Gear rack type self-locking rope clip

A rack-and-pinion and cable-holding device technology, which is applied in the field of automobile crash test devices, can solve problems such as troublesome operation, complex structure, and small locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

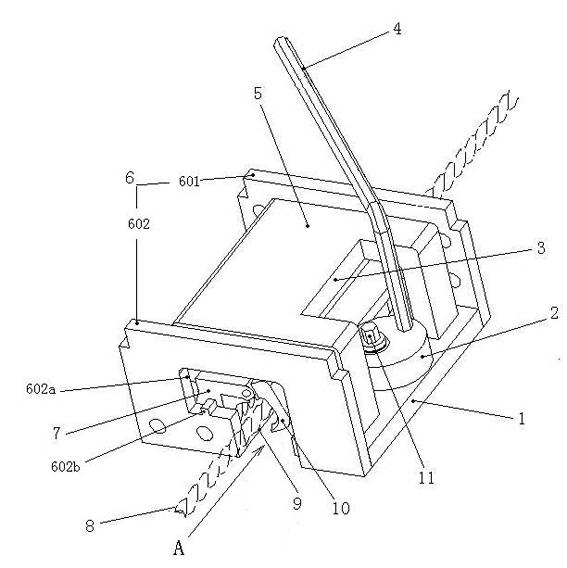

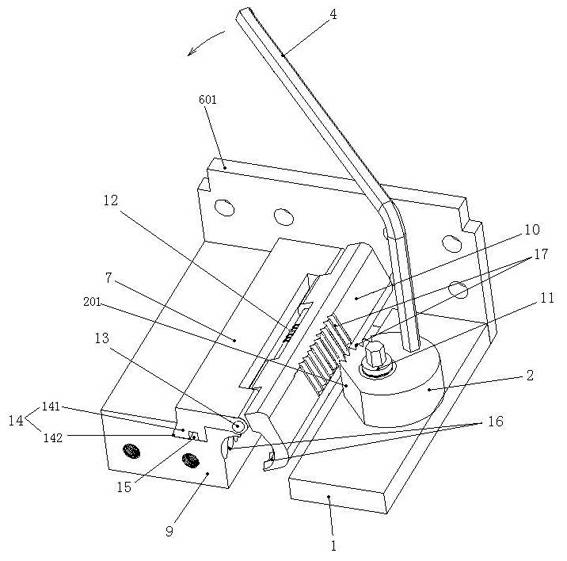

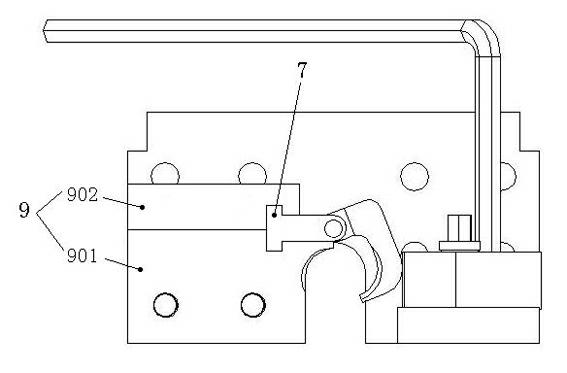

[0015] See figure 1 , figure 2 , the rack and pinion type self-locking grip rope device, including a base, the base includes a left base 9 and a right base 1, and the left and right bases 9, 1 are connected together to form an integral connection plate 6; the connection plate 6 is divided into upper and lower connections Plates 601, 602; a through opening A is formed between the left and right bases 9 and 1 bottoms, and the left base 9 on one side along the direction of the through opening A is provided with a hinge slider 7 sliding in this direction; the hinge slider 7 and The left base 9 is connected by a dovetail rail chute structure 14, the left base 9 is provided with a dovetail groove 14, and the bottom of the hinge slider 7 is provided with a dovetail slide rail 141 to cooperate with the dovetail groove 141 on the left base 9; the hinge slider The dovetail slide rail 141 of 7 is provided with a limit hole 15; the hinge slider 7 is hinged with a long pin 13 to have a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com