Vertical pile underpinning and pile hole sealing method of thick plate basic structure of building

A foundation structure and vertical pile technology, which is applied in foundation structure engineering, foundation structure repair, construction, etc., to achieve the effects of economical rationality, simple structure, and accelerated construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

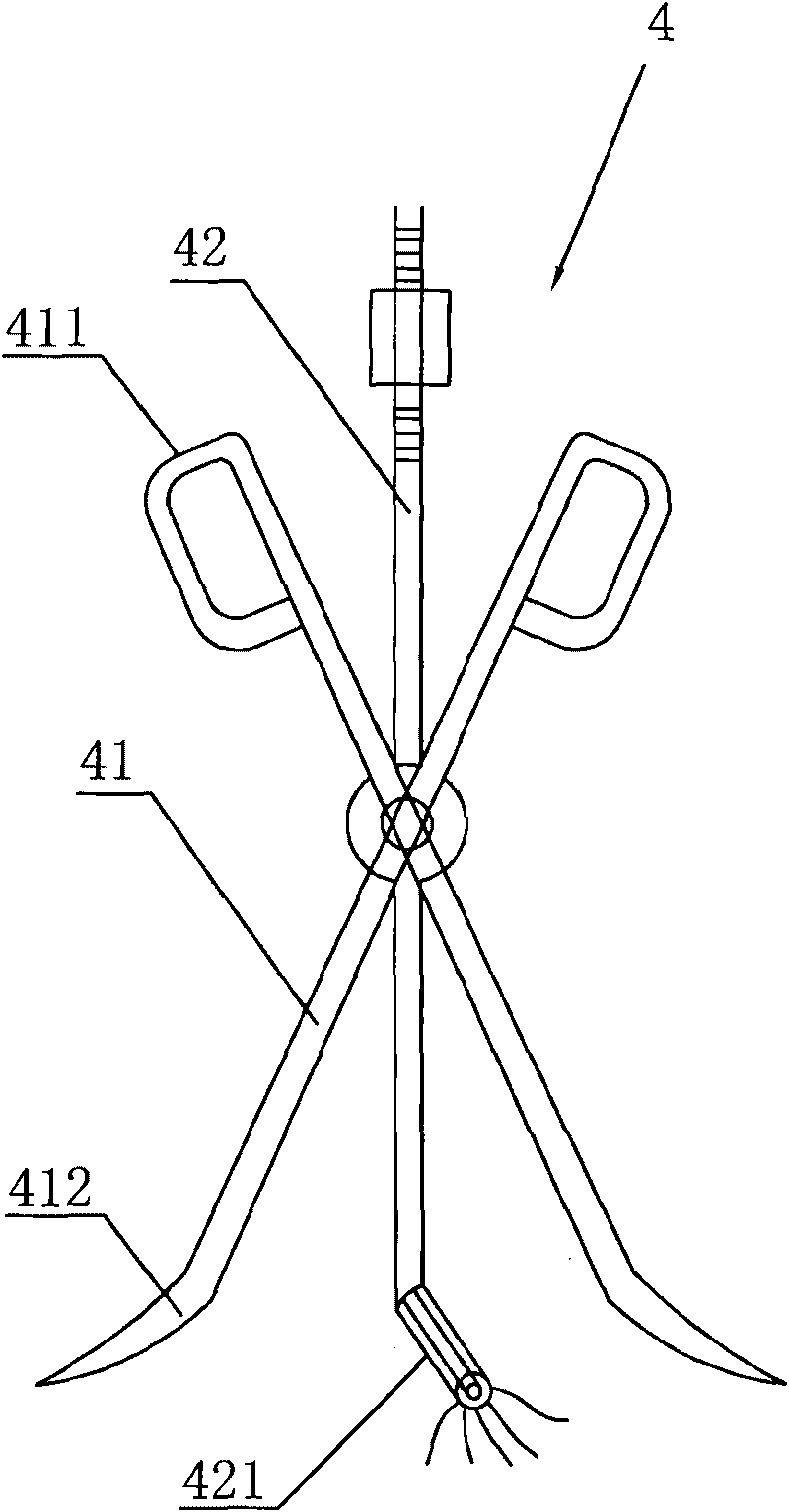

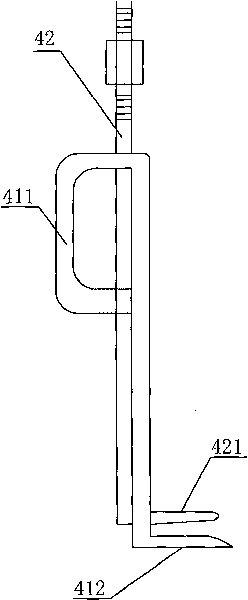

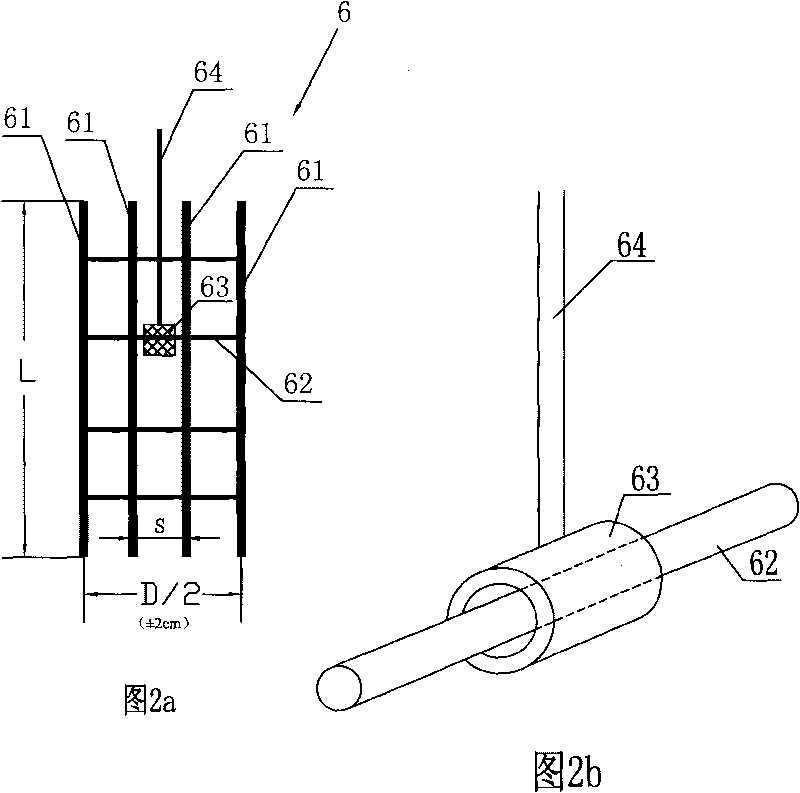

[0035] The specific operating process of the present invention's "vertical pile underpinning of building thick plate foundation structure and reinforcement method for sealing pile hole" is as follows:

[0036] (1) On the thick plate foundation 1, drill a vertical pile hole 2 with a machine tool, and form a pile 3 below the vertical pile hole 2. The pile 3 can be an anchor static pressure steel pipe pile, a reinforced concrete square pile or Pipe piles, or cast-in-place reinforced concrete piles.

[0037] According to the section size of the designed pile 3, on the thick slab foundation 1 (box foundation or raft foundation), the vertical pile hole 2 is drilled with a machine tool, and the aperture size of the vertical pile hole 2 is D=d+8~d+ 12cm, d is the diameter of the round pile or the side length of the square pile.

[0038] Then press or pour the pile body below the vertical pile hole 2, and the top of the pile 3 has a prefabricated steel backing plate 31. The thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com