Transmission mechanism for valve of switch cabinet

A transmission mechanism and cabinet work technology, applied in the direction of switchgear components, etc., can solve the problem of reducing the effective transmission displacement of the transmission mechanism, the small travel of the handcart of the central circuit breaker, and the small distance between the contact arm of the handcart and the contact box, etc. problem, to achieve the effect of high fixing strength, small transmission error, and prevention of left and right sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

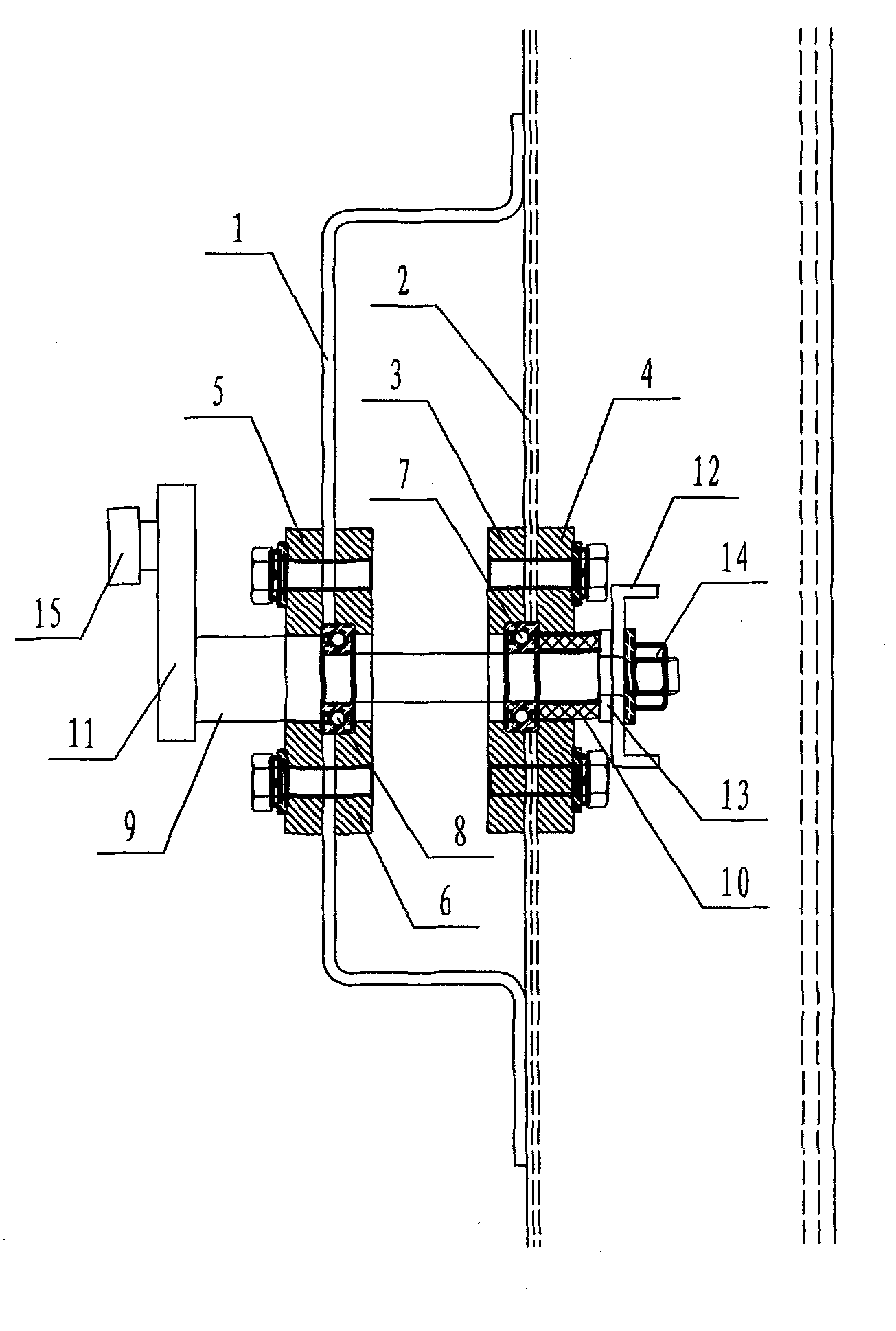

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] As shown in the figure, the handcart guide rail 1 is fixed on the left side of the side wall 2 of the cabinet body, and there is a certain distance between them. The bearing fixing plate I3 and the bearing baffle plate I4 are respectively fixed on the left and right sides of the side wall 2 of the cabinet body. The bearing baffle plate II5 and the bearing fixing plate II6 are respectively fixed on the left and right sides of the handcart guide rail 1. The bearing baffle II5, the handcart guide rail 1, the bearing fixing plate II6, the bearing fixing plate I3, the cabinet side wall 2 and the bearing baffle I4 are respectively provided with round holes through which the transmission shaft 9 passes sequentially, wherein the bearing baffle II5, the bearing The diameters of the round holes of the fixing plate II6, the bearing fixing plate I3 and the bearing baffle I4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com