Drawing die

A technology of drawing dies and punches, applied in the field of drawing dies, can solve problems such as wrinkling and cracking of parts, uneven material flow, large cross-section differences, etc., to shorten the development cycle, smooth material flow, reduce The effect of development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the characteristics and technical content of the present invention, please refer to the following detailed description and drawings related to the present invention, but this description and the accompanying drawings are only used to illustrate the present invention, not to limit the present invention.

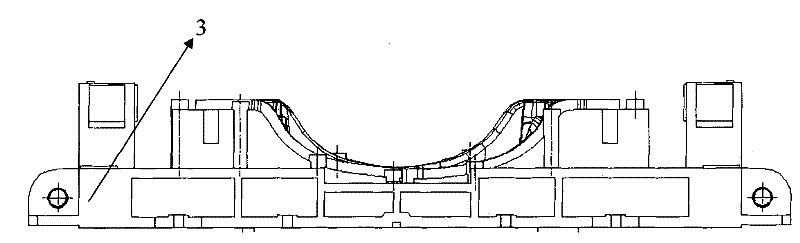

[0023] Such as figure 1 As shown, it is a schematic diagram of the assembly structure of the drawing die of the present invention. The drawing die includes two independent punches 4, a die 3 and a "day"-shaped blank holder 5. When in use, two punches 4 are placed on the The "day"-shaped blankholder 5, place a plate on the blankholder 5, place the die 3 on the plate, and then fix the drawing die through the upper mold base 1 and the lower mold base 2 to realize the drawing of the plate. delay.

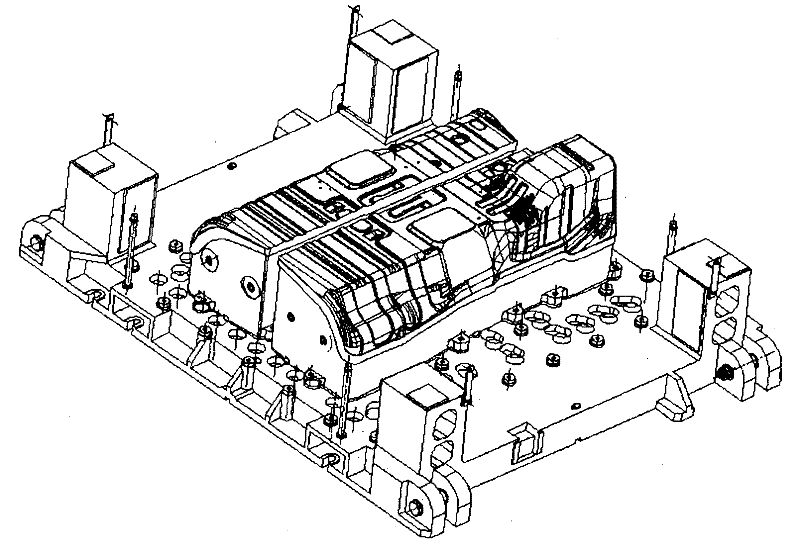

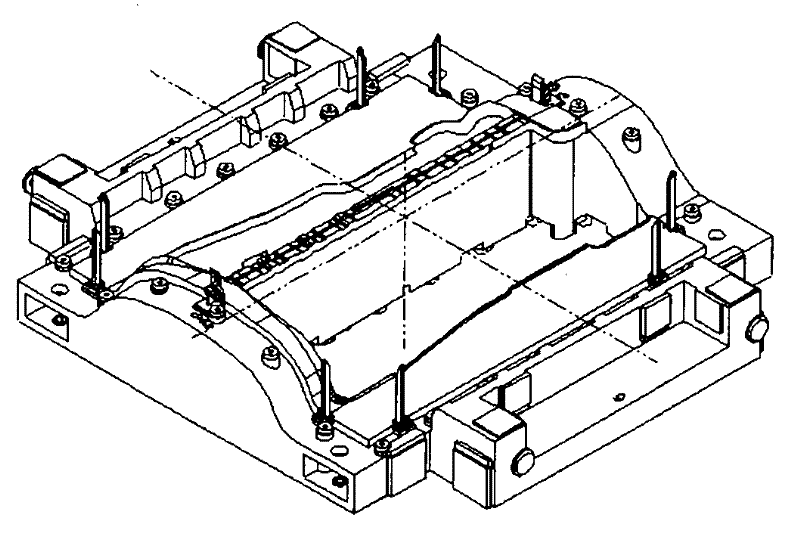

[0024] Such as figure 2 Shown is the three-dimensional schematic view of the die of the present invention, image 3 It is a sectional view of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com