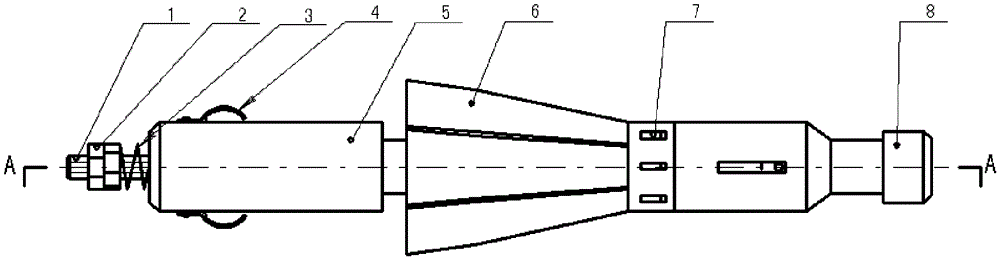

Temperature Controlled Umbrella Gas Lift Plunger

A plunger and gas lift technology, applied in devices for lifting liquids, temperature-controlled umbrella-type gas lift plunger. It can solve the problems of no technical solution in patents, no technical problems of temperature-controlled gas lift plunger, etc., and achieve the effect of improving work efficiency, wide application area and short cycle period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

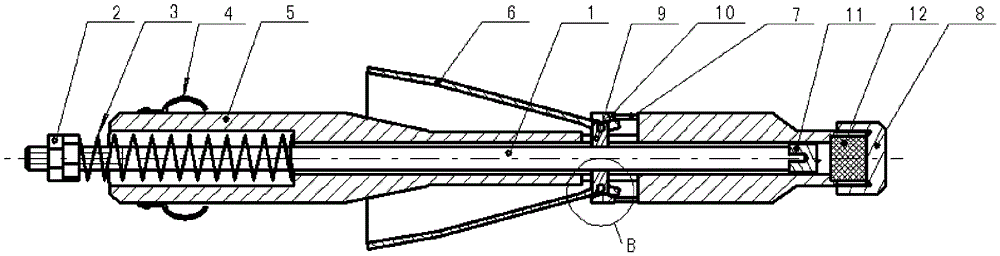

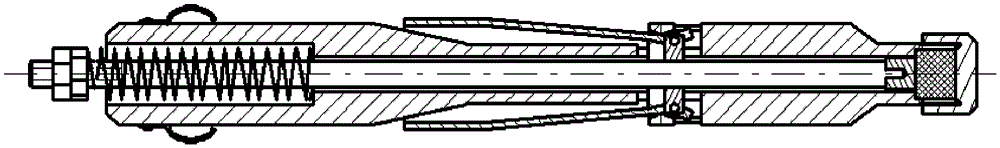

[0018] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings; the following embodiments are illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following embodiments.

[0019] The application principle of the present invention is: use the temperature and heat energy in the wellbore to cause thermal deformation of the material or magnetic change of the magnetic temperature material to control the opening and closing of the umbrella and provide energy for the opening and closing of the umbrella; when the plunger is down, Increase the difference between the cross-sectional area of the plunger and the inner cross-sectional area of the tubing; or in other words, when the plunger goes down, the cross-section of the plunger should be smaller, and the entire tubing section can be effectively blocked when the liquid is lifted, To prevent the liquid from slipping and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com