Method for maintaining state of power transmission equipment based on system risk

A technology for power transmission equipment and state-of-the-art maintenance, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as excessive equipment maintenance, affecting the accuracy of test results, and waste of maintenance resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

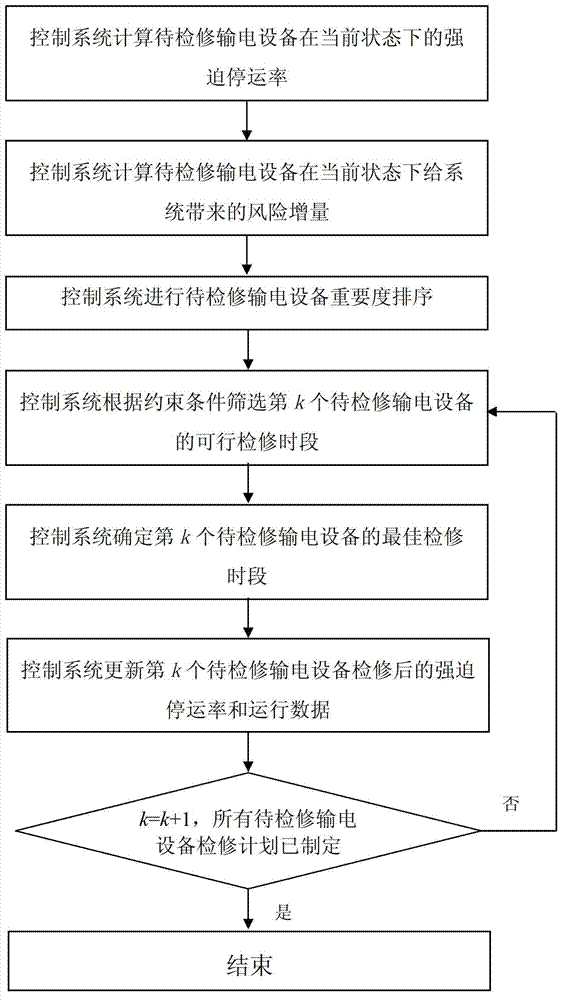

[0073] Such as figure 1 As shown, a condition-based maintenance method for power transmission equipment based on system risk, the steps are as follows:

[0074] Step 1: First, obtain the comprehensive status score data of the power transmission equipment to be repaired in real time through the sensors corresponding to the power transmission equipment to be repaired. There is an exponential relationship between the equipment status score and the failure rate:

[0075] λ=A×e B×ISE +C (1)

[0076] In the formula:

[0077] λ——failure rate of power transmission equipment to be repaired (times / year);

[0078] ISE—the comprehensive status scoring data of power transmission equipment to be repaired, based on the "Guidelines for Status Evaluation of State Grid Corporation of Power Transmission and Transformation Equipment Q / GDB169-173-2008" a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com