Guide beam device of bar milling machine

A technology for bar rolling mills and beams, applied in the field of guide beam devices for bar mills, can solve problems such as unstable rolling process and loose guide beam devices, and facilitate maintenance and maintenance, reduce production costs, and prepare costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

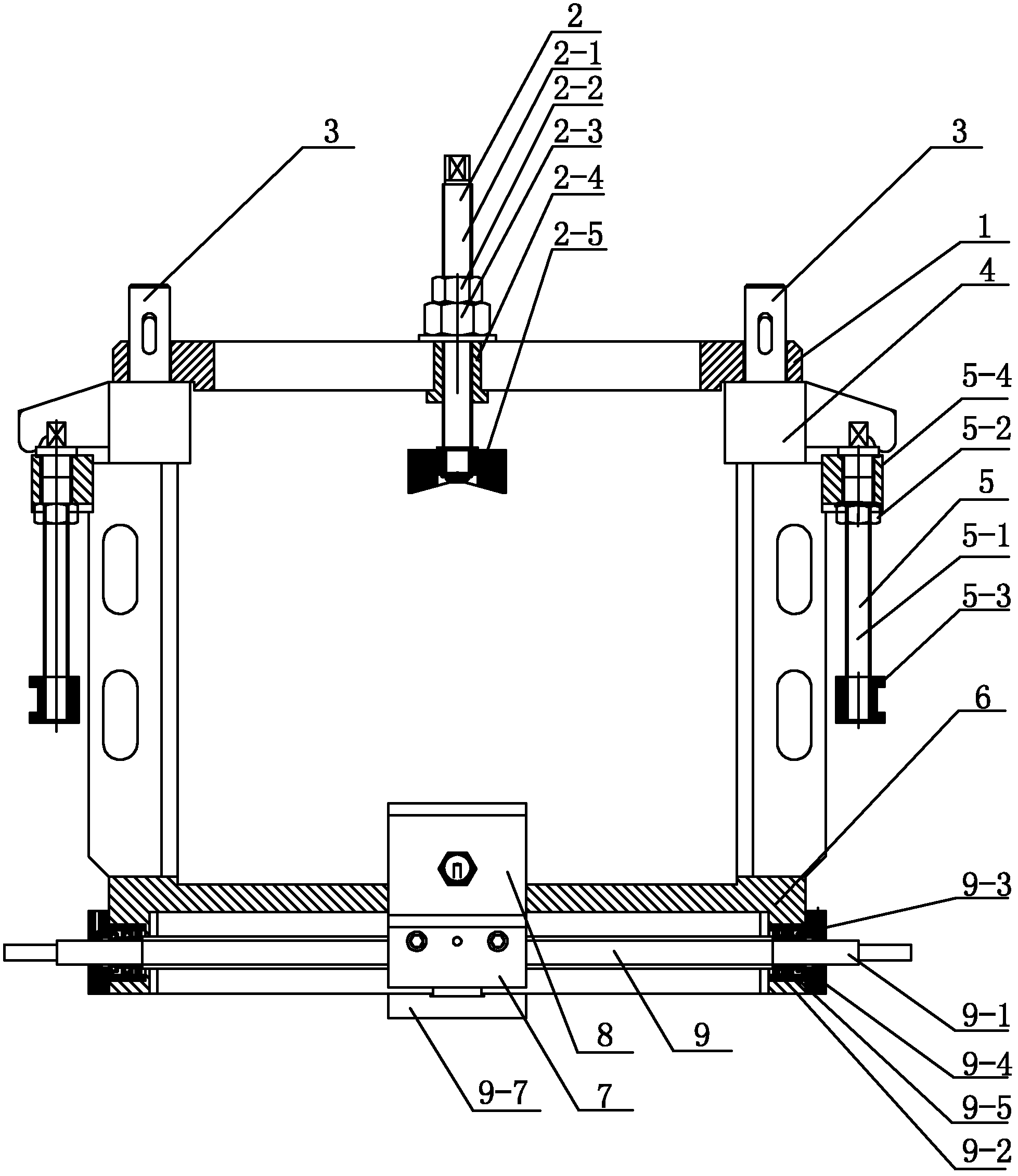

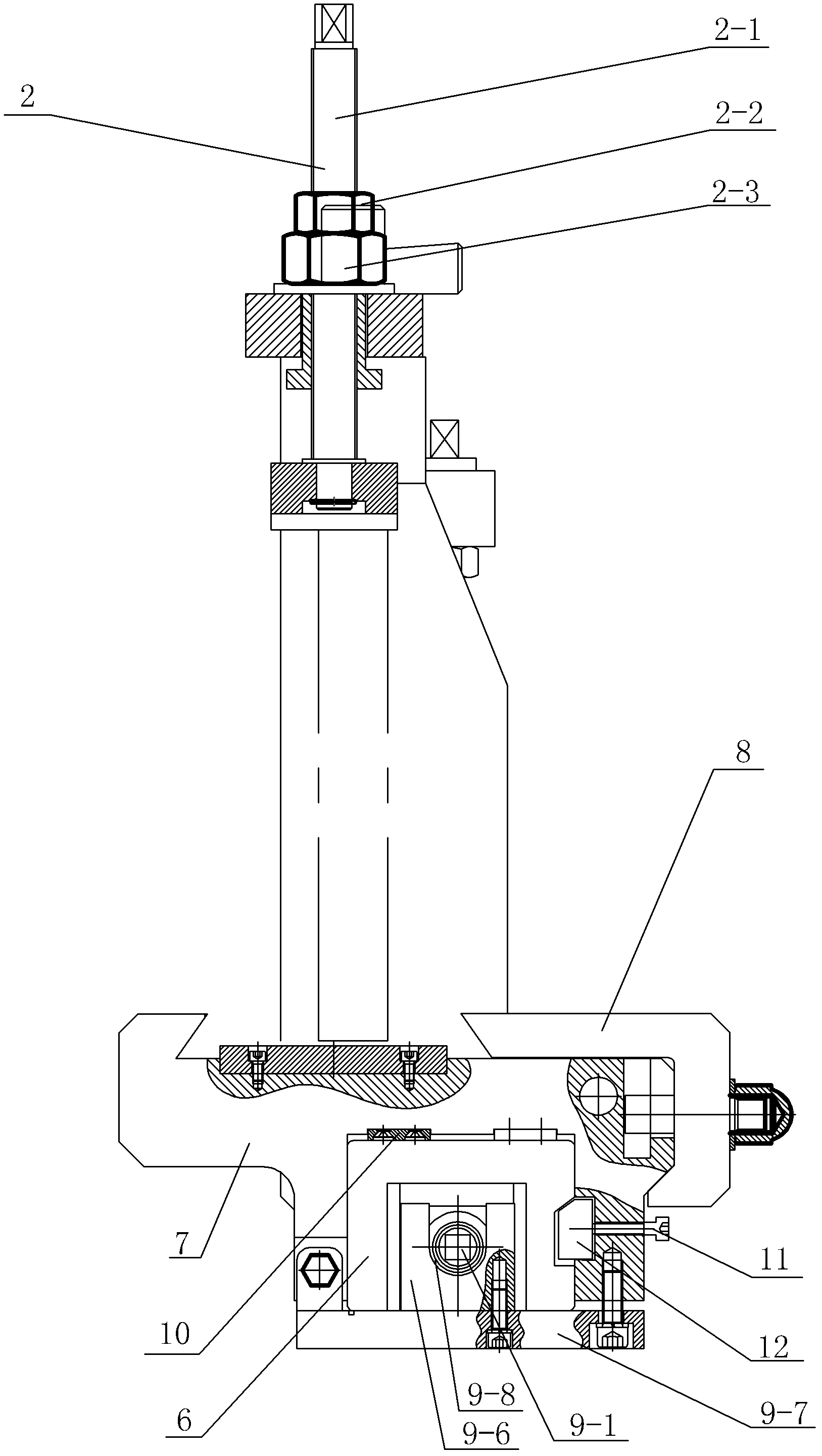

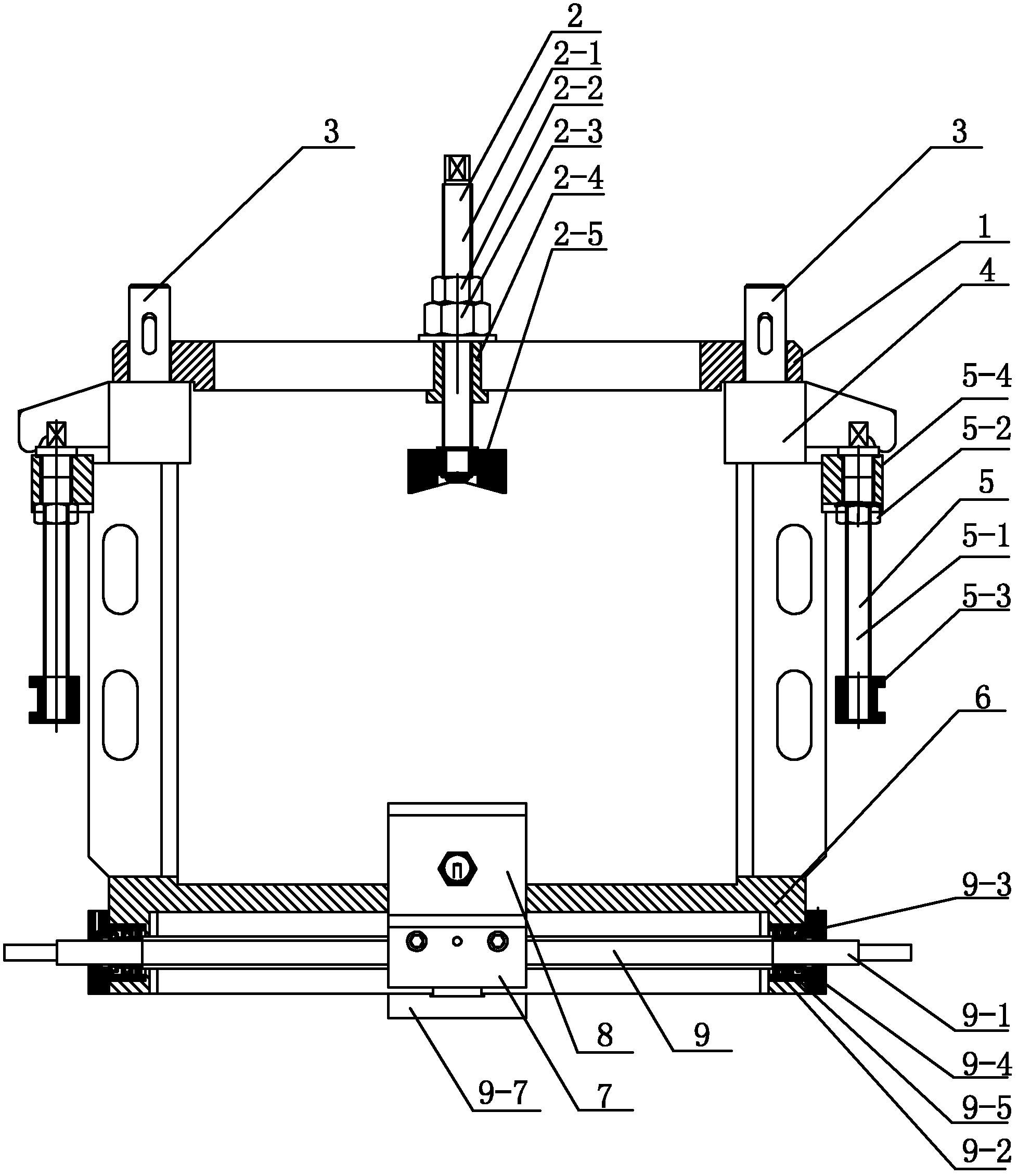

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a guide beam device for a bar rolling mill described in this embodiment includes an upper beam 1, a pressing assembly 2, two pull rods 3, two guide brackets 4, a lower beam 6, and a slide rail 7 , splint 8 and sliding lead screw assembly 9, the two ends of described upper beam 1 are respectively connected with the upper end of a pull rod 3, the two ends of described lower beam 6 are respectively connected with the lower end of a pull rod 3, described upper beam 