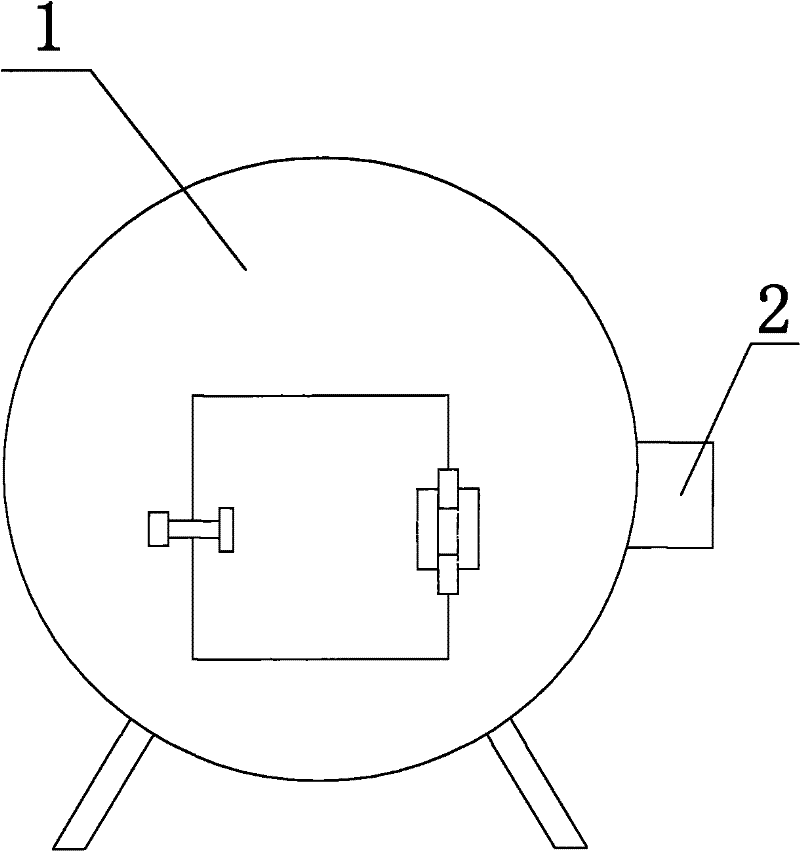

Warp setting steam boiler

A steam furnace and warp technology, which is used in textiles and papermaking, etc., can solve the problems of no temperature reminder device, poor warp setting effect, warp deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

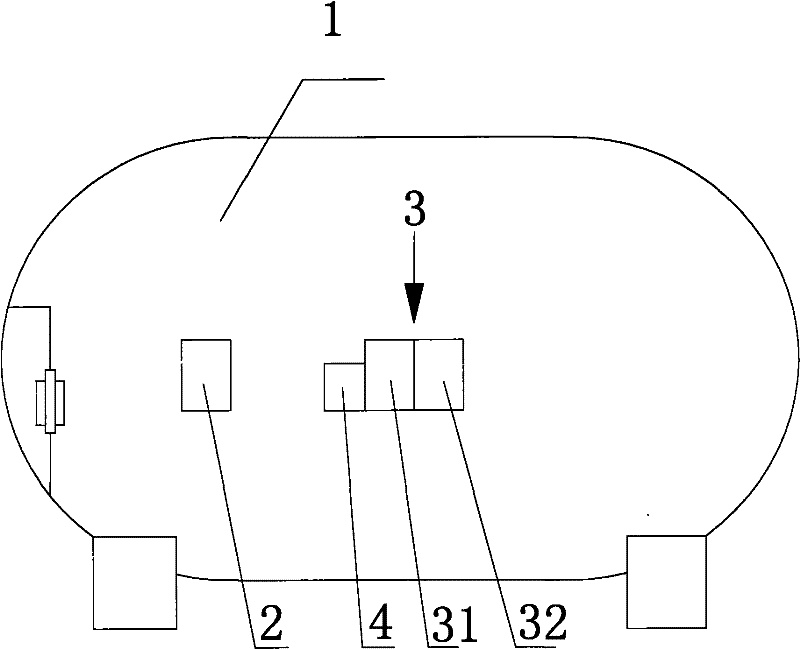

[0011] The preferred specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0012] Such as figure 2 As shown, the warp-shaped steam oven includes a furnace body 1, an electronic thermometer 2 installed on the outer wall of the furnace body 1, a temperature sensing device 4 arranged on the furnace body, and an alarm device 3 connected to the temperature sensing device 4.

[0013] The alarm device 3 includes a sound alarm 31 and a light alarm 32, and when the warp is heated for shaping, the temperature in the furnace is controlled within 100°C. When the temperature sensing device 4 senses that the temperature in the furnace is higher than 100°C, the temperature sensing device 4 converts the temperature into an electrical signal to activate the sound alarm 31 and the light alarm 32, and the sound alarm 31 and the light alarm 32 can issue an alarm in time Remind the workers to control the temperature in the body of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com