Round silencer assembly welding tooling

A technology for assembling welding tooling and mufflers, applied in the field of tooling and fixtures, can solve the problems of material and resource waste, large errors, unqualified, etc., and achieve the effects of convenient clamping and disassembly, simple structure, and improved product qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

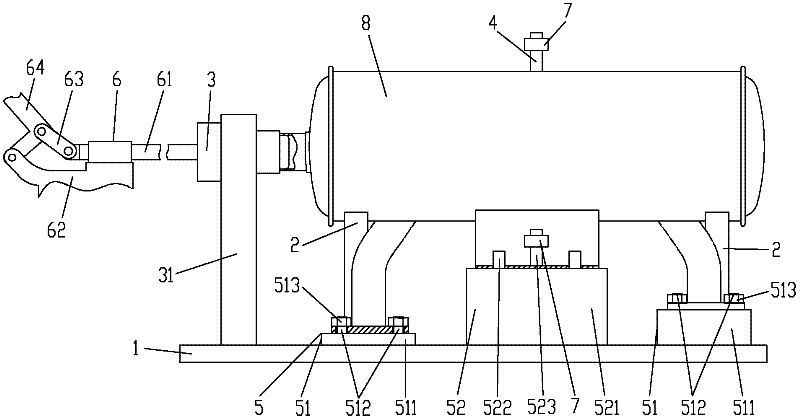

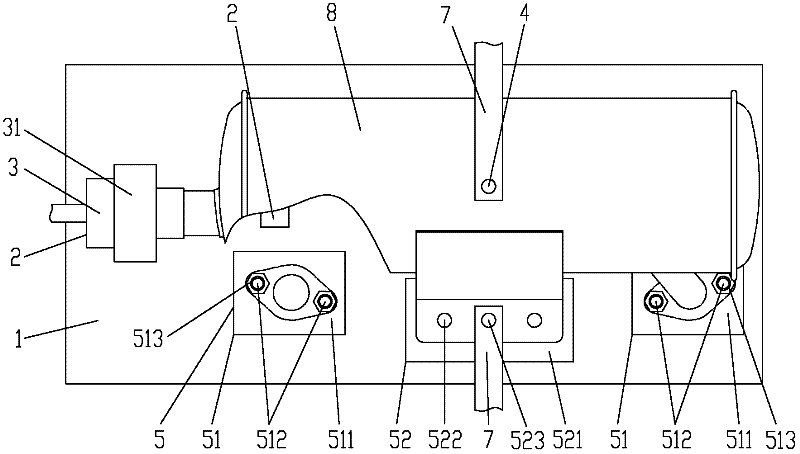

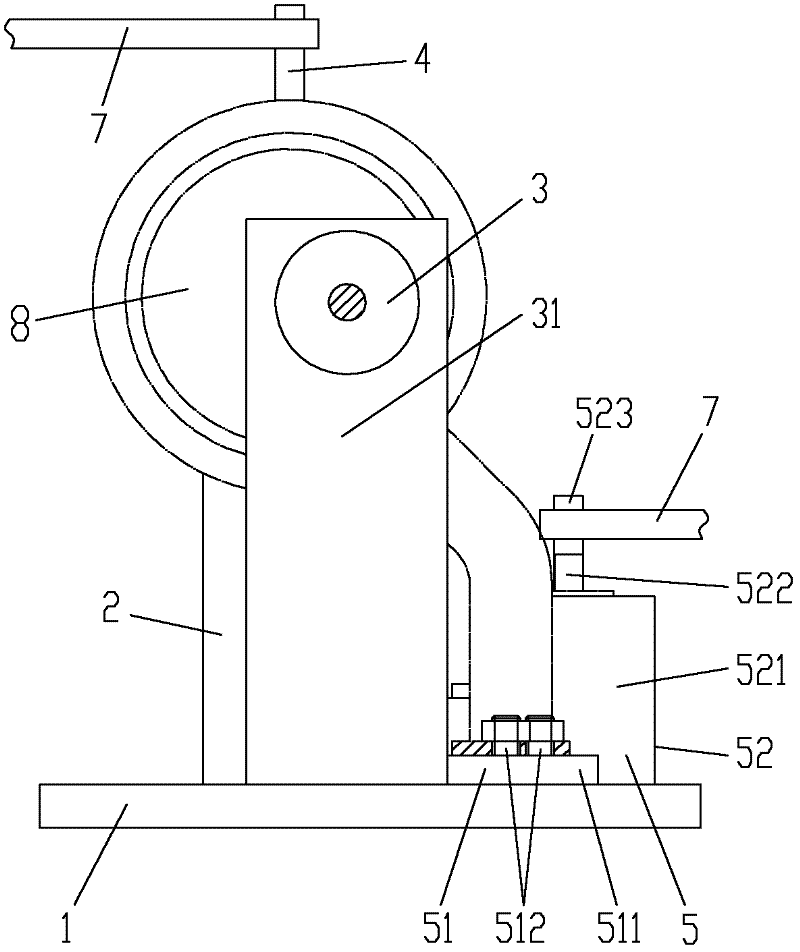

[0017] figure 1 It is the front view of the present invention, figure 2 It is a top view of the present invention, image 3 It is the left view of the present invention, as shown in the figure: the circular muffler assembly welding tool of the present invention includes a bottom plate 1, a V-shaped support block 2, a horizontal positioning pin 3, a pressing block 4 and a pressing positioning block 5, the The V-shaped support block 2, the horizontal positioning pin 3 and the pressing block 4 are used to position the muffler outer cylinder 8 that needs to be assembled and welded. The V-shaped support block 2 is fixed on the bottom plate 1 with its V-shaped face facing up, and is used to support the muffler. The outer cylinder 8, the horizontal positioning pin 3 corresponding to the position of the exhaust pipe of the muffler outer cylinder 6 is set along the axis of the exhaust pipe and connected to the bottom plate 1 through the support plate 31, and the horizontal positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com