1, The lower beam 6 and the two pull rods 3 constitute a four-frame body, and each guide bracket 4 is respectively set on a pull rod 3, and the two guide brackets 4 can support the upper beam 11 to move up and down along the pull rod 3. The pressing assembly 2 is installed in the middle of the upper beam 1, the lower beam 6 is installed in the groove on the lower surface of the slide rail 7, the splint 8 is installed on th...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 This embodiment is described. An adjustment assembly 5 is installed on each pull rod 3 of a guide beam device for a bar rolling mill described in this embodiment, and each adjustment assembly 5 includes an adjustment screw rod 5-1 and a nut 5-2. , adjust the copper block 5-3 and the mounting seat 5-4, the mounting seat 5-4 is fixedly installed on the outer wall of the pull rod 3, and the mounting seat 5-4 is located below the guide bracket 4, the adjusting wire The upper end of the rod 5-1 passes through the mounting base 5-4 and is connected with the guide bracket 4, the nut 5-2 is sleeved on the adjusting screw rod 5-1, and the nut 5-2 is connected to the bottom of the mounting base 5-4. The surface is fixed, and the adjustment copper block 5-3 is sleeved on the lower end of the adjustment screw rod 5-1. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 Describe this embodiment, the compression assembly 2 of a guide beam device for a bar rolling mill described in this embodiment includes a screw rod 2-1, a first nut 2-2, a second nut 2-3, an adjustment sleeve 2-4 and brake block 2-5, the adjustment sleeve 2-4 is inserted in the middle of the upper beam 1, and the lower end of the screw rod 2-1 passes through the adjustment sleeve 2-4 and the brake block 2 -5 connection, the first nut 2-2 and the second nut 2-3 are sequentially set on the screw rod 2-1 from top to bottom, and the first nut 2-2 and the second nut 2-3 are located On the upper surface of the upper beam 1. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com