Array substrate, manufacturing method thereof, display panel and display device

A technology for an array substrate and a substrate substrate, which is applied to display panels and display devices, and a manufacturing method thereof, in the field of array substrates, can solve the problems of color separation of reflected light, affecting users' experience of absolute black images, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

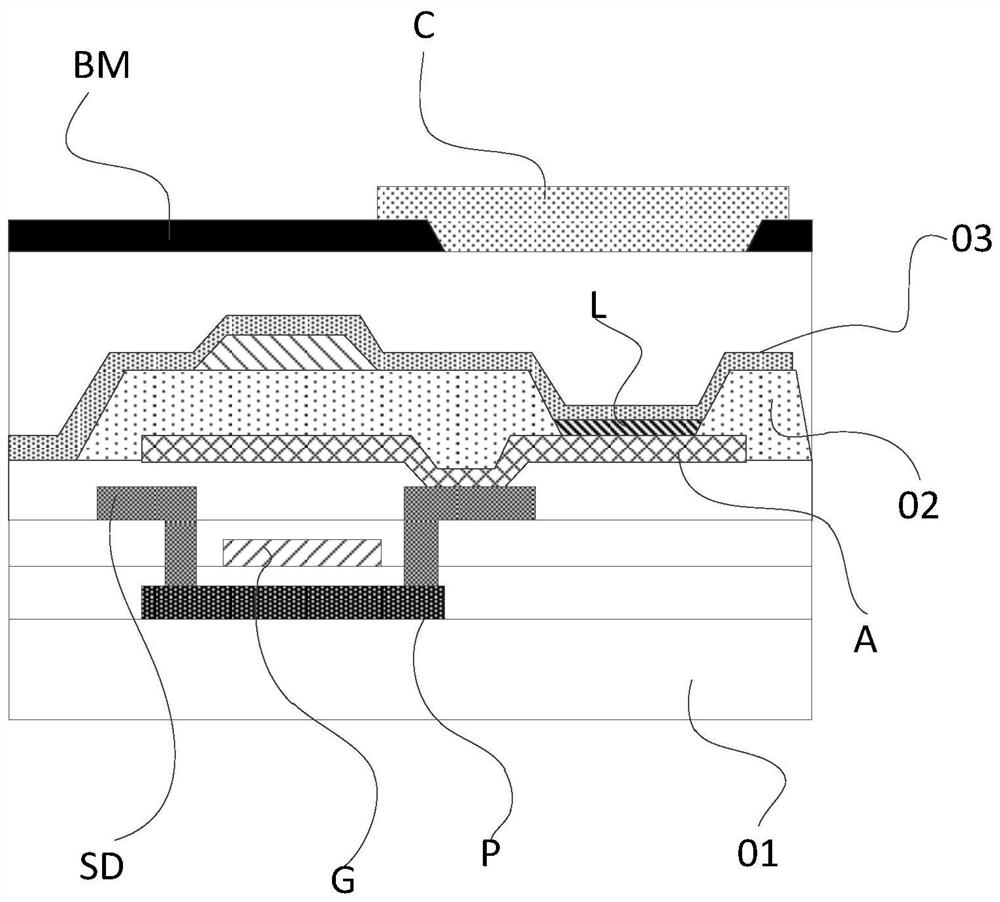

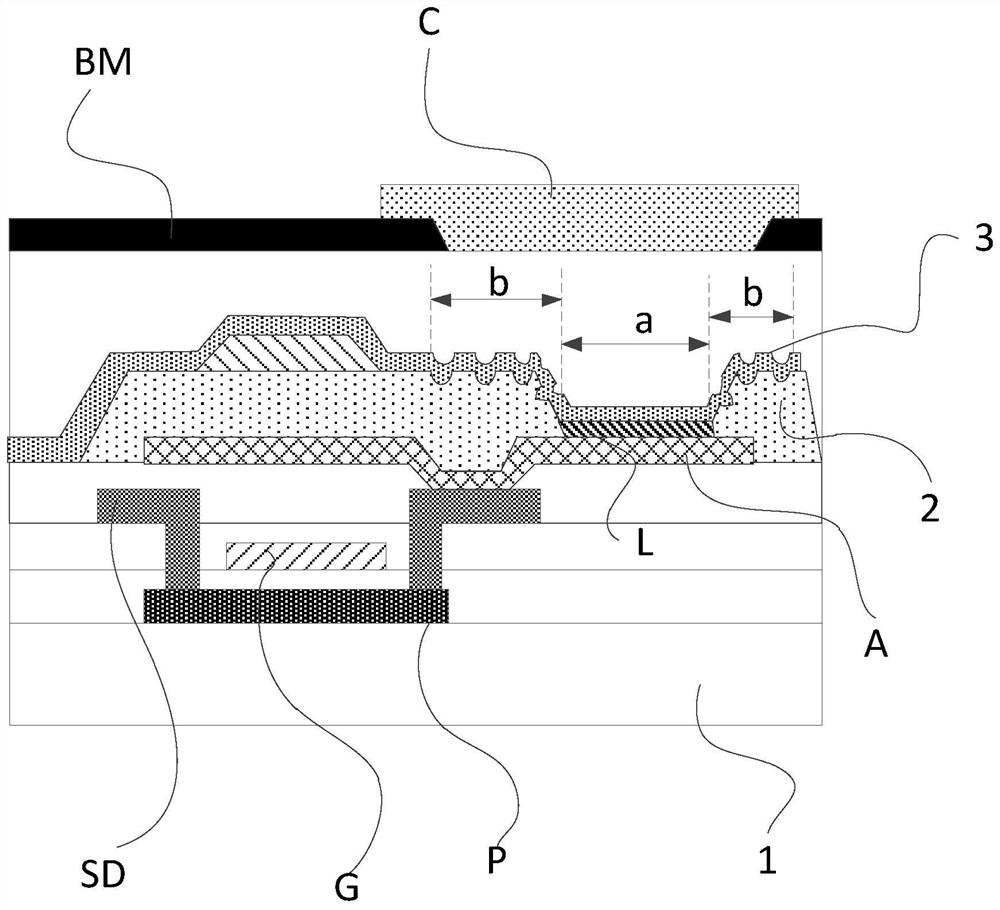

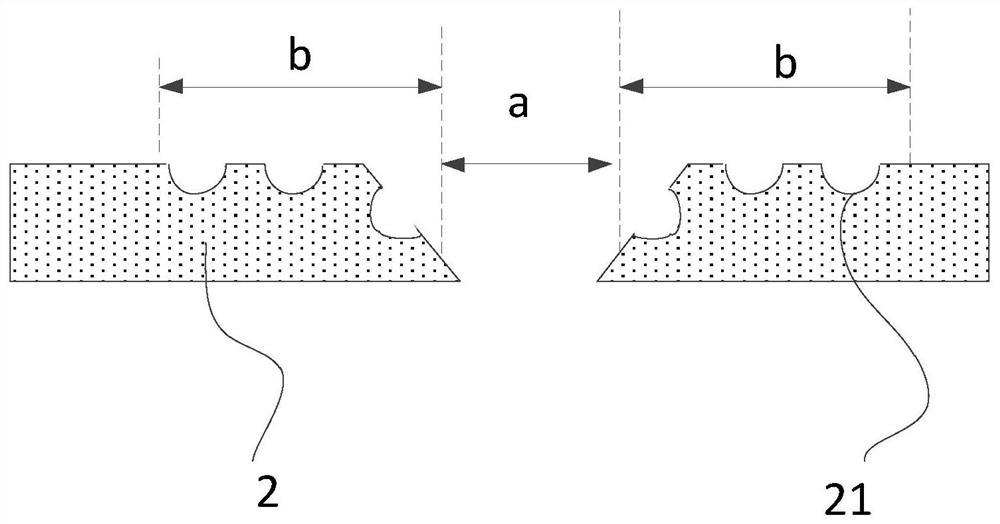

[0046] The structure of the array substrate in the related art is as figure 1As shown, it includes: a base substrate 01, a pixel driving circuit (including a semiconductor layer P, a gate layer G and a source-drain electrode layer SD) located on the base substrate 01, and an anode layer A electrically connected to the pixel driving circuit. , the pixel defining layer 02 on the anode layer A, the pixel defining layer 02 has an opening area, the light-emitting layer L is located in the opening area, the cathode layer 03 covers the entire surface of the pixel defining layer 02 and the opening area, and the cathode layer 03 is away from the substrate One side of the base substrate 01 is further provided with a black matrix layer BM and a color filter C, and the color filter C is arranged in one-to-one correspondence with the opening area. For such as figure 1 In the structure of the array substrate shown, since there is no circular polarizer, when the screen is turned off, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com