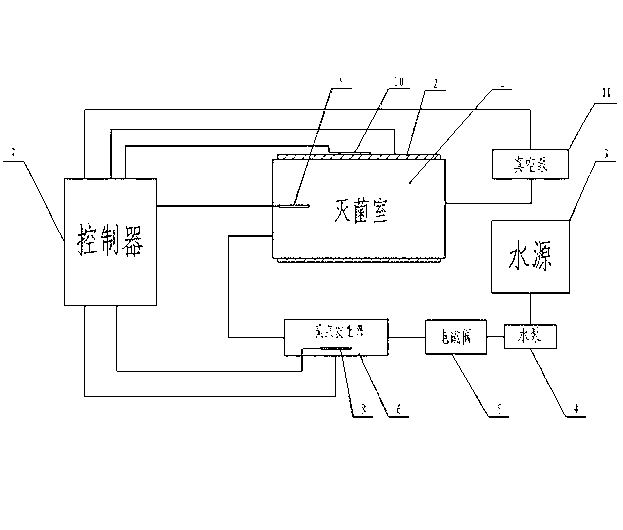

Heating control method for pressure steam sterilizer

A technology of heating control and pressure steam, which is applied to auxiliary controllers with auxiliary heating devices and temperature control by electric means, which can solve the problems of large temperature fluctuations, long operation time, and no steam generated by the steam generator. , to achieve the effect of small temperature fluctuation, avoiding no steam for a long time, and avoiding supersaturated steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

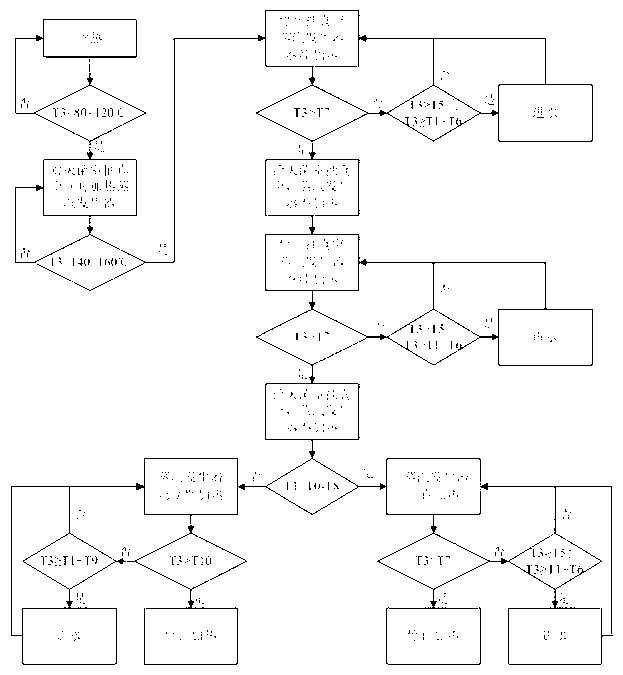

[0023] Example 1: A heating control method for a pressure steam sterilizer, the working temperature T0 set by the sterilizer is 134°C, the temperature in the sterilization chamber 1 detected by the temperature sensor 9 is T1, and the temperature sensor 10 detects The temperature of the outer wall of the sterilization chamber 1 is T2, the temperature inside the steam generator 6 detected by the temperature sensor 8 is T3, and the set temperature is T4=10°C, T5=100°C, T6=20°C, T7=165°C , T8=5℃, T9=6℃, T10=155℃;

[0024] The heating method comprises the following steps:

[0025] 1) Heating control of heating element 2 on the wall of the sterilization chamber:

[0026] a) If T2≤T0-T4, that is, T2≤124°C, the controller 7 controls the heating element 2 on the outer wall of the sterilization chamber to energize periodically, the energization period is 2s, and the duty ratio is 0.5, that is, energization is 1s in one cycle, Power off for 1s;

[0027] b) If T2>T0-T4, that is, T2>124...

Embodiment 2

[0037] Example 2: A heating control method for a pressure steam sterilizer, the working temperature T0 set by the sterilizer is 127°C, the temperature in the sterilization chamber 1 detected by the temperature sensor 9 is T1, and the temperature sensor 10 detects The temperature of the outer wall of the sterilization chamber 1 is T2, the temperature inside the steam generator 6 detected by the temperature sensor 8 is T3, the set temperature is T4=6°C, T5=110°C, T6=14°C, T7=155°C, T8=8℃, T9=7℃, T10=160℃;

[0038] The heating control method comprises the following steps:

[0039] 1) Heating control of heating element 2 on the wall of the sterilization chamber:

[0040] a) If T2≤T0-T4, that is, T2≤121°C, the controller 7 controls the heating element 2 on the outer wall of the sterilization chamber to energize periodically, the energization period is 1s, and the duty ratio is 0.4, that is, energization is 0.4s in one cycle , power off for 0.6s;

[0041] b) If T2﹥T0-T4, that is,...

Embodiment 3

[0051] Example 3: A heating control method for a pressure steam sterilizer, the working temperature T0 set by the sterilizer is 105°C, the temperature in the sterilization chamber 1 detected by the temperature sensor 9 is T1, and the temperature sensor 10 detects The temperature of the outer wall of the sterilization chamber 1 is T2, the temperature inside the steam generator 6 detected by the temperature sensor 8 is T3, and the set temperature is T4=0°C, T5=120°C, T6=6°C, T7=180°C, T8=10℃, T9=10℃, T10=150℃, including the following steps:

[0052] 1) Heating control of heating element 2 on the wall of the sterilization chamber:

[0053] a) If T2≤T0-T4, that is, T2≤105°C, the controller 7 controls the heating element 2 on the outer wall of the sterilization chamber to be energized periodically, the energization period is 2s, and the duty ratio is 1, that is, it is always energized;

[0054] b) If T2﹥T0-T4, that is, T2﹥105°C, the controller 7 controls the heating element 2 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com