expandable shaft

A shaft-aligned, gripping device technology, applied in the field of expanding the expandable shaft, can solve the problems of replacement core impact, easy to be affected by impact, damage to the profile, etc., to achieve weight reduction, easy disassembly, and cost increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

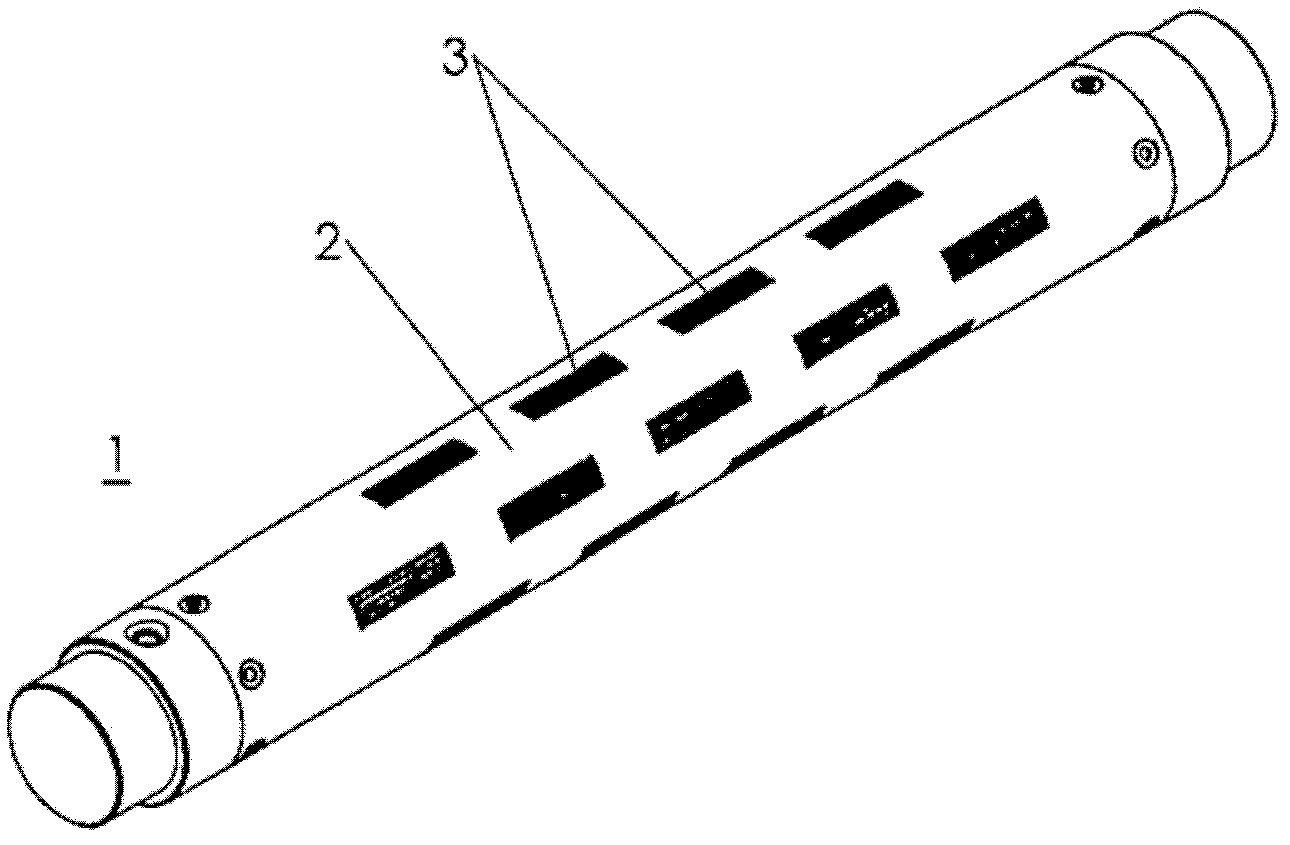

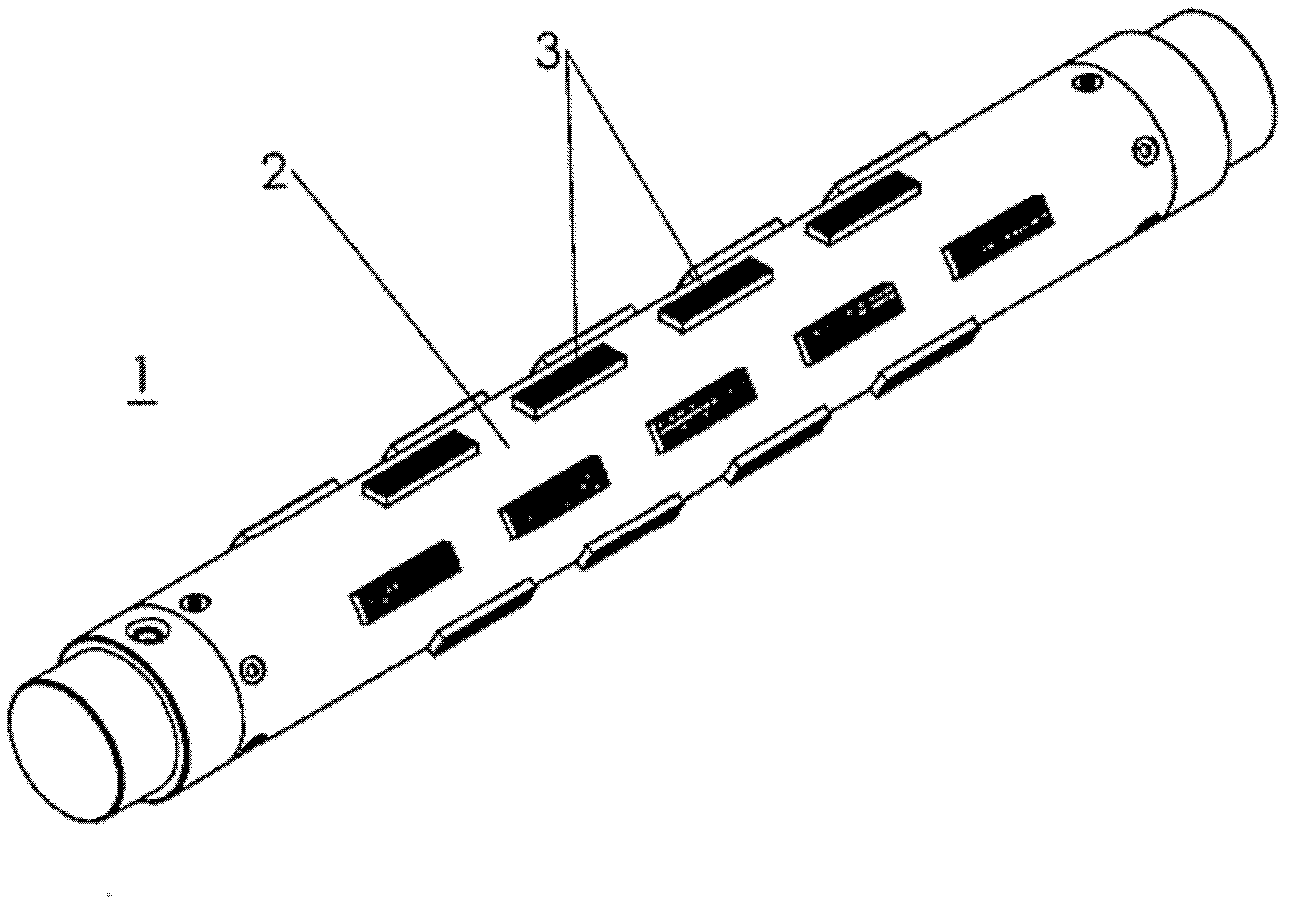

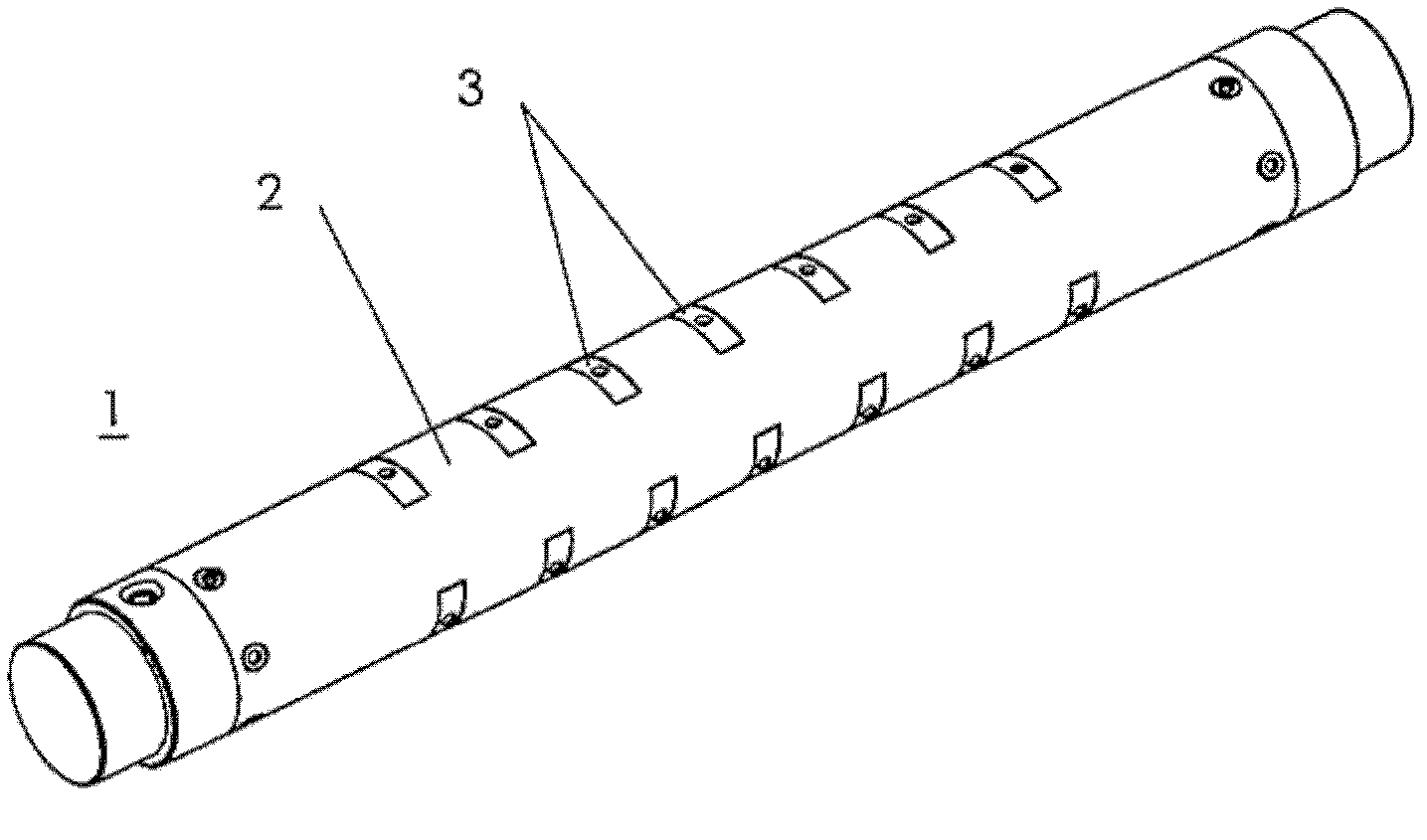

[0048] The present invention will be explained in more detail with reference to preferred embodiments shown in the drawings. In those figures, the reference number 1 refers to the expandable shaft according to the present invention. The expandable shaft 1 has an outer cylindrical tube 2 including a plurality of openings in which the holding device 3 is aligned. The holding device 3 can protrude along the radial direction of the shaft and beyond the tube. The holding device 3 is adapted to move radially between a first position and a second position according to an undisclosed inflatable cavity. in figure 1 , The holding device 3 is elongated along the longitudinal direction of the shaft 1, and the holding device 3 is in the first position. During the expansion of the undisclosed inflatable cavity, the holding device 3 will move from the first position to the second position, beyond figure 2 The external cylindrical tube 2 is disclosed. In the second position, the holding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com