Rectangular silencer assembly welding tooling

A technology for assembling welding fixtures and mufflers, which is applied in the field of fixtures and fixtures, can solve the problems of unsmooth installation of mufflers, waste of materials and resources, and large errors, and achieve the effects of improving welding efficiency and quality, reducing labor intensity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

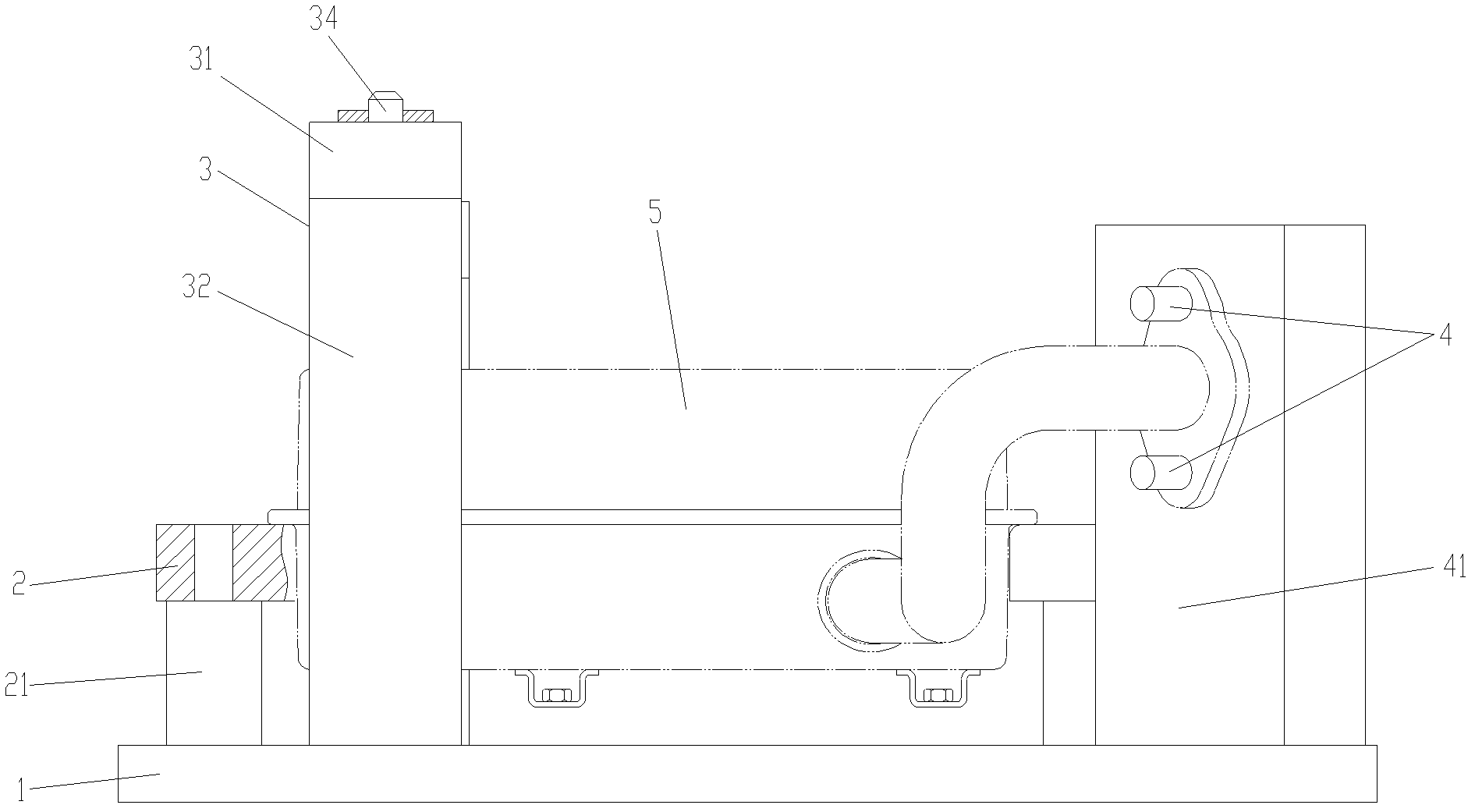

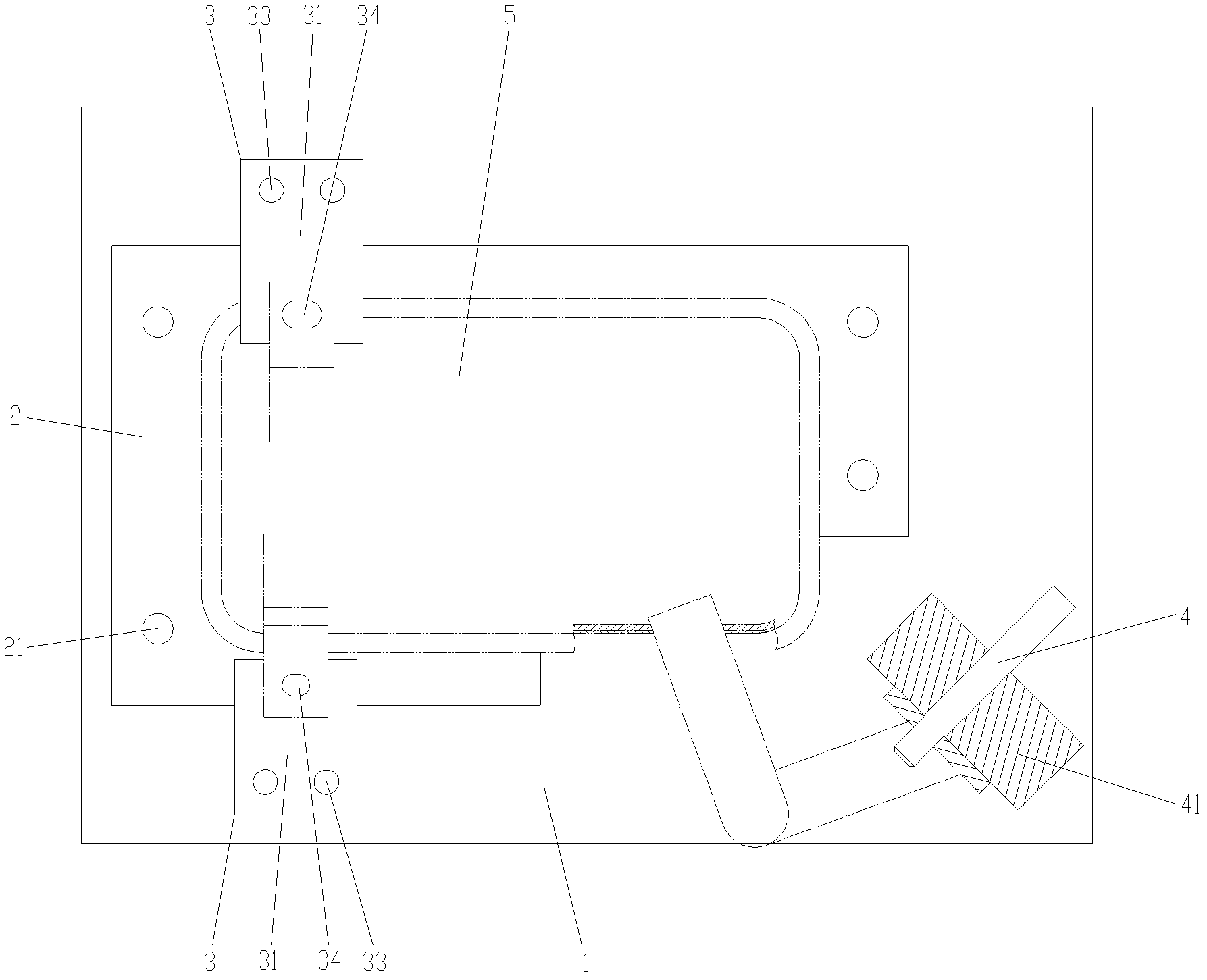

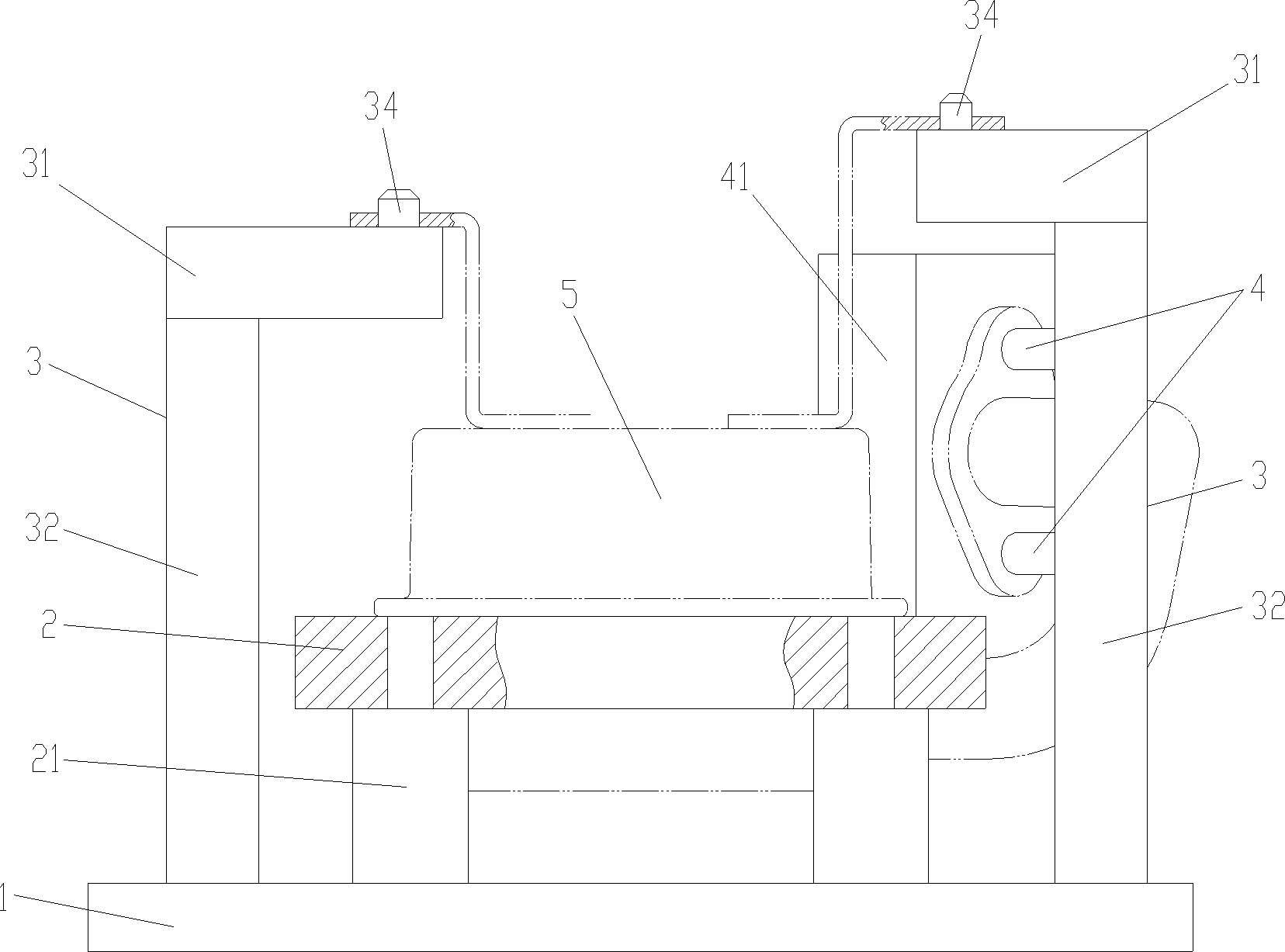

[0014] figure 1 It is the front view of the present invention, figure 2 It is a top view of the present invention, image 3 It is the left side view of the present invention, as shown in the figure: the rectangular muffler assembly welding tool of the present invention includes a base plate 1, a positioning frame 2, a supporting positioning block 3 and a positioning pin 4, and the positioning frame 2 is the internal contour and the required positioning. The outer shape of the muffler housing 5 matches the semi-surrounding support frame, as shown in the figure: the junction of the upper and lower rectangular shells of the muffler housing 5 is bent outward to form a rim, and the muffler housing 5 Place it flat on the positioning frame 2, realize the vertical direction positioning through the support of the positioning frame 2 on the edge of the muffler housing 5, and realize the horizontal direction positioning through the cooperation of the inner contour of the positioning fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com