Machine body of disk type separation machine

A disc separator and fuselage technology, applied in the field of disc separators, can solve problems such as damage to bearing vertical shafts, blockage of bearings, vertical shafts, hidden safety hazards, etc., to reduce maintenance times, improve work efficiency, and work lastingly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with embodiment the present invention is described in further detail.

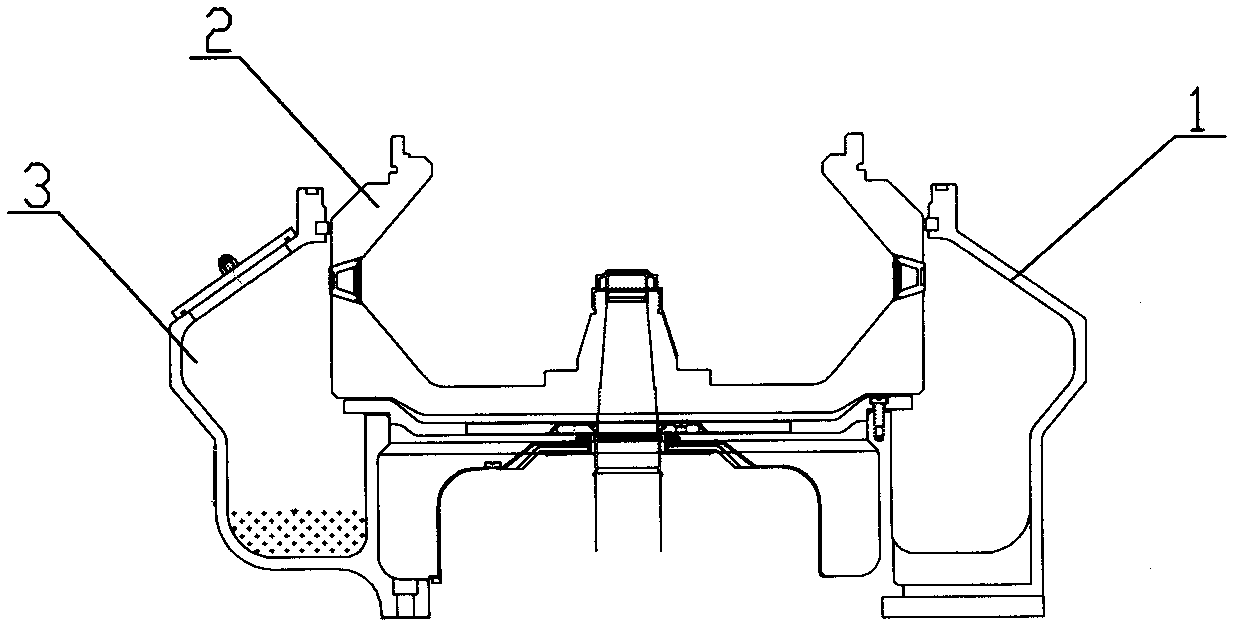

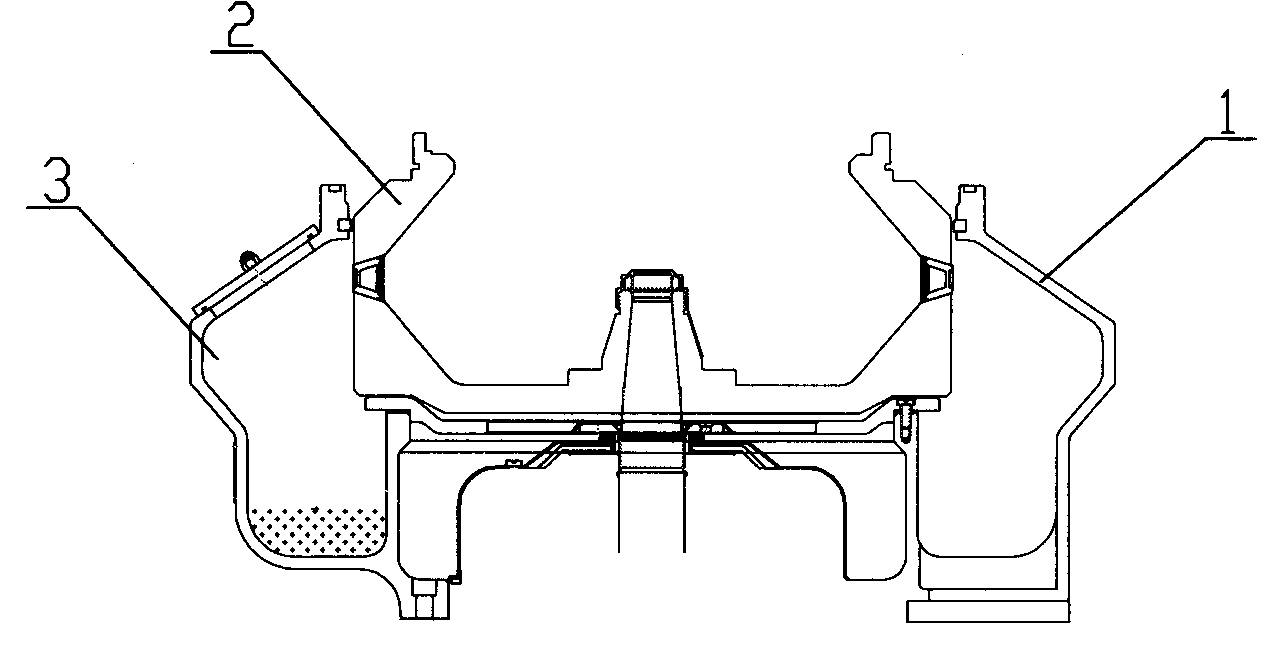

[0008] Depend on figure 1 It can be seen that the fuselage of a disc separator according to the present invention is: the inner side of the fuselage 1 corresponding to the overflow slag liquid sprayed from the slag outlet of the drum 2 in the cavity on the upper part of the fuselage 1 There is a circle of grooves 3 on the wall, and the position of the grooves 3 on the inner wall of the upper part of the fuselage 1 is exactly the position of the inner wall of the upper part of the fuselage 1 where the overflow slag liquid sprayed by the drum 2 from the slag discharge port is sprayed. When the disc separator is working, the overflow slag sprayed from the slag outlet of the drum 2 changes the direction of the reflected flow in the groove 3 on the inner wall of the fuselage 1 and directly enters the bottom of the cavity of the fuselage 1. The drum 2 in the upper cavity of the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com