Sintering-atmosphere loss-free obstacle-removing device for ferrite-sintering furnace

A sintering kiln and sintering atmosphere technology, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problems of wasting energy, unseen, and the impact of continuous production of sintering furnaces, so as to ensure normal work and balance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable the examiners of the patent office, especially the public, to understand the technical essence and beneficial effects of the present invention more clearly, the applicant will describe in detail the following in the form of examples, but none of the descriptions to the examples is an explanation of the solutions of the present invention. Any equivalent transformation made according to the concept of the present invention which is merely formal but not substantive shall be regarded as the scope of the technical solution of the present invention.

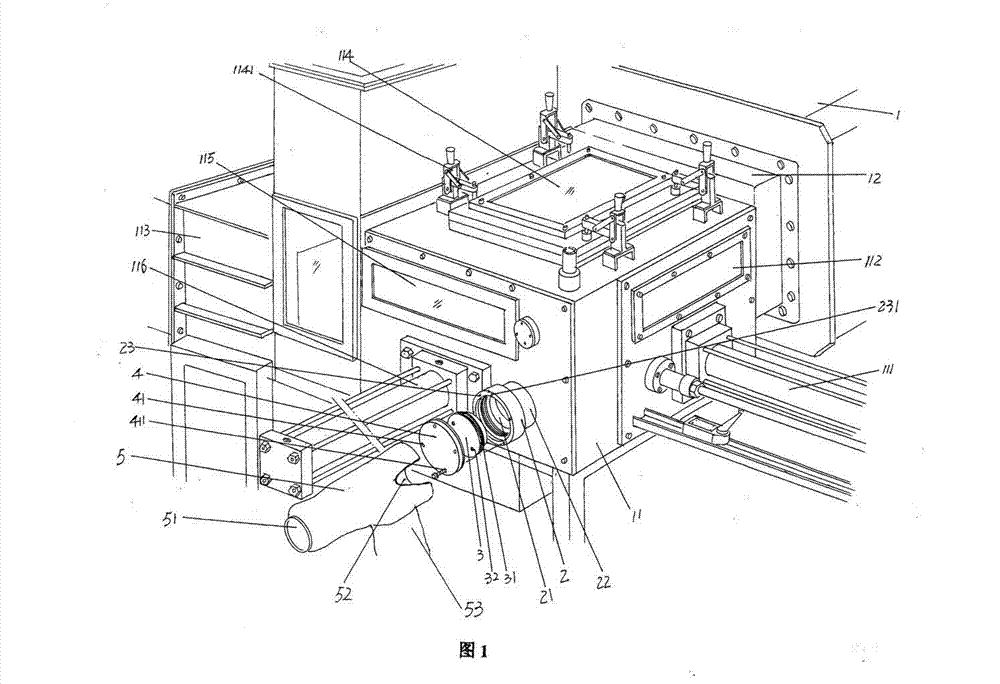

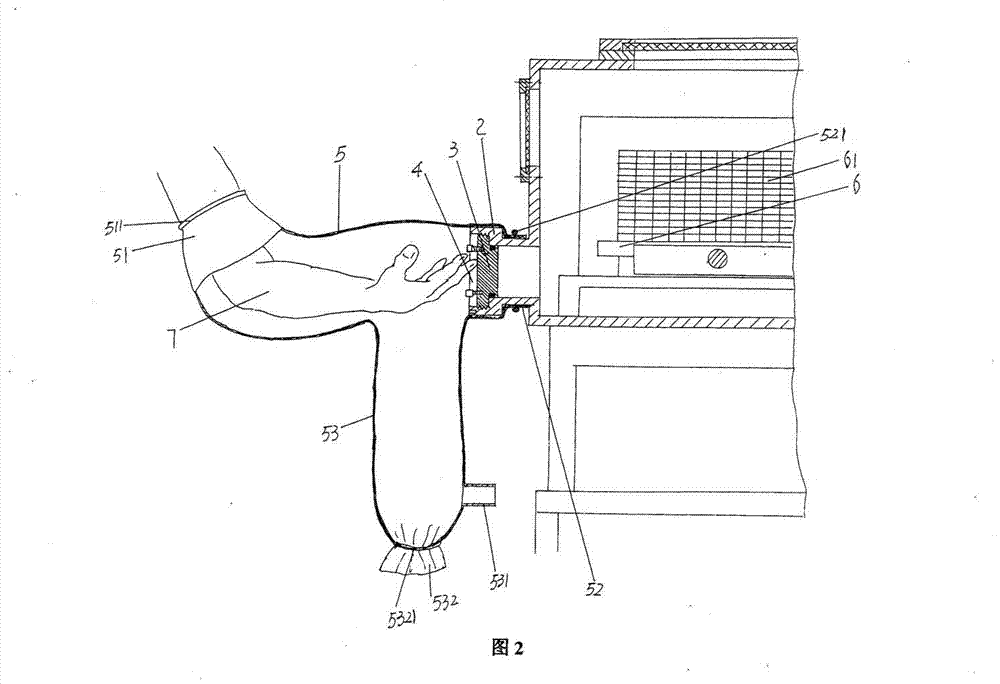

[0016] See figure 1 , provides the same discharge transition box 11 as the known technology, and the discharge transition box 11 is matched with the furnace outlet 12 of the ferrite sintering kiln 1. On one side of the discharge transition box 11 that is figure 1 The right side of the shown position state is equipped with a pusher cylinder 111, and a first window 112 is arranged on the side (the afore...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap