Film printer

A printing machine and film technology, applied in printing equipment, printing equipment, optics, etc., can solve problems such as low efficiency and character font restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

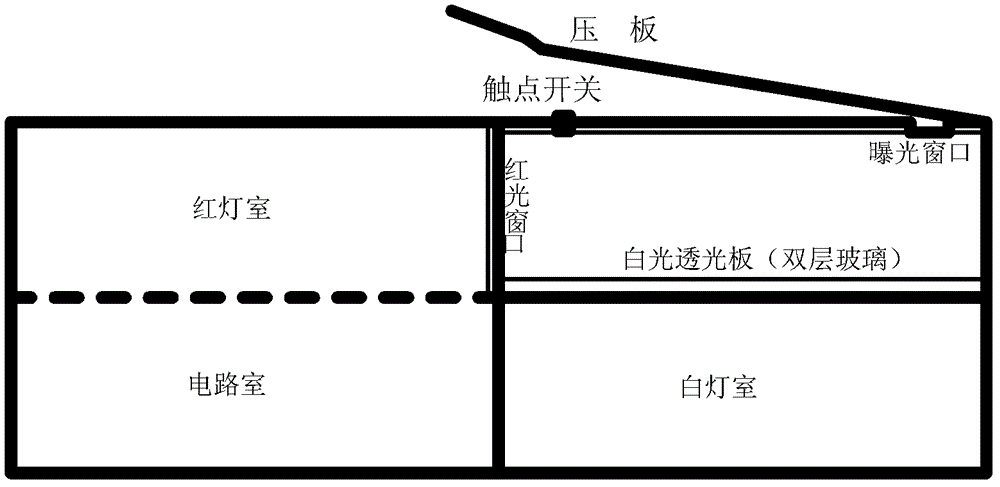

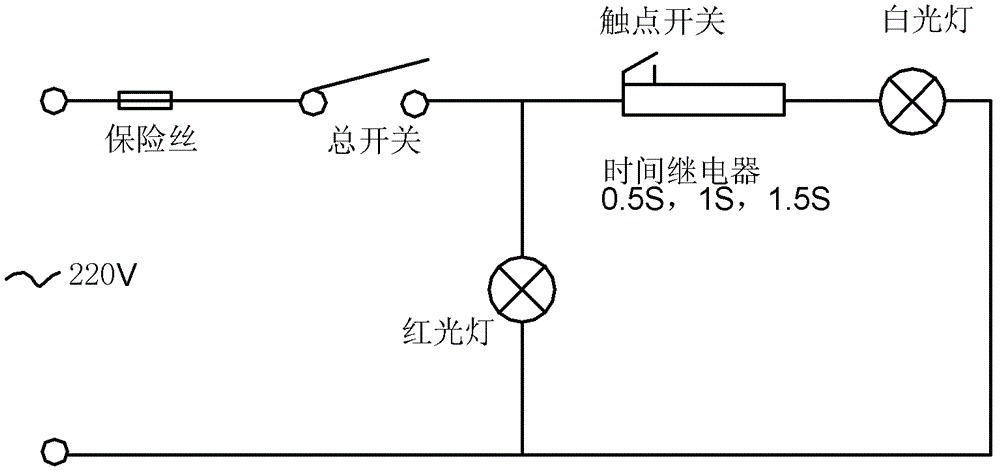

[0009] According to the requirements of GJB, the part number, part batch number, part serial number, and date of transillumination are required to be marked on the fluoroscopy negative. At present, most of them use small lead characters on the film when exposing the film, but this method is efficient. Low, and the placement of fonts is also very limited. The present invention specifically studies the above-mentioned defects, and obtains a film printing machine which can transfer the characters on the paper to the film used for radiographic inspection, and can make permanent marks on the negative film. like figure 1 As shown, the entire film printer is a rectangular box structure, which is divided into a red light room, a white light room, a circuit room and an exposure room. The red light room is located above the circuit room, and the two rooms communicate with each other; the white light room is located below the exposure room, and a white light-transmitting plate is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com