Spray mixing tank for dry powder fire extinguishment

A dry powder fire extinguishing and tank technology, which is applied in fire rescue and other directions, can solve the problems of inability to play a role in fire fighting, inability to reach users, and unsatisfactory fire extinguishing effect, and achieves a technology that reduces manufacturing difficulty, facilitates manufacturing and improves efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

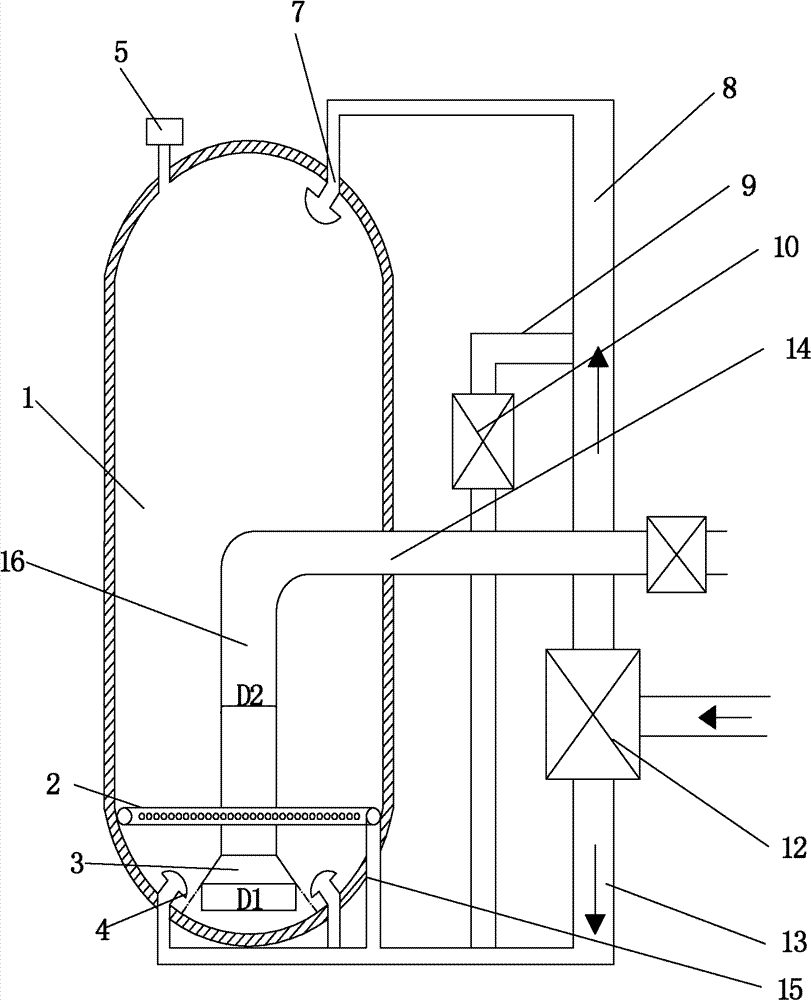

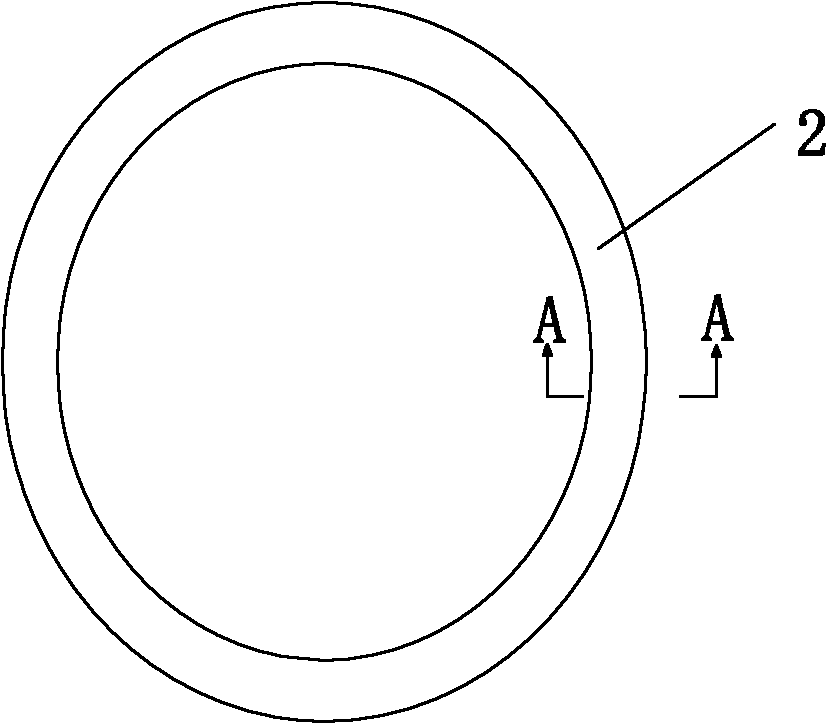

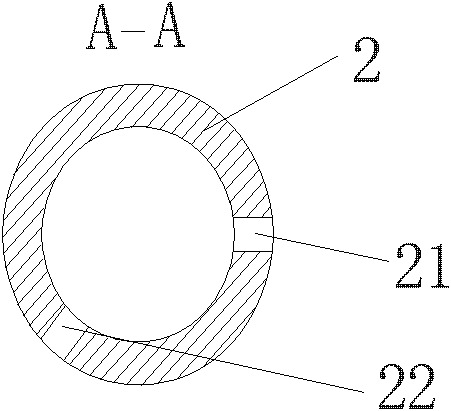

[0027] Such as figure 1 The mist mixing tank for dry powder fire extinguishing shown includes a mist mixing tank body 1, a powder outlet 14 is arranged on the side wall of the mist mixing tank body, and the top of the mist mixing tank body 1 is also provided with a pressure The pressure detector 5 for detection, the top and bottom of the mist mixing tank 1 are respectively provided with an upper air inlet 7 and a lower air inlet 15, and the mist mixing tank 1 is provided with an atomizing dry powder Atomization device. The atomization device described in this invention is a device that loosens the deposited dry powder by motive gas, reduces the dry powder into particles, and mixes the dry powder and gas to form a dry powder mist. The atomization device mixes with the mist. The lower air inlet 15 at the bottom of the tank is connected. The atomization device is composed of a coil atomizer 2 and a mushroom atomizer 4. In this embodiment, the two atomizers are used in combination, ...

Embodiment approach 2

[0046] Such as Figure 4 The mist mixing tank for dry powder fire extinguishing shown includes a mist mixing tank body 1, a powder outlet 14 is arranged on the side wall of the mist mixing tank body 1, and the top of the mist mixing tank body 1 is also provided with a mist mixing tank body The pressure detector 5 for detecting the pressure. The top and bottom of the mist mixing tank 1 are respectively provided with an upper air inlet 7 and a lower air inlet 15, and the mist mixing tank 1 is provided with an atomizing dry powder The atomization device is connected to the lower air inlet 15 at the bottom of the mist mixing tank body 1. The atomization device described in this embodiment is the coil atomizer 2, and the mist mixing tank body 1 A distribution device for distributing the power gas source is provided on the outside, and the distribution device is connected to the upper air inlet 7 and the lower air inlet 15 at the same time. The inside of the mist mixing tank 1 is also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com