Layered steam injection simulation test system and working method thereof

A simulation test system and layered steam injection technology, which is applied in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problem of uneven production of oil reservoirs, inability to produce new layers normally, and excessive steam absorption in high-permeability layers. and other problems to achieve the effect of accurate distribution of steam injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the following describes the embodiments of the present invention in further detail with reference to the accompanying drawings. Here, the exemplary embodiments of the present invention and the description thereof are used to explain the present invention, but not as a limitation to the present invention.

[0034] The stratified steam injection simulation test system in the embodiment of the present invention is suitable for the stratified steam distribution process test, and is a simulation test device designed according to the working principle and related parameters of the stratified steam injection and oil recovery of the oil field.

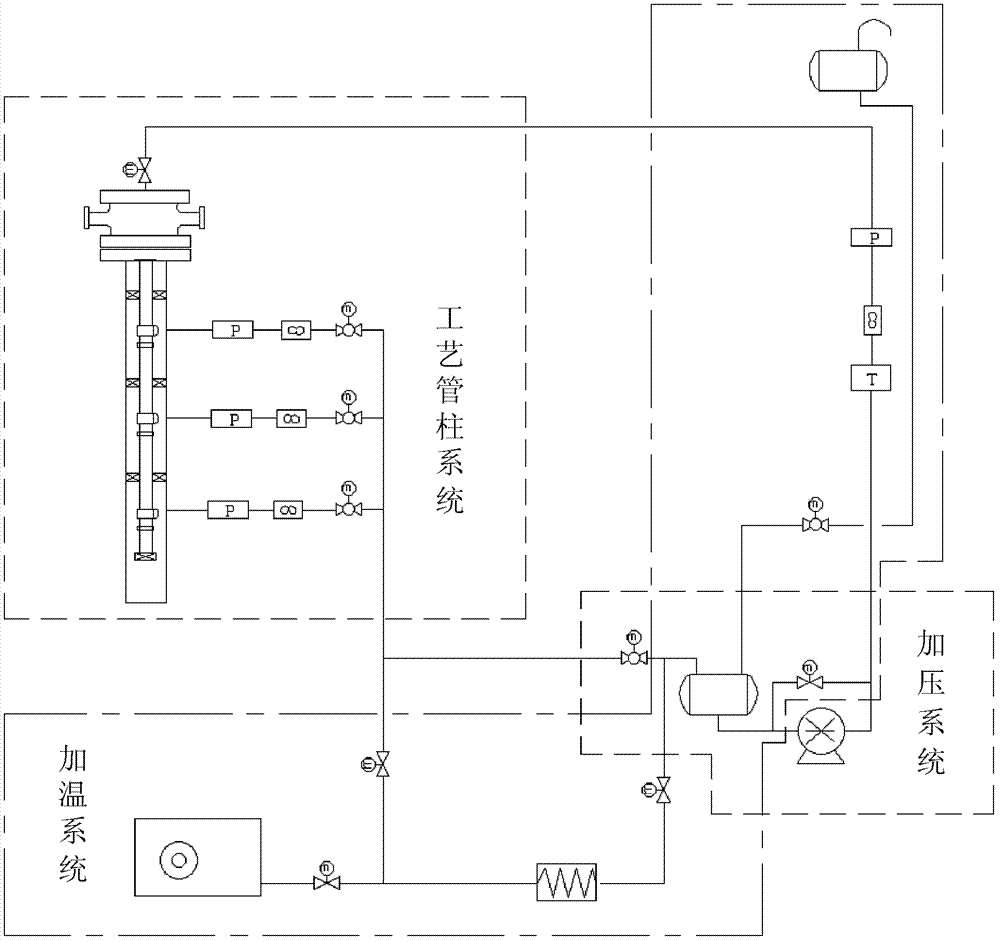

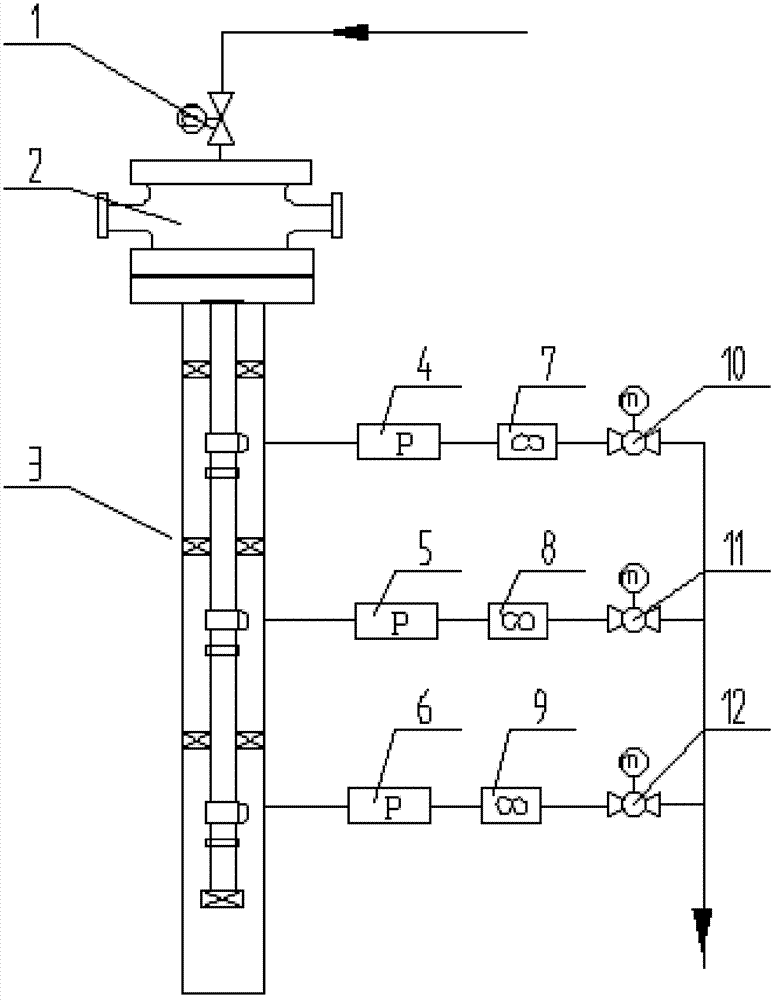

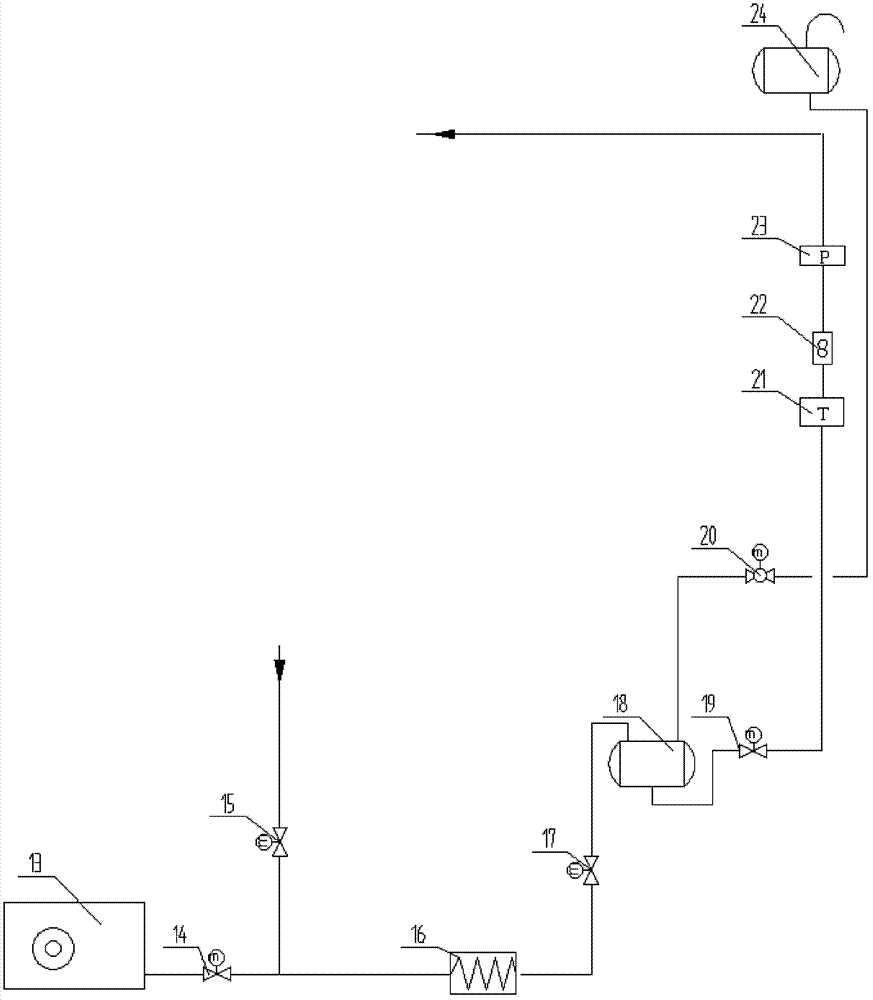

[0035] figure 1 It is a structural diagram of a layered steam injection simulation test system in an embodiment of the present invention. Such as figure 1 As shown, the layered steam injection simulation test system in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com