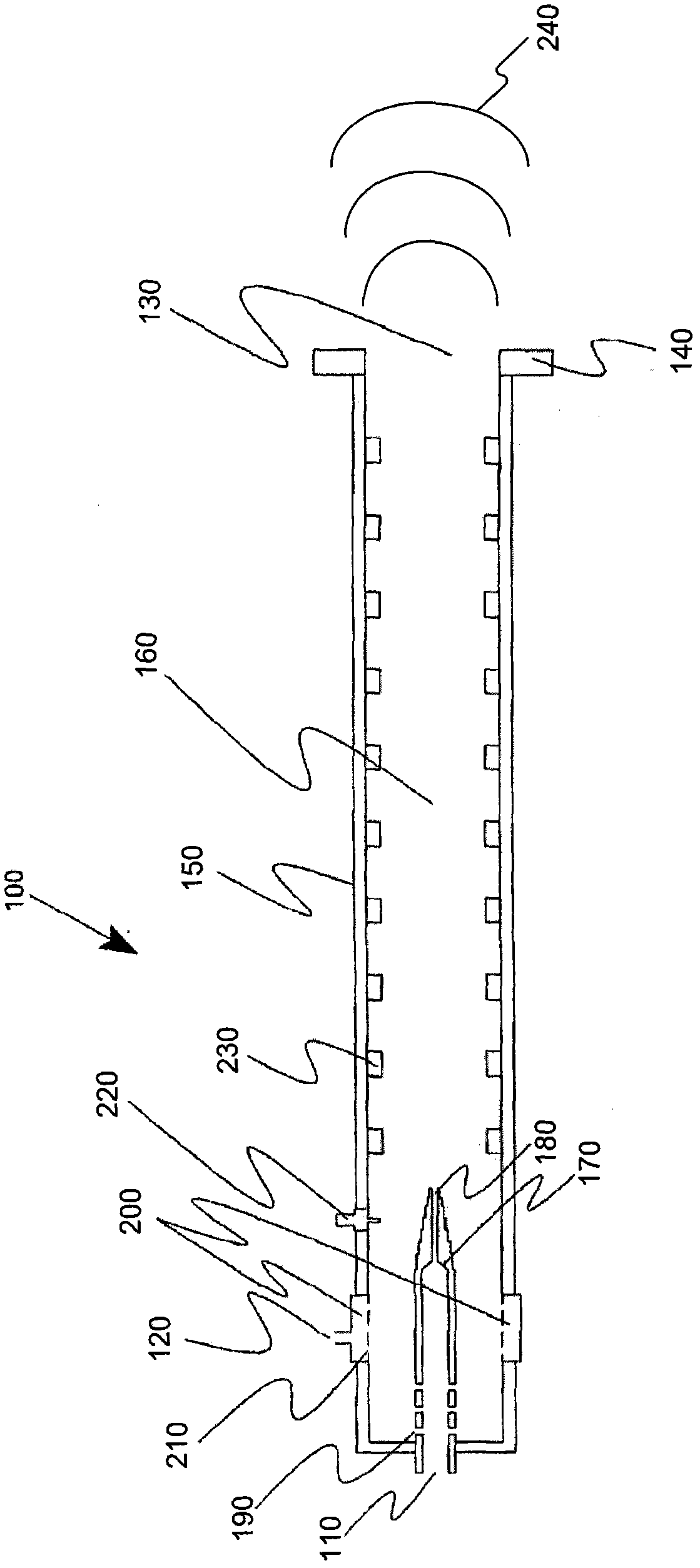

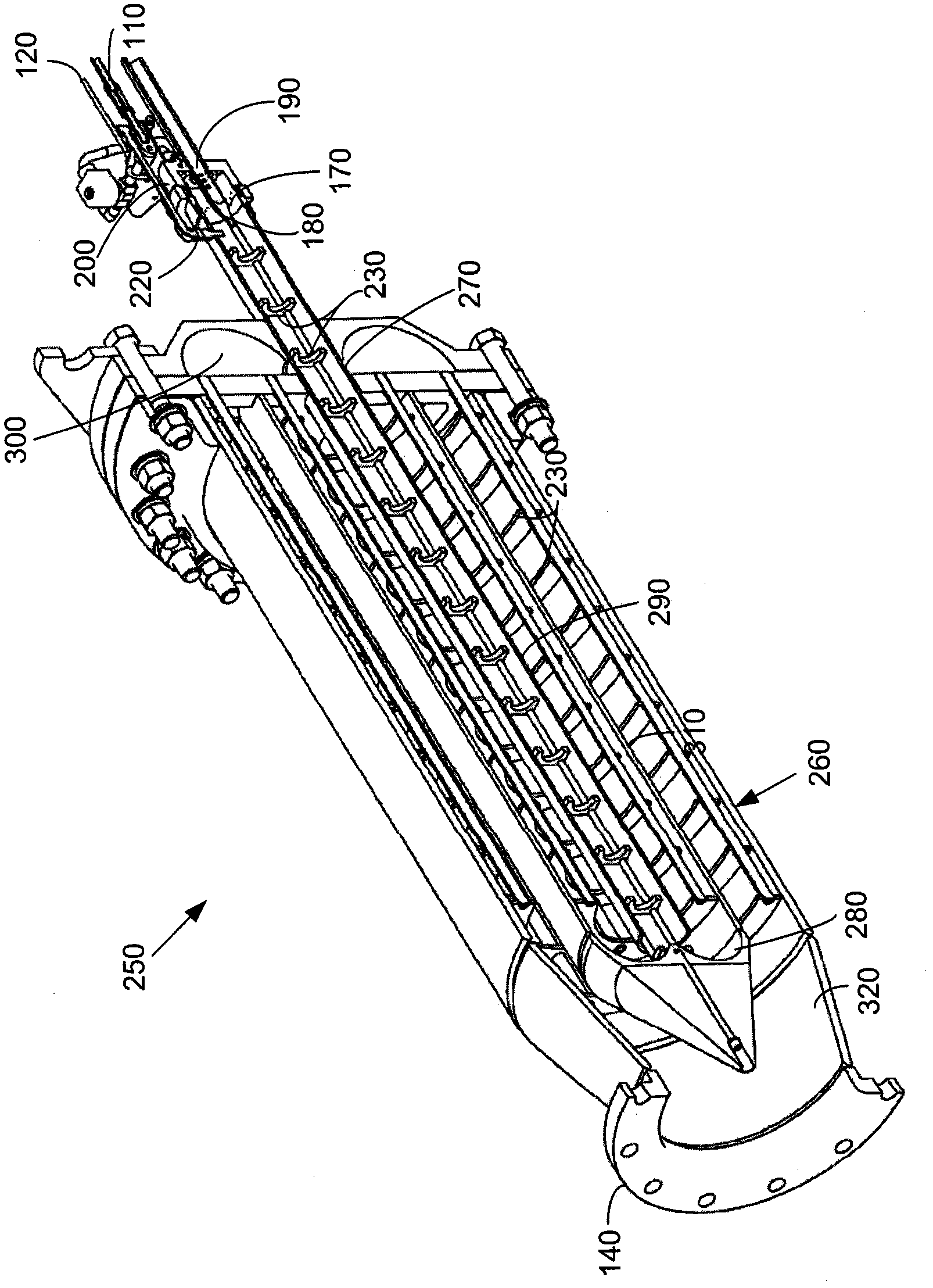

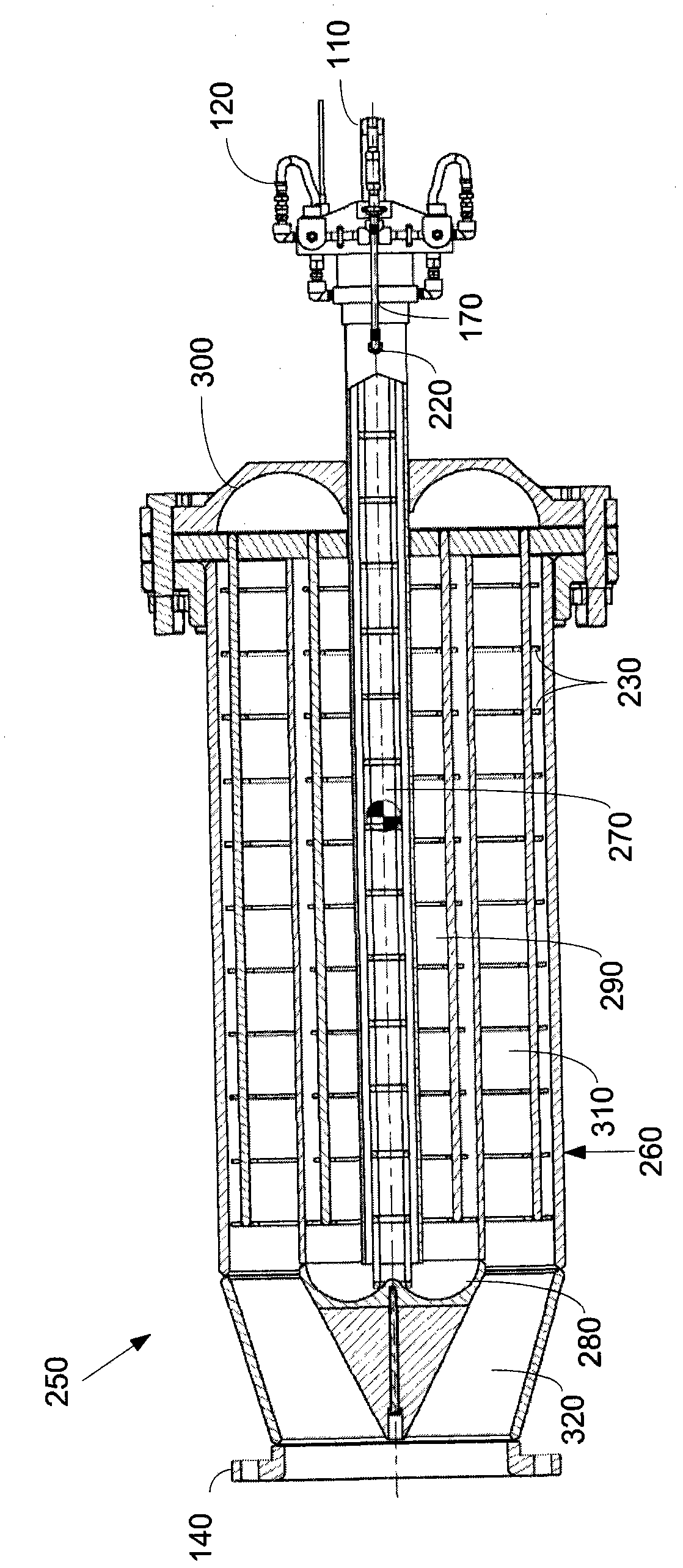

Pulse detonation cleaning unit with multiple folded flow paths

A cleaning device and pulse detonation technology, which is applied in the direction of cleaning heat transfer devices, descaling devices, combustion cleaning, etc., can solve the problems of not interfering with boilers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] As used herein, the term "pulse detonation combustor" ("PDC") refers to a device or system that uses detonation or quasi-detonation of fuel and oxidant to produce both a pressure rise and a velocity increase. The PDC can be operated in a repetitive mode to generate multiple detonations or quasi-detonations within the device. "Detonation" may be ultrasonic combustion, in which shock waves are coupled into the combustion zone. The shock can be maintained by the energy released from the combustion zone to cause the products of combustion to be at a higher pressure than the reactants of combustion. "Quasi-detonation" may be a supersonic turbulent combustion process that produces a higher pressure rise and velocity increase than that produced by an acoustic deflagration wave. For simplicity, as used herein, the term "detonation" or "detonation wave" shall include both detonation and quasi-detonation.

[0037] Exemplary PDCs, some of which are discussed in more detail below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com