Device for forming photoselective absorbing coating on the surface of wide-format metal substrate

A metal baseband and absorption coating technology, which is applied in the field of devices for forming a light selective absorption coating on the surface of a wide-format metal baseband, can solve the adverse effects of the performance indicators such as the density and uniformity of the coating, the effect is not obvious, and the light Selectively absorb the problems of unqualified coatings, etc., to achieve the effect of improving the uniformity of the concentration of the plating solution and the superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

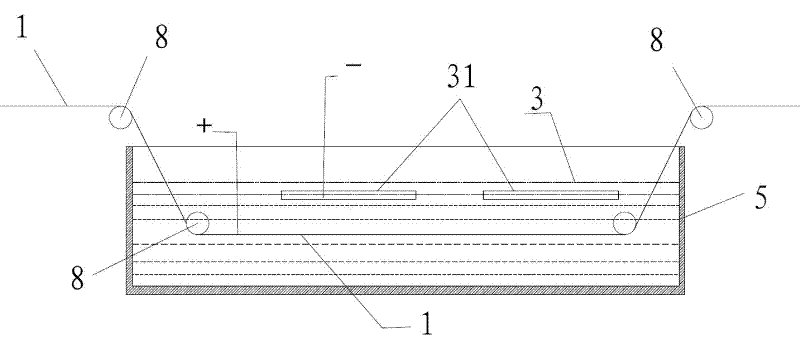

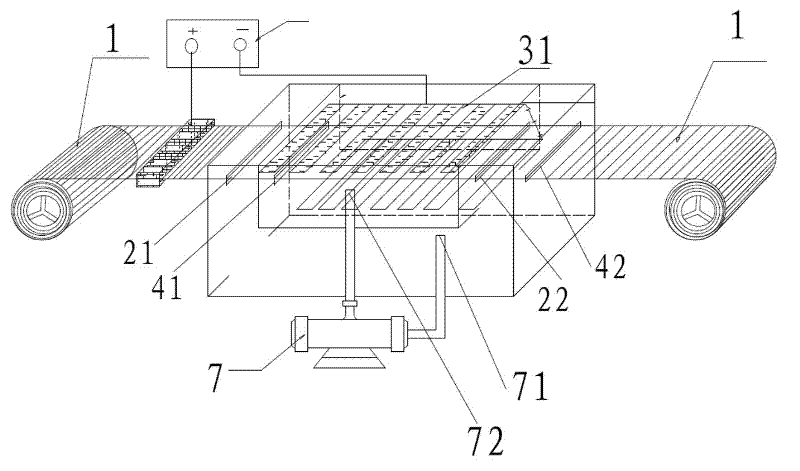

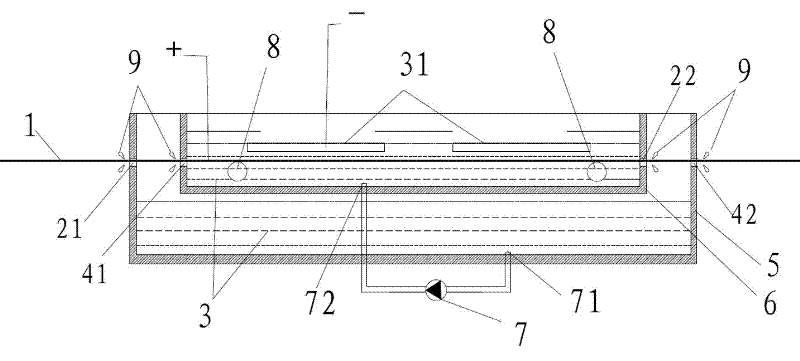

[0015] The device for forming a photoselective absorbing coating on the surface of a wide-format metal substrate according to the present invention, its specific structure can be found in figure 2 and image 3 , specifically including an oxidation coating tank with a first aluminum strip inlet 21 and a first aluminum strip exit 22 on opposite sides, and a wide aluminum plate (ie: metal aluminum plate) 1 from figure 2 The shown uncoiling part is unrolled and input, enters the mother tank 5 of the oxidation coating tank through the first aluminum strip inlet 21, and then enters the sub-tank 6 through the second aluminum strip inlet 41, and the plating solution 3 for anodizing is contained in the sub-tank and the sub-tank. In the tank 6, the liquid level can be slightly higher than the metal aluminum plate 1, so that the metal aluminum plate 1 is immersed in the plating solution 3, the metal aluminum plate itself is connected to the anode of the power supply, and the electropla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com