taxi brake inhibit system

A technology of brakes and braking force, applied in the direction of brakes etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

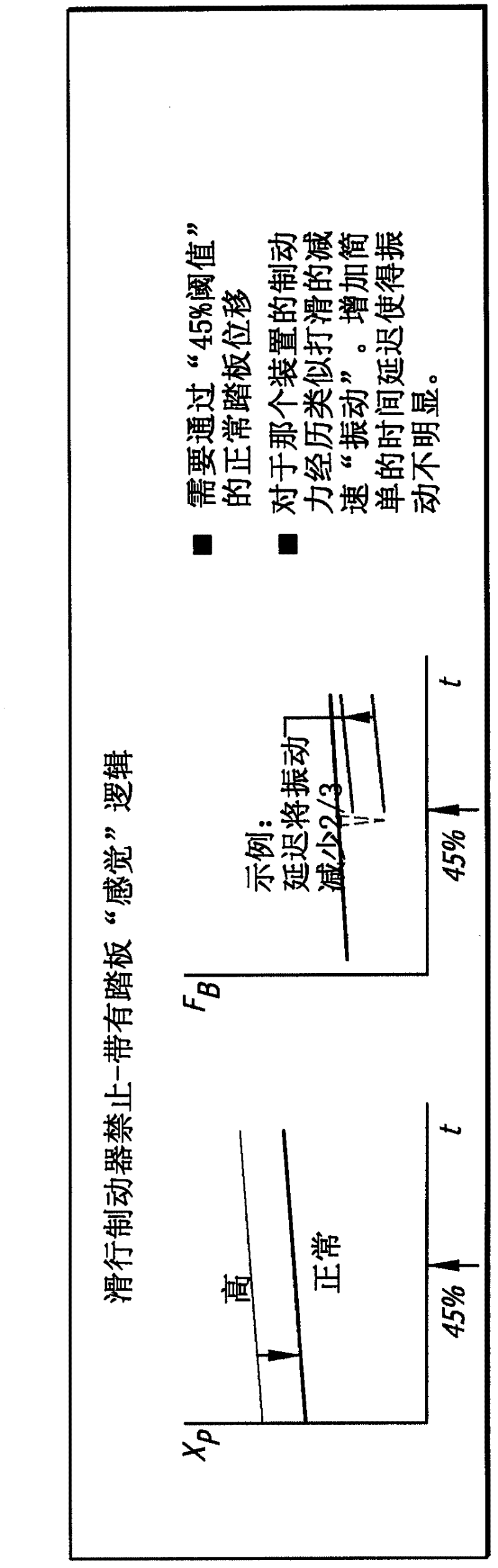

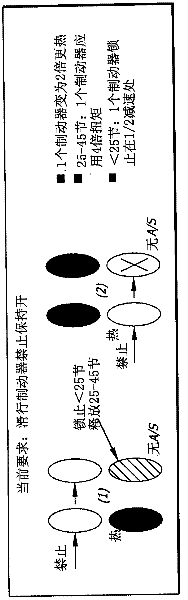

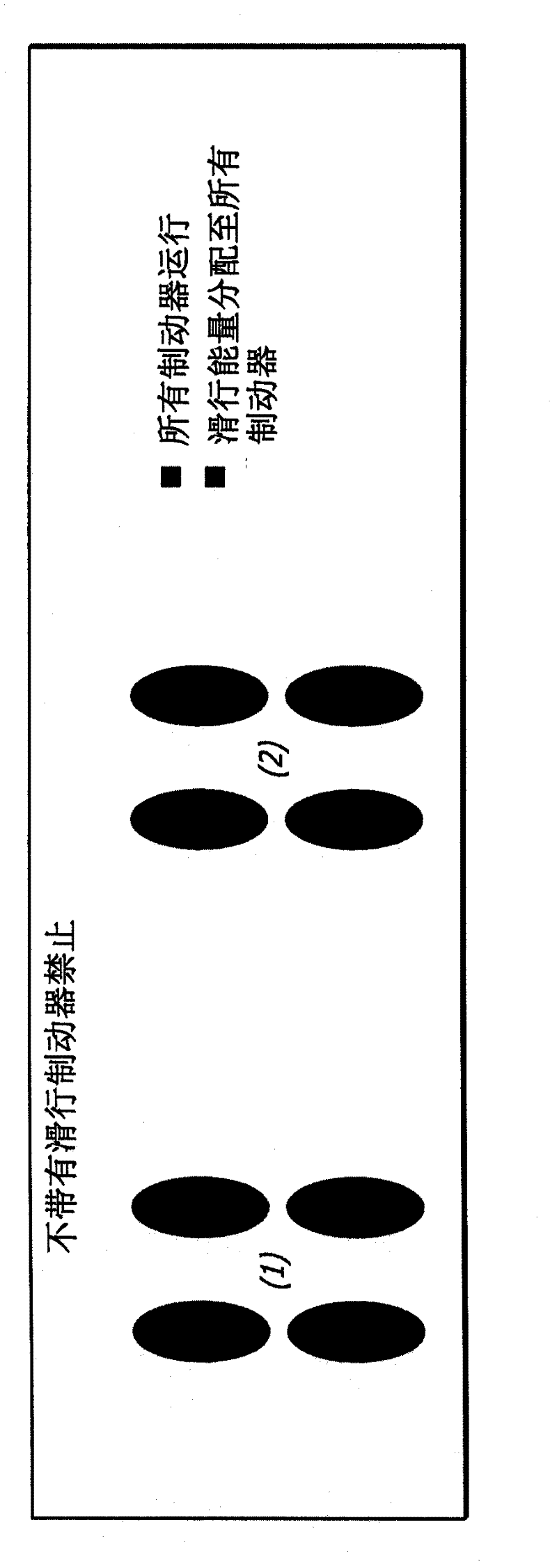

[0043] With reference to the drawings, which are provided by way of example and not by way of limitation, the present invention provides systems and methods for controlling a taxi brake inhibit mode of the brakes of an aircraft. refer to Figure 5 , the system 30 for controlling the taxi brake inhibit mode during operation of the aircraft brakes generally includes a brake system control unit (BSCU) 32 configured to control an electronic brake activation controller (EBAC) 34, the brake The system control unit is electrically connected with the electronic brake activation controller 34 through the system bus 36 . Further, the electronic brake activation controller is configured to control the operation of the landing gear, such as the operation of the landing gear 38, which includes the front wheel brake pair 40a, 40b connected to the electronic brake activation controller and the front wheel brake pair connected to the electronic brake activation controller. The pair of rear w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com