Large-cylinder diameter upright post cylinder-removing machine

A large cylinder diameter, cylinder dismantling machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of difficult disassembly of guide sleeves, achieve the effect of convenient disassembly and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The large-bore column dismantling machine of the present invention, its preferred embodiment is:

[0016] It includes a bed, a power bed head, and a tailstock. The power bed head is connected with a driving device through a ratchet assembly, and the ratchet assembly is provided with an afterburner jack.

[0017] The tailstock is provided with a clamping oil cylinder and a manual clamping device.

[0018] A plurality of fixed seats are arranged on the bed, and a tailstock jack is arranged between the tailstock and the fixed seats.

[0019] One or more brackets are arranged on the bed.

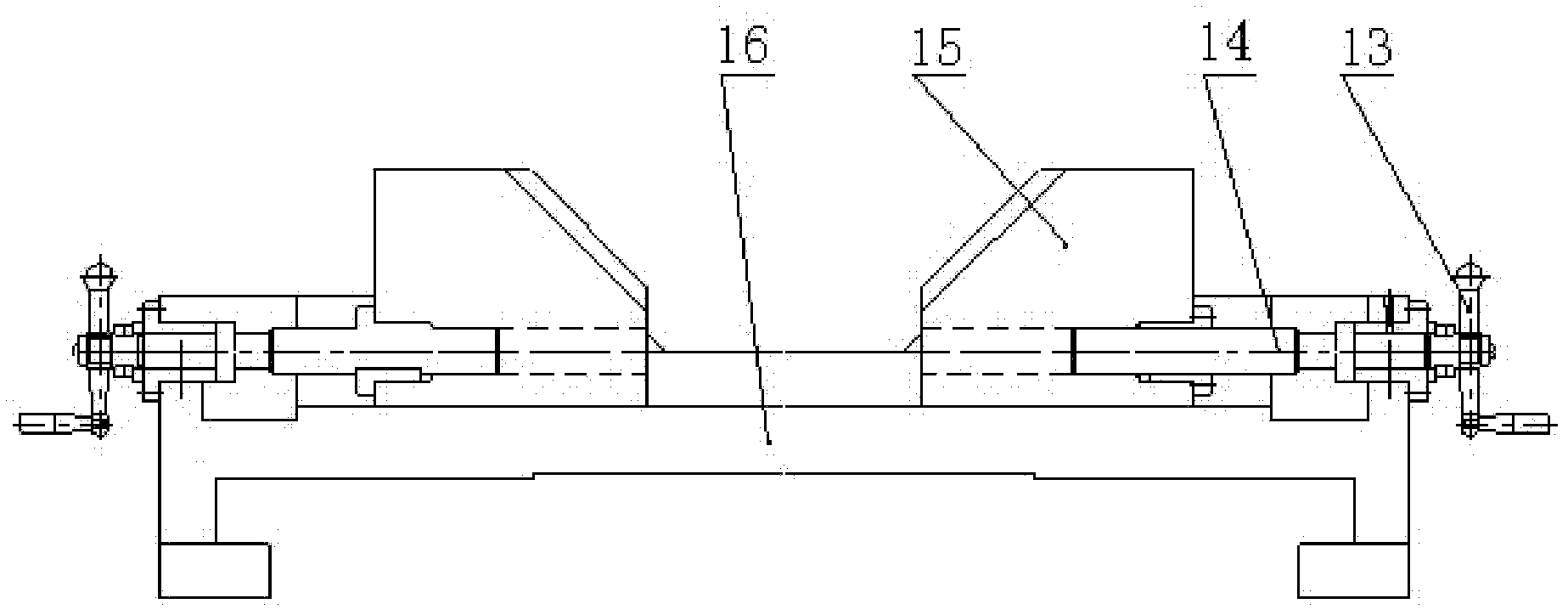

[0020] The bracket includes a frame body, a V-shaped iron is arranged on the frame body, a lead screw is arranged between the frame body and the V-shaped iron, and a handle is arranged at the rear end of the lead screw.

[0021] The drive means includes a hydraulic motor or an electric motor.

[0022] The bore of the large bore column is greater than or equal to 400mm.

[0023] The bo...

