Telescopic truss structure and manufacturing method thereof

A truss structure and truss technology, which is applied to the fuselage frame and other directions, can solve the problems of large space occupation and inconvenient operation, and achieve the effects of less manpower demand, high efficiency, and simple and convenient telescopic operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

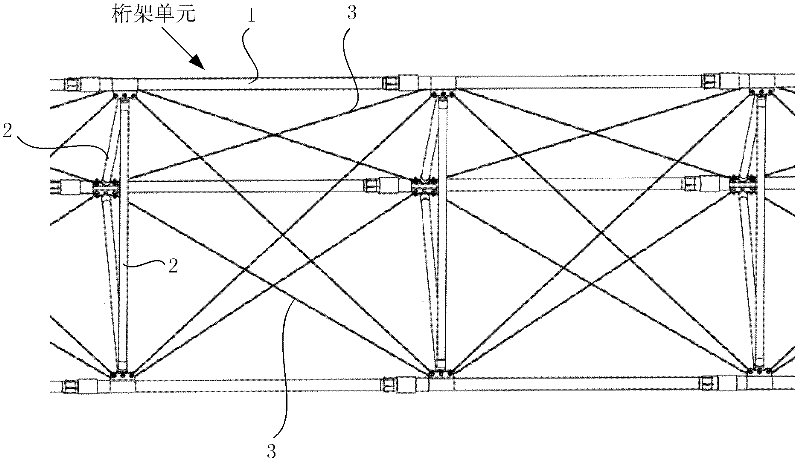

[0069] In the embodiment, the maximum elongation length of the truss structure is 10130 mm, the minimum shortening length is 3110 mm, the cross section is an equilateral triangle, and the length of the transverse rib 2 is 1000 mm.

[0070] A stretchable truss structure such as Figure 11 As shown, it is composed of ten truss units, and the transverse rib 2 is processed and formed by lightweight high-strength carbon fiber composite material, which mainly plays the role of support and connection. The inner diameter of the pipe is 23.8mm, the outer diameter is 25mm, and the length is 857mm.

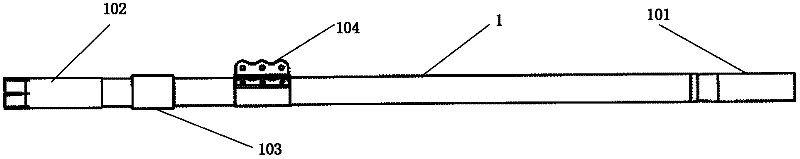

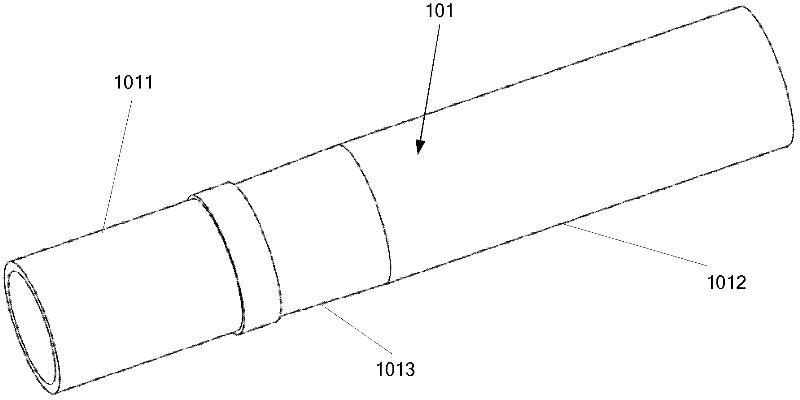

[0071] The longitudinal main girder 1 is processed and formed by light-weight high-strength carbon fiber composite material, which mainly plays the role of support and connection. The specific specifications of each pipe fitting are shown in Table 1.

[0072] Table 1 Main Rod Specifications

[0073]

[0074] The first telescopic sleeve 101 , the second telescopic sleeve 102 , the third t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com