Angle amplification parallel mechanism

A technology of angle magnification and parallel connection, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as small workspace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

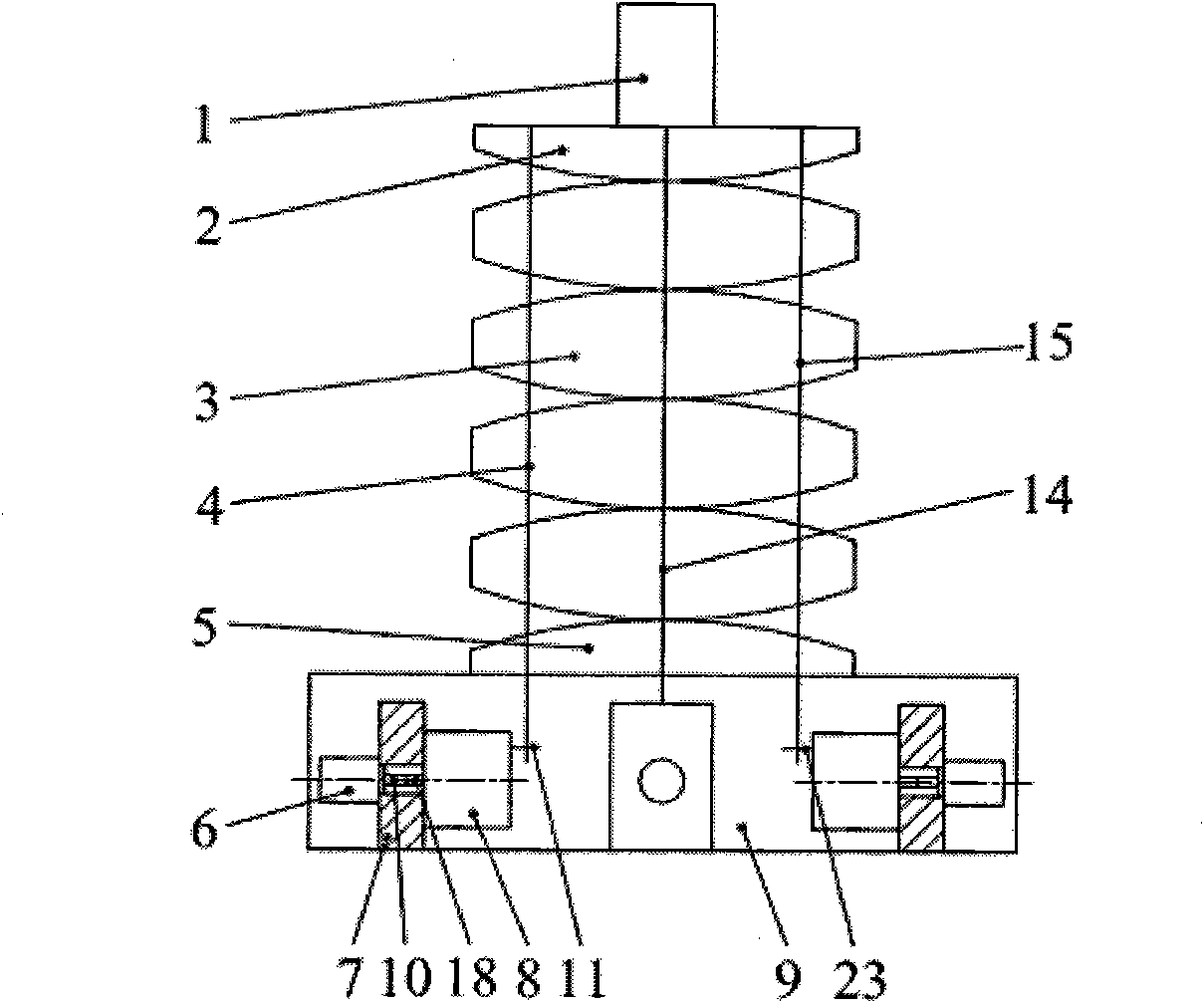

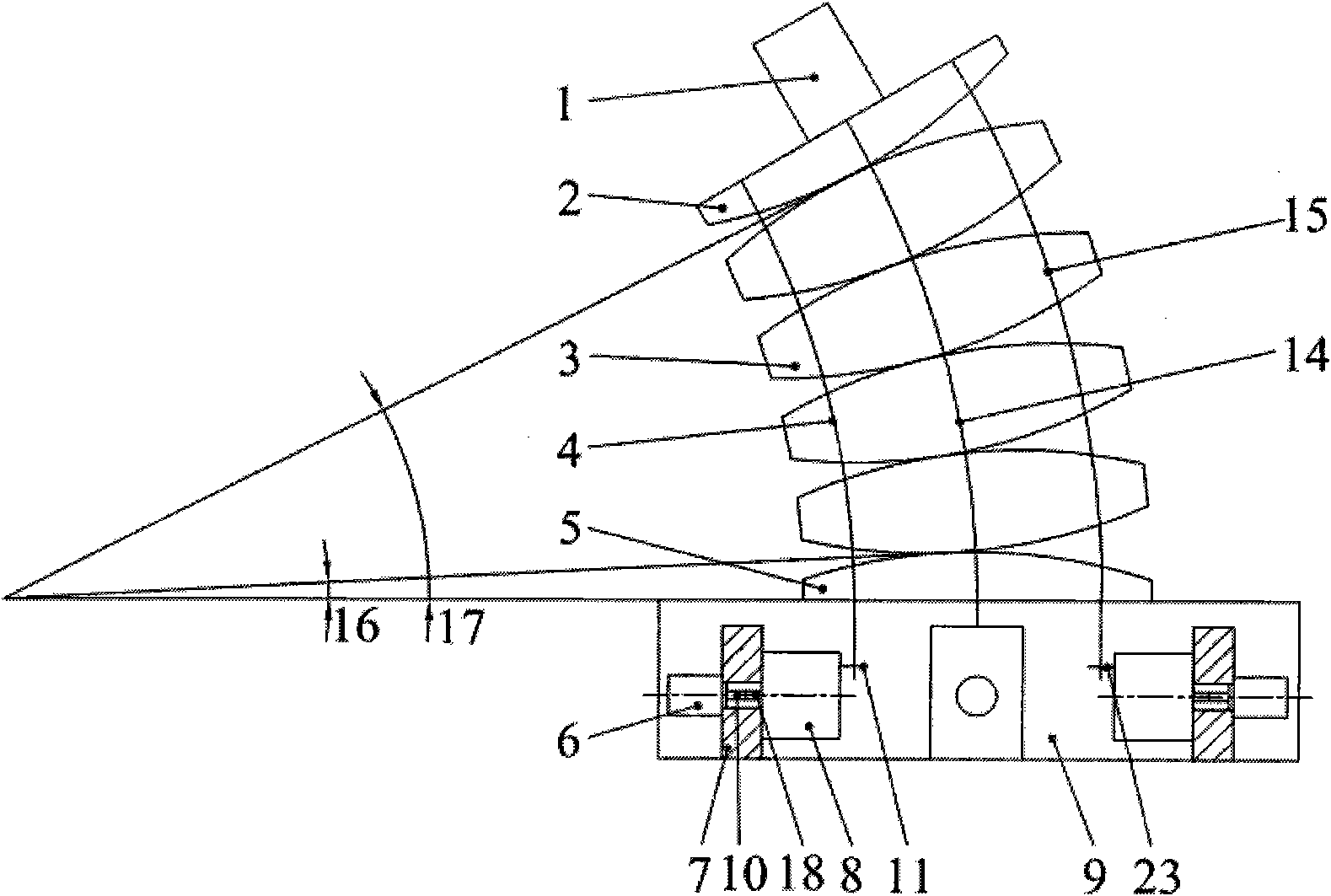

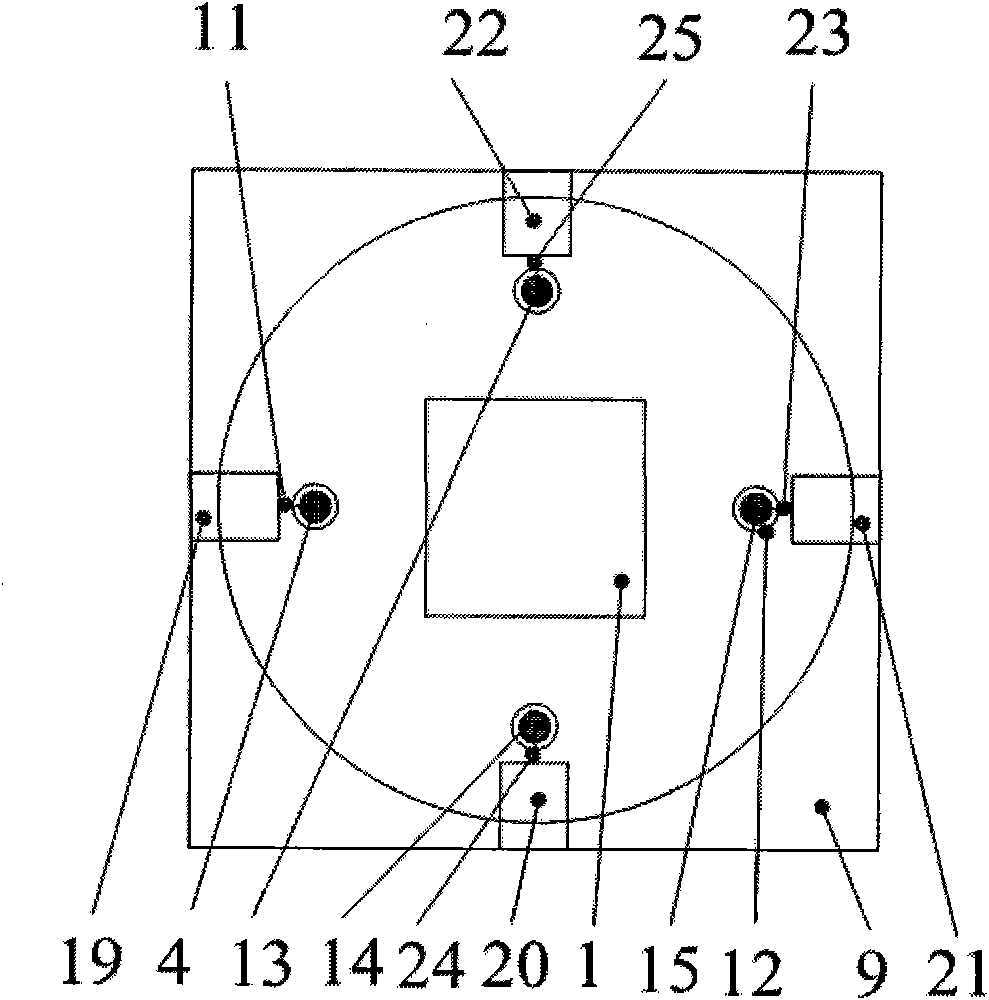

[0015] like figure 1 , figure 2 , image 3 Shown:

[0016] The angle magnifying parallel mechanism of the present invention includes a transmission mechanism and a driving mechanism. The transmission mechanism is composed of an upper platform 2, a plurality of intermediate transmission bodies 3 and a lower platform 5. There are four drive mechanisms, respectively left drive mechanism 19, front drive mechanism 20, right drive mechanism 21, rear drive mechanism 22, and their structure is identical; The reducer is composed of 8.

[0017] Its positional relationship is:

[0018] The upper platform 2 installs or places the object 1, and the lower platform 5 is connected with the fixed seat 9; the upper edge of the upper platform 2, the lower platform 5 and the middle transmission body 3 are all provided with a plurality of flexible cable holes 12 uniformly distributed along the circumferential direction; The structure of the mechanism is the same, and the left drive mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com