specific Embodiment

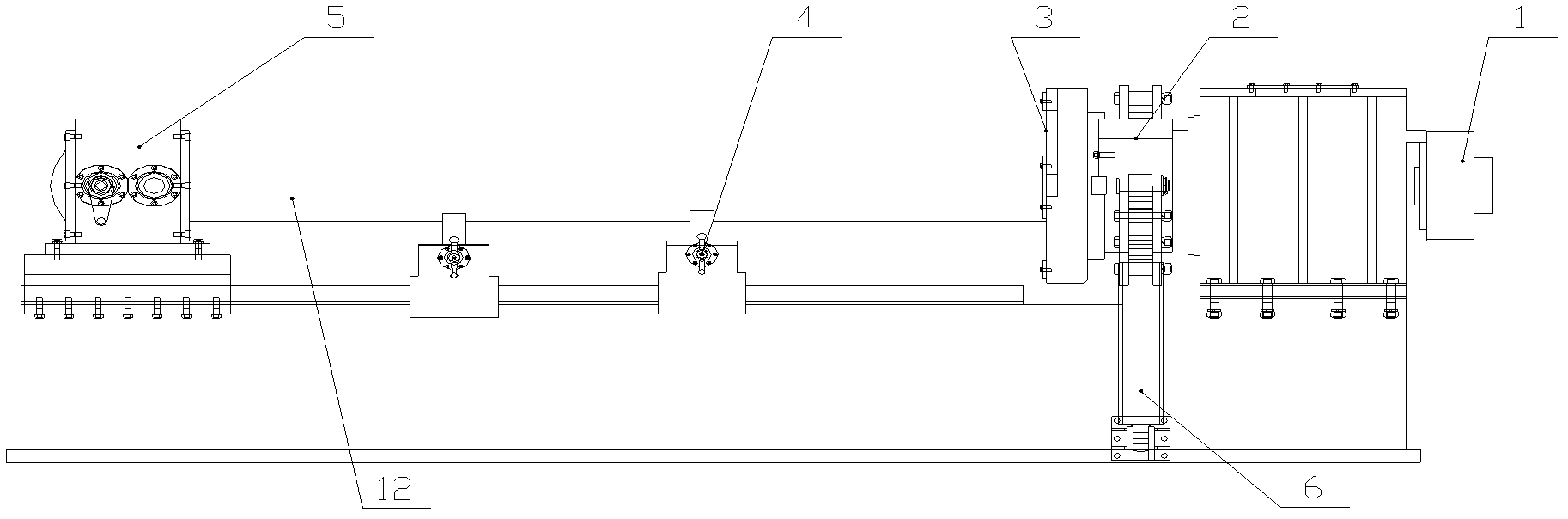

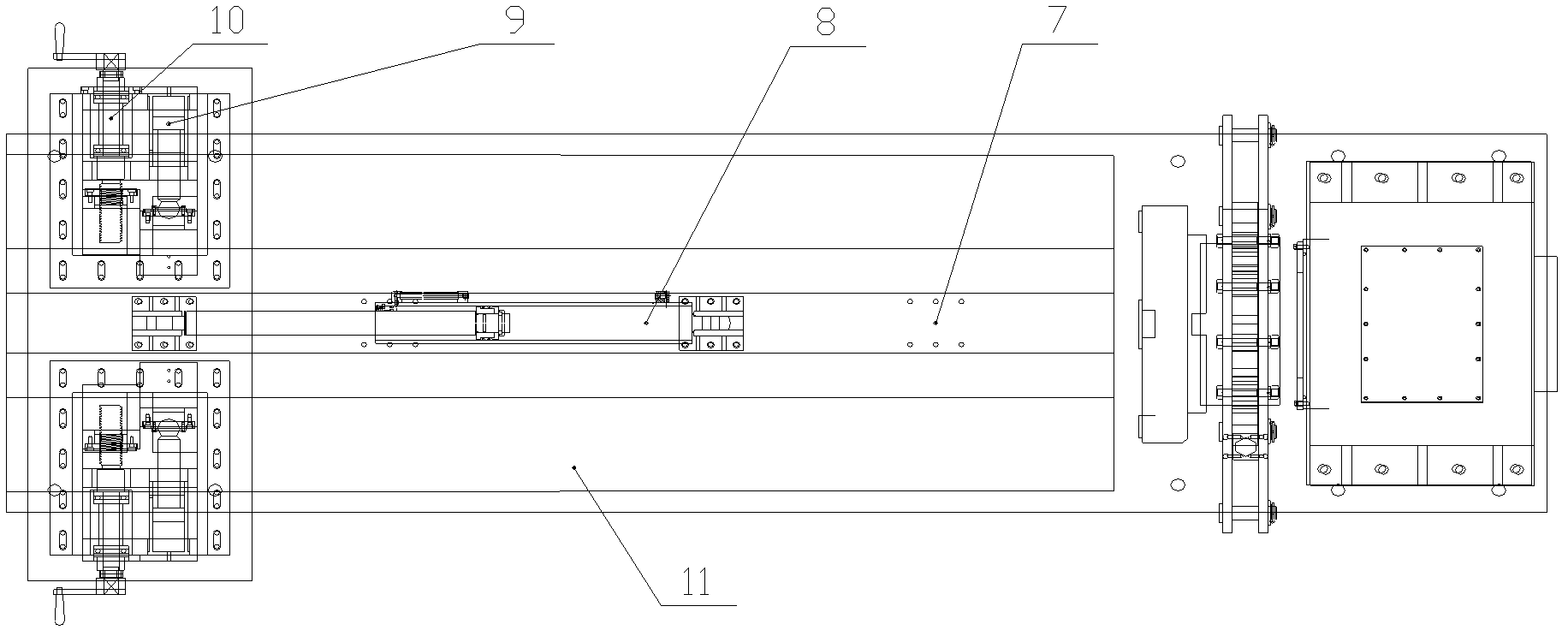

[0026] Such as figure 1 , figure 2 As shown, the column 12 to be dismantled is fixed by the power bed head 3 and the tailstock 5, and the column 12 to be dismantled is supported by the bracket 4. Wherein, tailstock 5 is fixed with the cylinder body of column 12 to be dismantled, and the head of a bed 3 is fixed with the dismantling wrench supporting with column 12 to be dismantled, and dismounting wrench is fixed with the guide sleeve of column 12 to be dismantled.

[0027] During disassembly, first the ratchet assembly 2 is driven by the afterburner jack 6 to drive the power bed head 3 to rotate, and the power head head 3 rotates by driving the disassembly wrench to unscrew the guide sleeve; then the hydraulic motor 1 provides power to complete the follow-up disassembly work.

[0028] The function of clamping the column of the tailstock 5 is jointly completed by the clamping cylinder 9 and the manual clamping device 10, wherein the manual clamping device 10 is mainly used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com