A device for cleaning fluff on the surface of fabric

A technology of cleaning device and fluff, applied in mechanical cleaning, high pressure cleaning, textile and papermaking, etc., can solve the problems that affect the quality of finished fabrics and the brush can not be completely brushed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

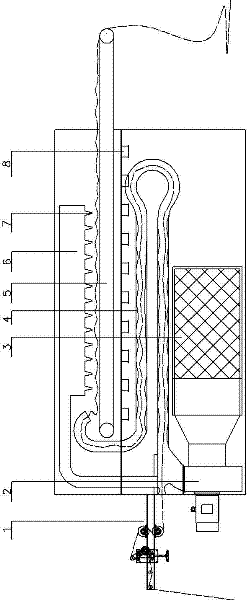

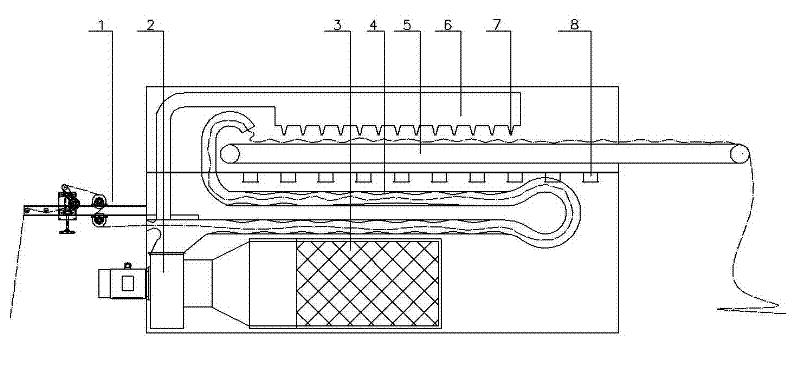

[0011] See figure 1 , the present invention comprises cloth tensioner guide roller 1 and conveying mesh belt 5, also comprises blower fan 2, air duct; Fan 2 air inlet places are provided with filter screen 3, and the air outlet of fan 2 communicates with air duct; The lower two roads, the lower air duct 4 is a soft material air duct, which can vibrate in a wave shape under the action of the wind, the lower air duct 4 is set in a roundabout way, and the air outlet end is bent into a semicircle and then vertically faces the conveying network On the upper surface of the belt 5, the air outlet 7 is evenly arranged at the air outlet end of the upper air duct 6, which is vertically facing the upper surface of the conveying mesh belt 5; The 5 lower part is provided with a plurality of velvet leakage holes 8 on the side of the frame, and the lower edge of the velvet leakage holes 8 is connected to the storage bag. In addition, the air inlet of the fan is provided with a filter screen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com