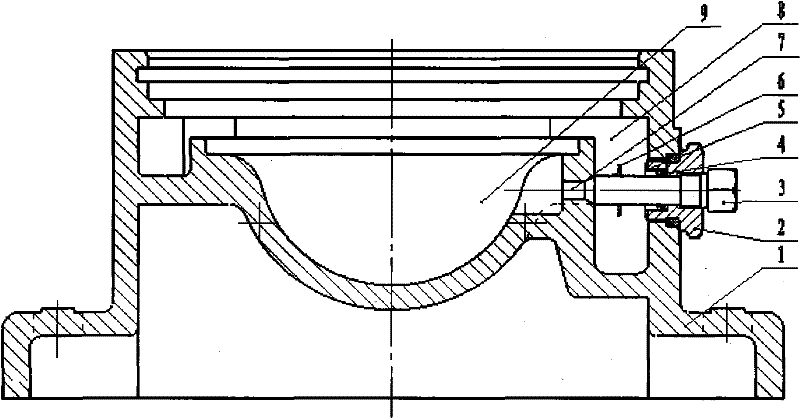

[0009] Depend on figure 1 As shown, a water outlet 7 is opened between the water suction chamber 9 and the water outlet chamber 8, and a hole coaxial with the axis of the water outlet 7 is opened on the pump body 1, and the hole is threaded with the water outlet screw body 2, And sealing ring 4 and sealing ring retaining ring 5 are housed, the passage of water suction chamber 9 and water outlet chamber 8 is controlled by drain bolt 3, and the degree of unscrewing of drain bolt 3 is controlled by stop ring 6. When the water discharge bolt 3 screwed in the water outlet 7 is tightened, the bolt head will block the water outlet 7, and the water suction chamber 9 and the water outlet chamber 8 will be closed; When the water outlet is 7, the water suction chamber 9 communicates with the water outlet chamber 8, and the water in the high-pressure water chamber flows into the low-pressure water chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com